|

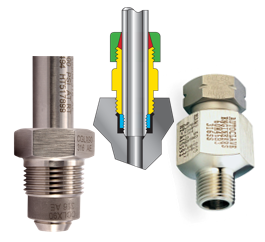

Parker Instrumentation Fittings are

Specialized for high pressure, ensures safety and provide reliable performance

Parker has decades of experience in high pressure applications, minimizing all risks related to corrosion and pressure, and is safe and reliable in the field. A diverse product portfolio provides a way for customers to identify and solve problems in hydrogen applications.

50 YEARS ADVANCING HYDROGEN TECHNOLOGY

Fueled by a robust product portfolio, Parker's support of hydrogen technology innovation has lasted more than a half century. Our experience helping customers solve for hydrogen’s complexities dates to the '60s. By enabling safe, effective production of hydrogen technology, Parker is helping that same clean energy technology power countless organizations today.

PARKER HYDROGEN PRODUCTION & TRANSPORTATION APPLICATIONS

GRAY, BLUE AND GREEN H2

We're at the forefront of hydrogen generation of every color. As market leaders in natural gas technologies and renewable energy production, we're partnering to provide systems support across the spectrum by helping the market migrate from gray to zero-carbon green hydrogen.

BALANCE OF PLANT SOLUTIONS

Parker helps our global customers optimize their hydrogen subsystems by providing a broad range of components proven to perform in the most challenging high pressure, low-temperature environments needed for gas or liquid preparation and storage.

HYDROGEN REFUELING STATIONS

As hydrogen emerges as a leading alternative fuel, refueling safety becomes paramount. Refueling station components must meet demanding performance criteria. Parker products meet that criterion and more. Our high-pressure needle and check valves have already achieved ISO 19880-3 certification.

Parker's Hydrogen Fittings are

- Parker's instrumentation are applied to Hydrogen value chain from production, transportation, storage, infrastructure_refueling station to the onboard.

- Parker provides standardized products and has received domestic KOLAS certification, KS B ISO 19880-3 certification, and European EC-79 certification to prove product quality and performance.

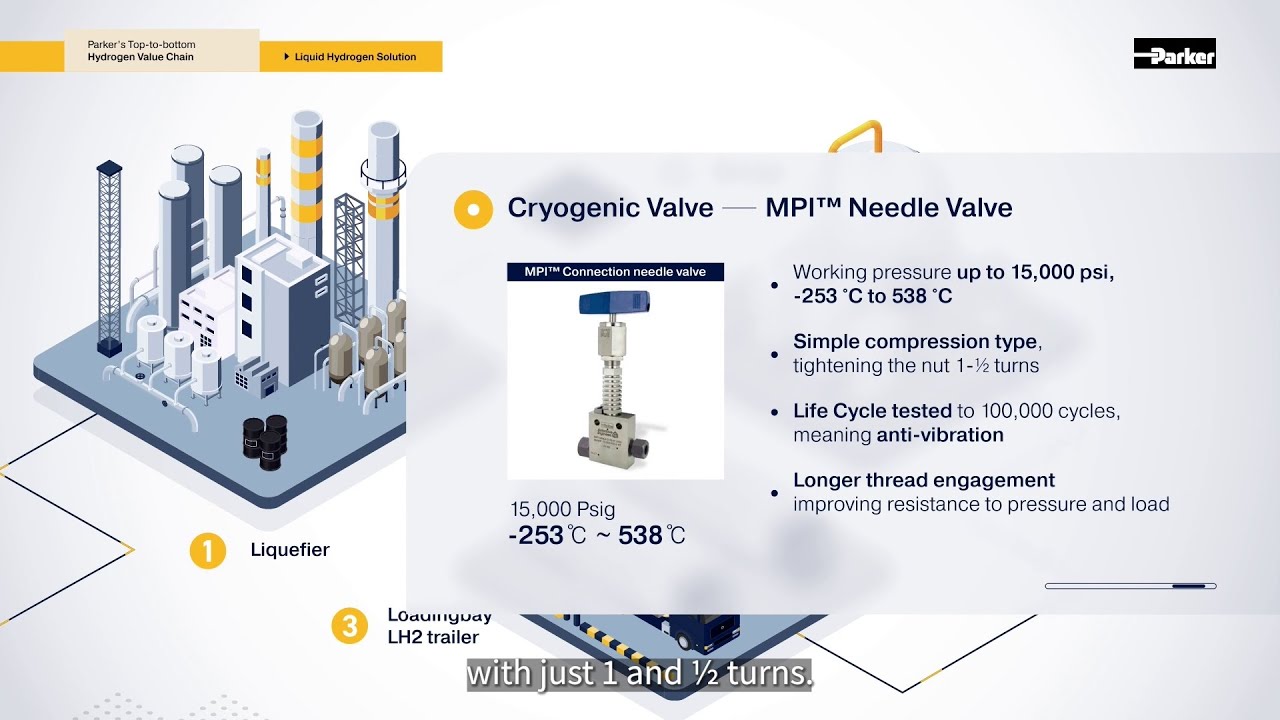

- Parker provide a wide range of products and sizes applicable to high, medium, and low pressures, as well as connection type C&T and MPI, and also provide valves and product solutions for cryogenic temperatures essential for liquid hydrogen production and transport.

- Parker offers a one-stop solution from standardized product selection and product training to installation and service in order to provide optimized services to customers.

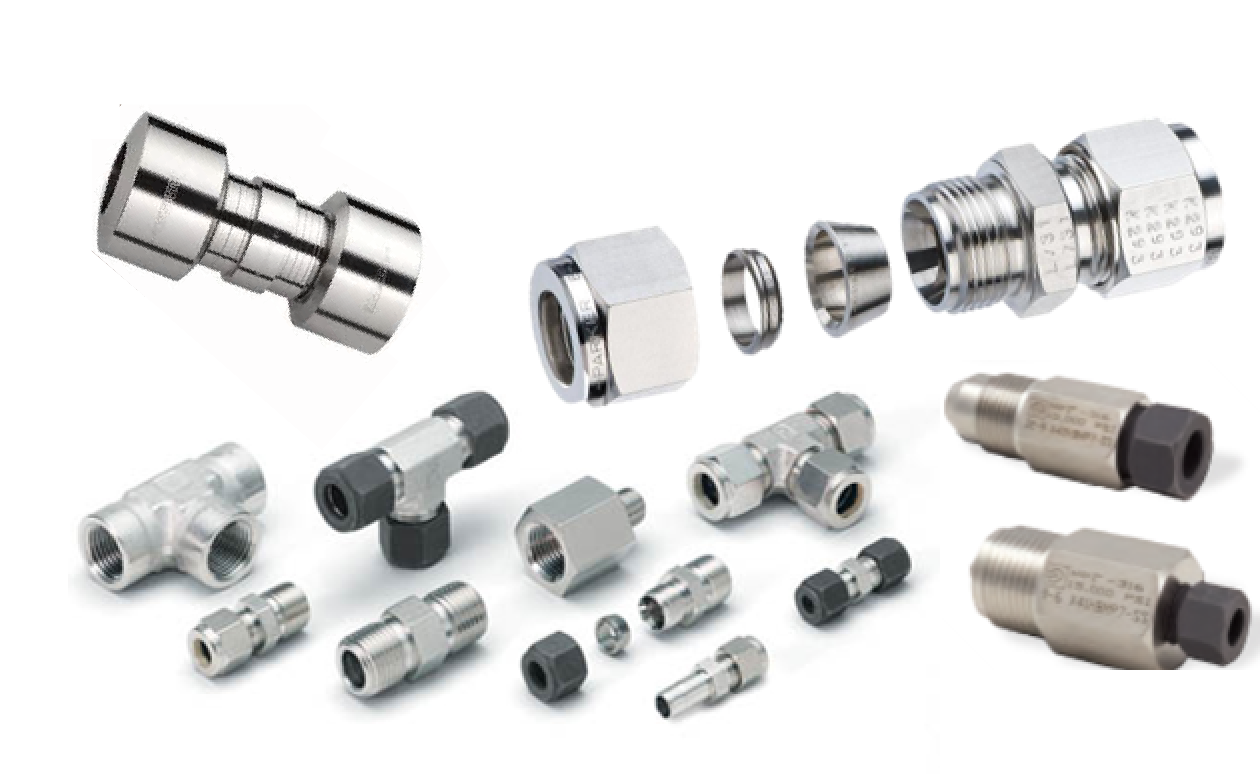

Parker Medium, High pressure Fitting

- Compression type connection

- CPI : Single ferrule fitting, easy to assemble

- A-Lok: Double Ferrule design fitting

- Size available 1/4"~1"

- Suitable for instrumentation connect

- Compression type connection

- Applied corrosion resistant Parker Supercase®

- Working pressure 6,000psi ~ 15,000psi

- Double ferrule design prevent leak

- Suitable for small bore instrument application

- Cone & Thread connection type

- Working pressure Max 60,000psi

- Stainless steel 316 SS or 2507 Super duplex material available

- Suitable for large flow rate

- Ferrule less, Non welding High pressure Fitting

- Working pressure Max 10,000psi, Working temp. -45°C ~ 93°C

- Save cost & assemble time and increase safety

- Patent sealing ensures leak free performance

Parker Hydrogen Valves & Tube

- KS Crtified Products (KS B ISO 19880-3 )

- Operating Pressure max.1,380bar, temp.-73°C ~ +316°C

- Size 1/4" ~ 1" available

- Vertical or Horizontal as required. Flow Direction arrow on valve body

- KOLAS pass, KS pending

- Operating Pressure max. 700bar, temp. -73°C ~ +316°C

- Cone & Thread or MPITM connection available

- Unique stem/seat packaging design

- Operating Pressure max 15,000PSI, suitable for medium pressure

- valves can be used with liquid, gas or chemical

- Stainless steel 316SS or 2507, Super Duplex available

- Operating Pressure max. 700bar, temp. -40°C ~ +120°C

- Europe onboard EC-79 certified

- Size 1/4~1 1/2" avilable

- Stainless steel 316SS , Super Duplex available

H2 technical blog article

Parker achieved KS certification for CXO Check valves !

Parker Korea of Parker Hannifin Corp.announces that it had obtained KS (KS B ISO 19880-3) product certification for a check valve for a hydrogen fueling station.

The product that obtained KS certification is Parker Hannifin IPD, a product produced at a plant in Pennsylvania, USA. Parker Korea passed the Korea Gas Safety Corporation's KOLAS certification test for check valves and needle valves for the first time in Korea in 2020.

There are five types of check valves that Parker Korea has obtained KS certification for this time: 1/4 inch, 3/8 inch, 9/16 inch, 3/4 inch, and 1 inch. Among them, 3/4" and 1" sizes are available for commercial vehicle fueling stations that require large flow rates.

Download H2 Catalog & White paper

Parker Hannifin are committed to supporting the energy transition and safe deployment of Hydrogen as an environmentally friendly future fuel source. And the hydrogen revolution is happening now.

Parker, as a technical expert in process control and hydrogen industry, we provide trend and reliable technology. Find out Hydrogen solution through Catalog and White papaer.

Please submit below form for Catalog download or any inquiry. We will get back to you as soon as possible

Parker Hydrogen Solution Video

Parker Instrumentation and Hydrogen Solution

Instrument Solutions for the Hydrogen Transportation Market