GENERAL PURPOSE CLIPPER® OIL SEALS

SPLIT CLIPPER® OIL SEALS

HIGH MISALIGNMENT CLIPPER® OIL SEALS

WIDE SELECTION OF PROFILES AND SIZES NOW AVAILABLE FOR ONLINE PURCHASE

Clipper® Oil Seals from Parker can now be purchased online.

Repairing or building equipment and need a rotary shaft seal? Genuine Clipper Oil Seals from Parker can now be purchased online and shipped to you ― in exactly the quantity you need!

No minimum order quantity on select sizes.

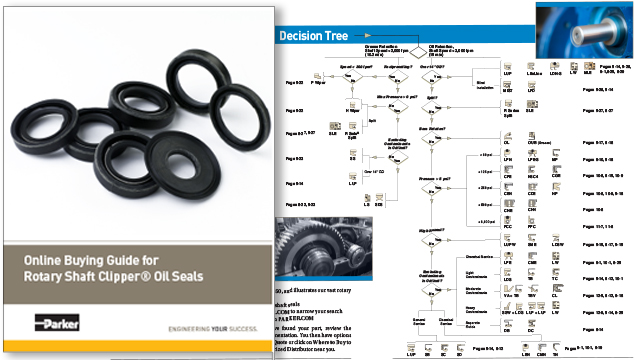

View the Product Selection & Buying Guide decision tree with listing of part numbers available for online purchase.

See below for features of the most common, widely used Clipper Oil Seal profiles.

Product Selection

REPLACEMENT AND ORIGINAL EQUIPMENT SEALS FOR

PUMPS | MOTORS & GENERATORS | SPEED REDUCERS | HEAVY DUTY EQUIPMENT | MARINE | PERFORMANCE CRITICAL EQUIPMENT

MINING | PAPER | STEEL | CRUSHERS | FANS | WORK ROLLS | COMPRESSORS | OVERHEAD CRANES | MINE CART WHEELS | FLYWHEELS | DRAG LINES | HOISTS | IDLER WHEELS | CUSTOM EQUIPMENT

MOST POPULAR, WIDELY USED PROFILES

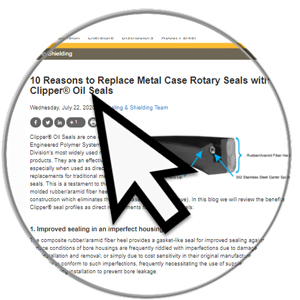

GENERAL PURPOSE

General Purpose Clipper Oil Seals (LUP, LPD, RUP, RPD)

Great performer ― from general purpose to heavy duty applications.

- Corrosion resistant composite O.D. and SS spring are standard

- Available with external lip for light dust/fluid exclusion

- Profiles available with spring retention feature for blind installation

- Easy installation; no special tools required

- Available for shaft sizes from 1/2" to 60" diameter

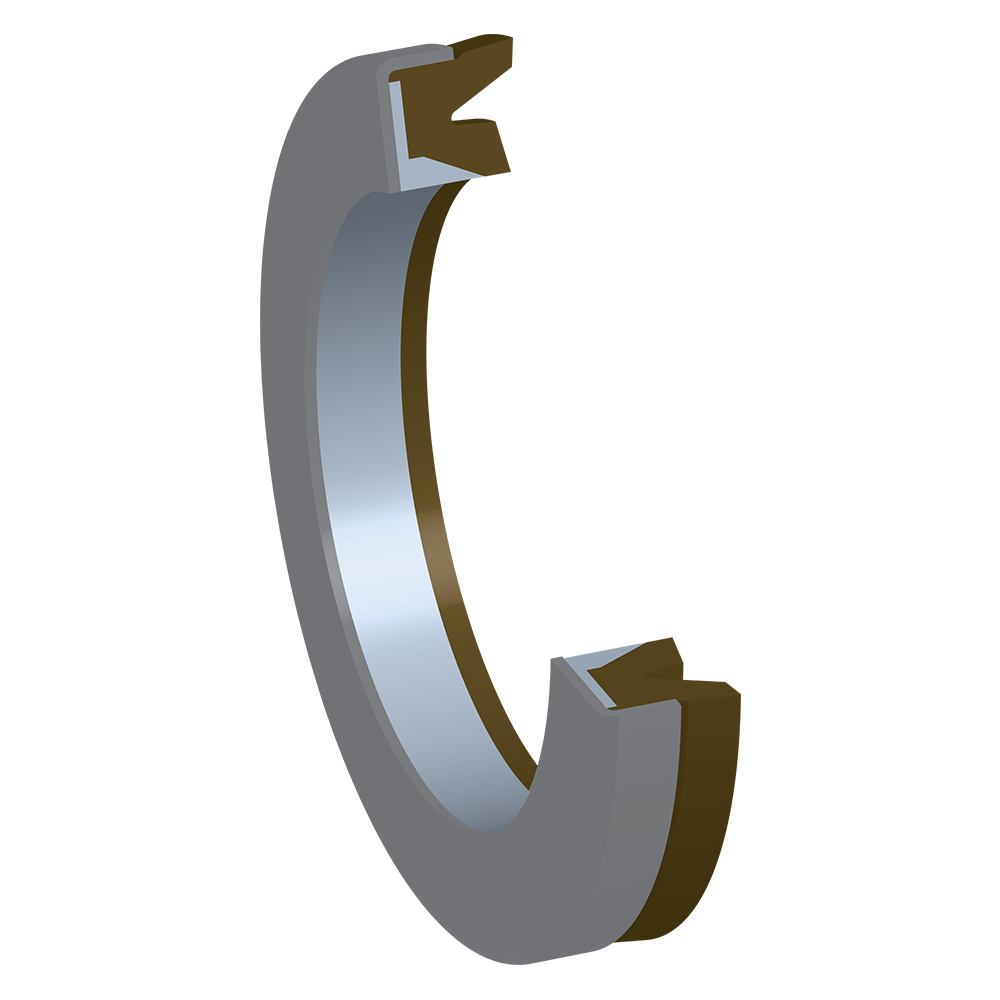

FACTORY SPLIT

Seal replacement solution does not require equipment disassembly.

- Precision calculated factory split

- Easy to install; no special tools needed (VIEW INSTALLATION VIDEO)

- In field replacement; no need to uncouple equipment

- Reduce production downtime

- Extend up-time between scheduled rebuild cycles

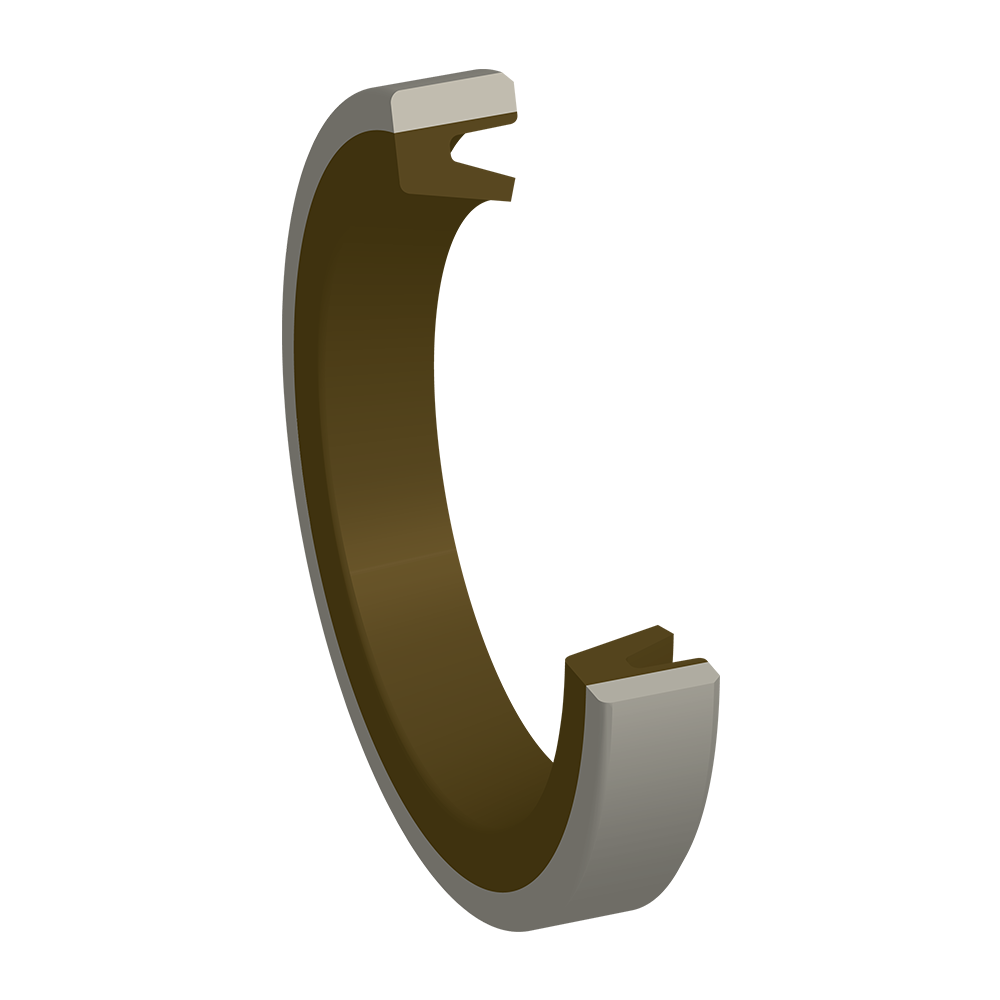

HIGH MISALIGNMENT

Extended lip accommodates misalignment and high runout conditions

- Capable of handling applications with runout conditions up to 1" total eccentricity

- For oil retention and low speed

- No coverplate required

- Available for shaft sizes from 1" to 65" diameter

SHALLOW CAVITY, GEN. PURPOSE WIPER

- Springless elastomer lip, composite elastomer/aramid fiber heel

- General purpose exclusion of dust and contamination

- Reciprocating shaft surface speeds up to 300 fpm (may require bore plate)

- Rotating shaft surface speeds up to 2000 fpm

COMPACT WIPER PROFILE

- Reciprocating service

- Low surface speeds up to 300 fpm

- Lip extends outside bore face (cover plate may be required)

HEAVY CONTAMINATION EXCLUDER

- Rides against face of housing to keep contamination away from primary seal

- Composite elastomer/aramid fiber heel conforms to shaft surface imperfections for leak-free performance

- Severe dust and contamination environments

- External washdown

HIGH PRESSURE, HIGH TEMP

- FKM (fluorocarbon) sealing lip rated up to 400°F

- Metal Case with PTFE back-up element manages high pressure systems to 300 psi

- Shaft surface speeds up to 4,000 sfpm

LIGHT DUTY, GREASE RETENTION

- Single elastomer lip

- Composite elastomer/aramid-fiber outer case forms leak-free, press fit in the housing

- Conforms to minor housing surface irregularities

- Shaft surface speed up to 2,000 sfpm

- Max pressure of 0-7 psi, depending on shaft speed

STATIONARY SHAFT, ROTATING BORE

- Rotating bore applications

- Available in springless and spring-loaded designs

- Commonly used in conveyors, agriculture, and ground-engaging equipment

- OL-SS, OL-LUP, OL-LDS, OL-LPD, OL-R-series

RESOURCES

BUYING GUIDE

WE CAN WORK WITH YOU TO DESIGN A CUSTOM SOLUTION. FILL OUT AND SEND US THE DESIGN REQUEST FORM. CLICK TO DOWNLOAD FORM