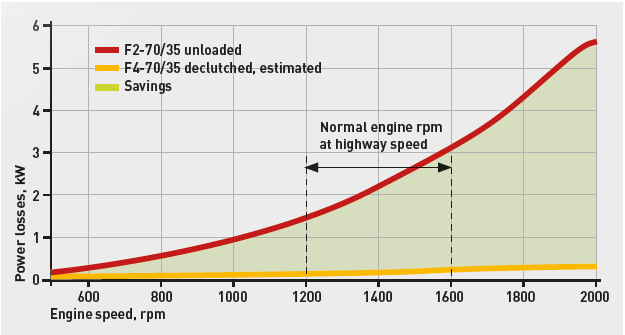

Substantial fuel savings and reduced emissions

An example from the real world: A new Volvo FH-13 skip loader with a detachable snow plough ran for 260 hours in its first month, using the PTO for just 56 of those hours. Around 1.2 kW per hour less power required when the pump is disconnected equals about 50 litres less fuel needed in that month alone – in a year, the possible savings could exceed 600 litres by a wide margin, since the snow plough is in use only for a few of those months. The CO2 emissions are also reduced by around 1.8 tonnes.

Longer service life, lower cost

Disengaging the pump also reduces wear and tear on the pump and minimizes the risk of costly downtime and standstills, while also reducing the noise level. All by just pressing a switch on the dashboard, without turning the engine off.

Multi-function made easy

The new, disengageable F4 series offers a unique combination of features. The dual flow design offers a simple and flexible solution for any vehicle requiring separate flows of differing capacities – multiple function applications like salt spreaders, skip loaders, forestry cranes, sludge trucks and many others. The patented clutch fuction lets you engage and disengage the pump from the diesel engine on the fly, enabling substantial savings on fuel.

Safe limp-home

When a pump is fitted to an engine PTO, even small mishaps like a ruptured hose can result in having to be recovered and towed to a workshop, with all its downsides by way of major outlay and high downtime costs. With the new F4, you just disconnect the pump and make your way home under your own steam.

The video shows the Pump Series F3. It is the same principle and mode of action as Series F4.