|

Parker is a leading manufacturer of fluid control for liquid & Gas process control and application.

Ultra High Purity products are Specialized for Semiconductor industry, ensures safety and provide reliable performance

PARKER SEMICONDUCTOR FLUID CONTROL APPLICATIONS

VMBs/ CMBs

VMB is a device that distributes special gases safely and stably to semiconductor production equipment.

Gas Cabinet

Gas cabinets are used to store Gas Cylinders and delivery hazardous gases to process equipment.

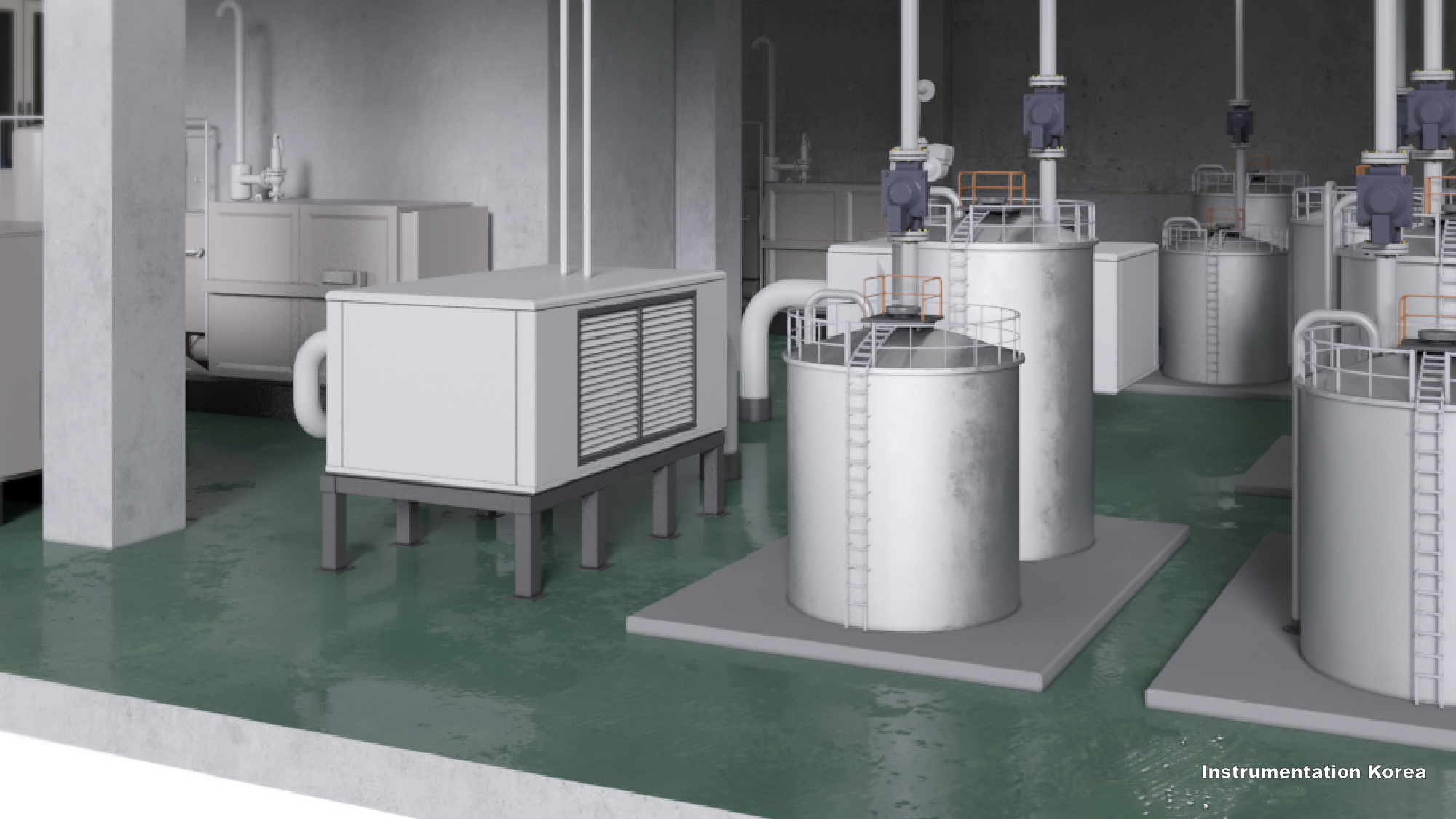

Specialty Chemicals

CCSS / SDS is a device that safely and stably supplies special chemicals/slurries to semiconductor production equipment.

Bulk Gas / BCBS

BSGS is designed to distribute gases to one or two bulk supply distribution systems, such as large cylinders, Y-type cylinders or receiver trailer.

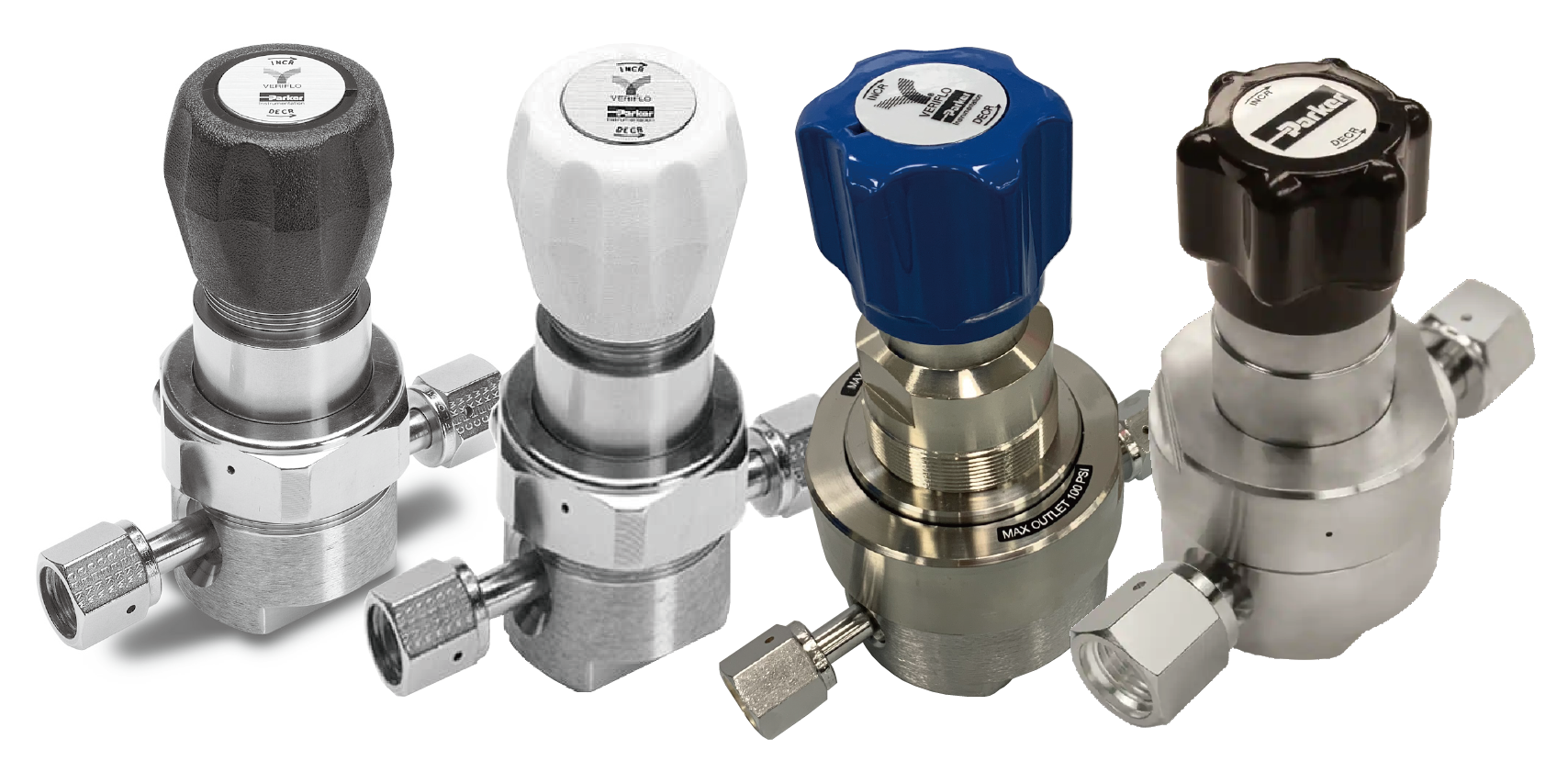

PARKER UHP Regulator

- PARKER's Veriflo Division is a leading provider of diaphragms and bulk gas valves, regulators for fluid control of the liquids and gases

- UHP products are manufactured and packaged in state-of-the-art Class 100 cleanrooms and assembly room and are made with materials such as Vericlean and Hastelloy C-22® for excellent compatibility with high flow corrosive gases.

- Parker's products, which are specialized in OEMs and most processes, as well as VMBs/ CMBs and GAS cabinets, guarantee stable performance, and have a variety of portfolio lines covering from high flow to low flow and from high pressure to low pressure.

- SQ 140 regulator for Point of use

- FR1400 for high pressure and flow

- Improved leak protection, QR 4000

- Tied Diaphragm for added safety, 959

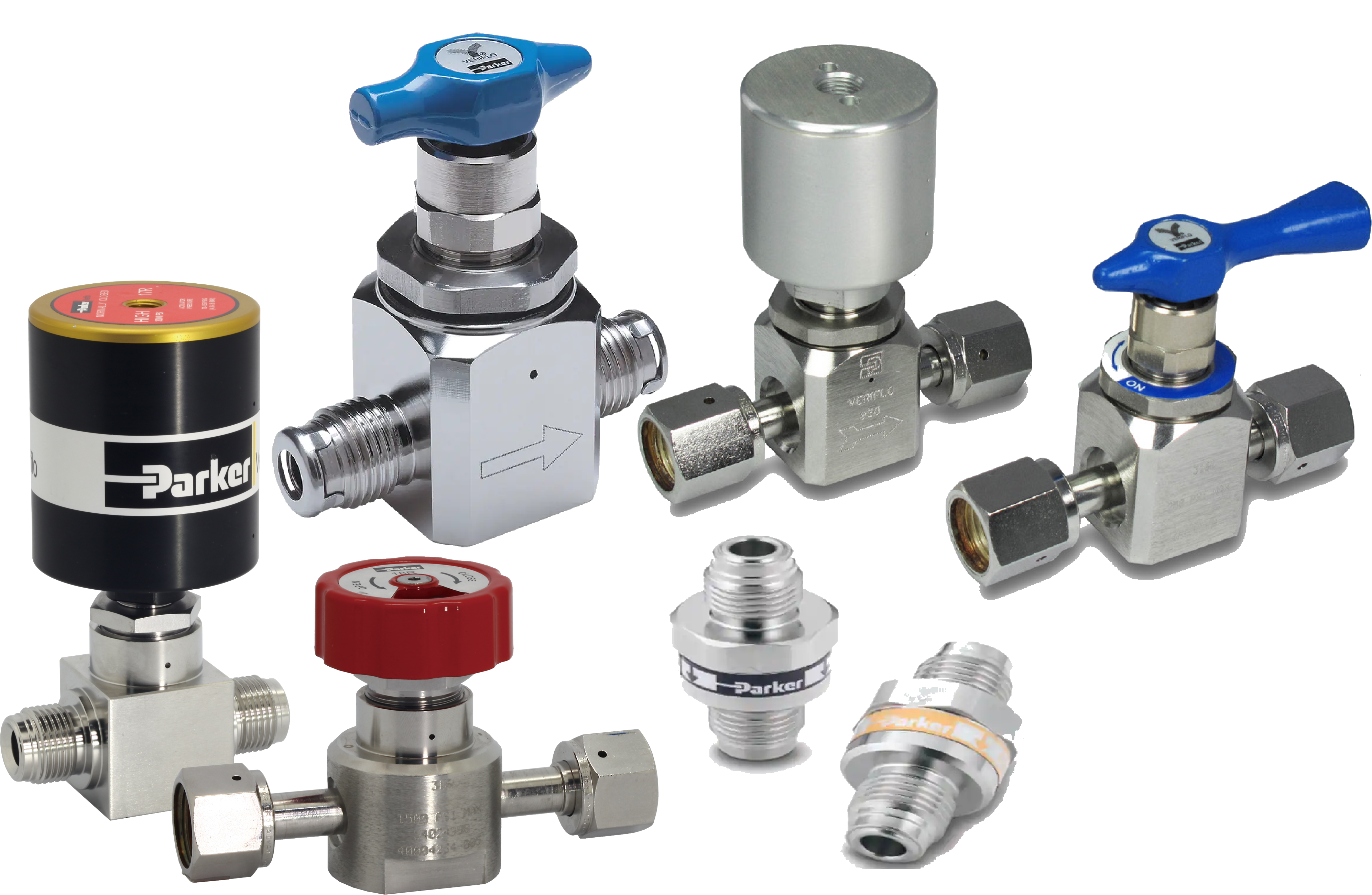

PARKER UHP Diaphragm Valve & Check valve

- PARKER's Veriflo Division is a leading provider of diaphragms and bulk gas valves, regulators for fluid control of the liquids and gases

- A diverse product portfolio that covers not only normal flow rates but also maximum flow rates of 1.30 Cv (18R) and operating pressures from 300 Psig to 3,500 Psig high pressures.

- UHP diaphragm valves has threadless and springless design in contact with the process fluid, minimizing particle generation and contamination and ensuring long service life.

- Excellent leak integrity and corrosion resistance, 930 diaphragm valve

- Springless&Threadless design minimize particle generation, 945 diaphragm valve

- Reliable performance, covering High flow and high pressure 17R, 18R Valve

- Noise free operation with the patented spring design, F9 Check valve

UHP PFA & PTFE Regulator, Valve & Fitting

- PFA & PTFE products are ideal for ultra-high purity (UHP) and corrosive chemical handling systems including fab equipment connections

- Made of high-purity (UHP) PFA or PTFE, it minimizes the generation of surface particles, total organic carbon (TOC), resulting in excellent performance and reliable results in work where cleanliness is important.

- Stainless steel spring coated with fluoropolymer boasts strong corrosion resistance and is compatible with many process fluids

- Tong & groove seal protects Spring and thread , PR-1 PTFE Regulator

- Minimize the particle and contamination of fluid, PFA Parflare Fitting

- Fully functional to 100psi, MV-13 PFA Needle Valve

- Custom Assembly available CASY

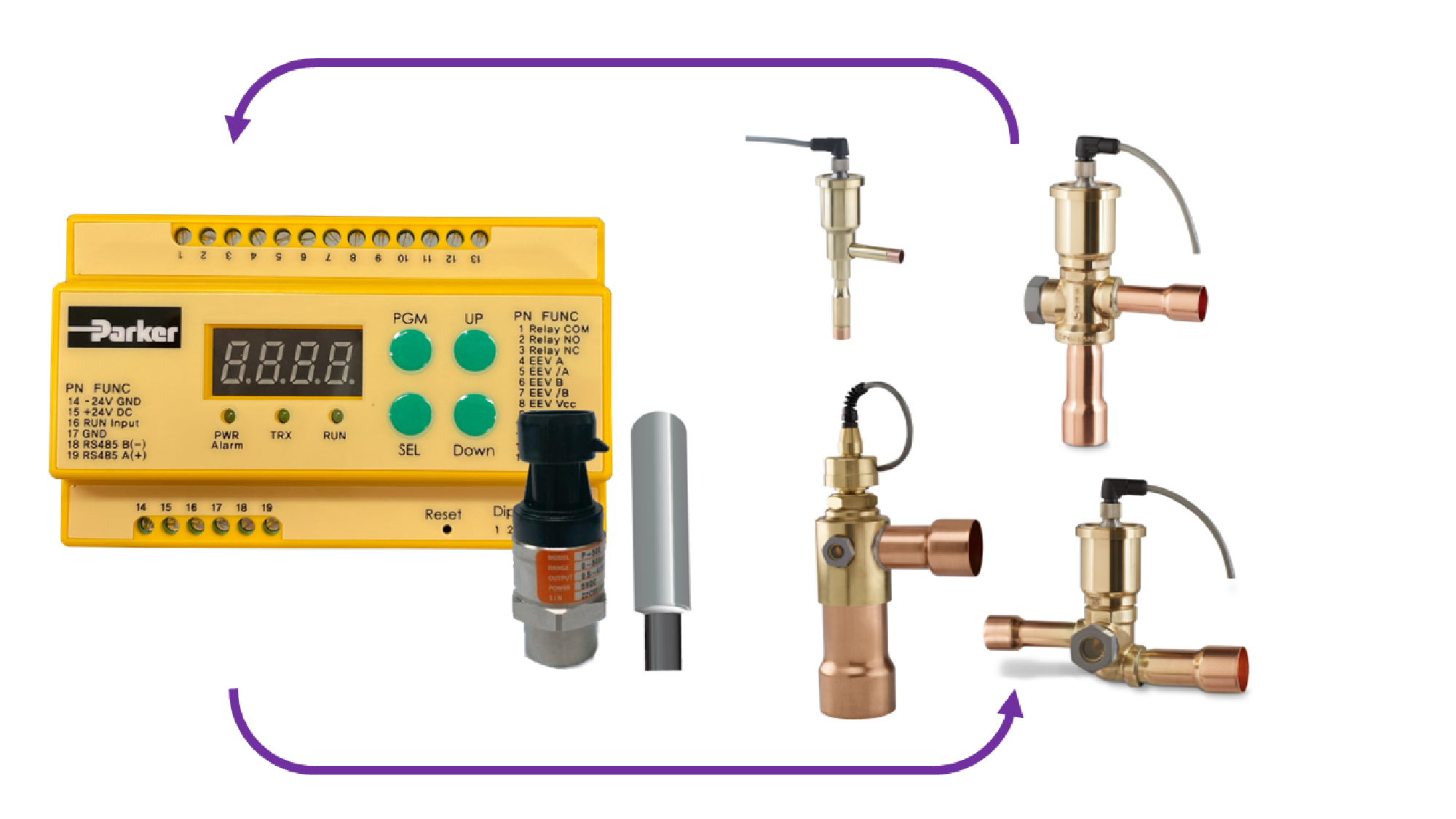

PARKER Refrigerant & Temperature Control System

- Ideal for Semiconductor chiller or any precise control is needed, APK Superheat Controller

- Boasts fast response and reliability, and can control various conditions such as voltage, current, and valve speed with one integrated interface board IB-K

- SER bipolar electronic expansion valve, solenoid tight seating to prevent leakage and corrosion resistance by using anti-corrosion materials

- SDR bypass discharge valve, capable of interfacing with direct digital control or building management systems

- MTW electronic 3-way control valve, simplifies piping material cost, installation time, and piping complexity with simplified system piping

TRENDS IN SEMICONDUCTORS

The U.S. semiconductor industry has seen its share of ups and downs. But the near future looks strong with the demand for chips only growing from a multitude of industries. Keeping up with growing demand and technology advancements will propel semiconductors forward in Industry 4.0, the new digital age of manufacturing.

This white paper explores:

- Applications driving growth.

- Global semiconductor shortage.

- The U.S. Government's commitment to increasing America's self-reliance in semiconductor production.

- Global capacity additions.

- Specialized semiconductor manufacturing equipment.

- Recent advancements in semiconductor technology.

- ALD and ALE processes.

- Contamination control.

Please fill out below form to download Semiconductor FAB application & Semiconductor industry trend white paper or any other technical inquiries.

Parker Semiconductor Solution Video

Instrument Solutions for Gas Delivery System

Instrument Solutions for Chemical Delivery System

Parker Hannifin

Instrumentation Asia pacific

Marketing Communication

© PARKER HANNIFIN CORP 2023