Instrumentation Solutions for Hydrogen-Powered Vehicles

Helping you drive the energy evolution forward

Parker Hannifin are committed to supporting the energy transition and safe deployment of Hydrogen as an environmentally friendly future fuel source.

As a manufacturer of pressure containing equipment, Parker has decades of experience in serving hydrogen applications.

Our comprehensive product portfolio covers a wide variety of pressures to help our customers overcome some of the technical challenges of such critical and demanding application.

Parker products are designed to minimise the risk associated with corrosion and hydrogen attack, and ultimately provide safe and reliable performance in the field.

Download our promotional brochure to learn how we can support you in driving the energy evolution forward.

We Can Help you Select the Right Material.

When it comes to handling hydrogen, material and equipment selection becomes, more than ever, an essential ingredient for success. Fill in the form to be contacted by one of our material experts to help you select the right alloy for hydrogen service.

ON-VEHICLE APPLICATIONS

A-LOK® tube fittings - EC-79 Approved

up to 350 barg pressures

Parker A-LOK® two ferrule tube fittings are designed to achieve reliable, leak-free connections on-board hydrogen-powered vehicles up to 350 barg pressures. These fittings have provided proven performance in hydrogen systems for many years and are available as an integral end connections on our extended product range, including all valve types. This will reduce the need for ‘threaded’ components and therefore reduce the number of potential leak points across your installations.

Components used on-board hydrogen-powered vehicles require EC-79 certification. The EC-79 (Regulation of the European parliament and the Council of 14 January 2009) type-approval of hydrogen-powered motor is an EU normative for components and systems which are installed on hydrogen-driven vehicles.

Product ranges certified to this regulation are extensively tested to guarantee the safety and performance of hydrogen (H2) equipment under different pressures, electric, mechanical, thermal or chemical conditions.

COMPONENTS FOR INFRASTRUCTURE APPLICATIONS

For hydrogen applications which do not require on-board EC-79 certification, Parker Instrumentation offers a wide range of instrumentation and control products including:

Parker Instrumentation offers a wide range of hydrogen-compatible components for infrastructure applications:

- Storage tanks

- Dispensers

- Compressors

- Pressure control devices.

Addressing the Challenge of Hydrogen Enbrittlement in Metallurgy

Hydrogen is the most abundant element in nature and its versatility can offer compelling advantages as an accessible, sustainable and efficient alternative source of energy. However, hydrogen can be very damaging for most metallic materials, causing what is known as hydrogen damage or hydrogen attack. Hydrogen, being an extremely small particle, hydrogen degradation is directly connected to its capability to be easily absorbed by metals coupled with the high mobility those particles have at microstructural level.

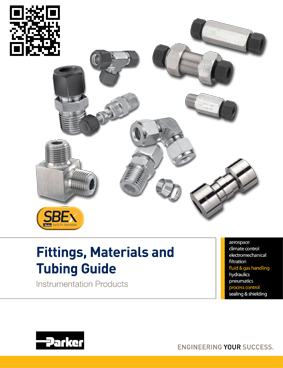

On-Site Training

At Parker, we recognise that leak-free performance is at the top of your agenda. Anyone installing Parker products for hydrogen service will be offered Small Bore Expert (SBEx) training

Parker Hannifin Manufacturing Ltd

Instrumentation Products Division Europe

Riverside Road

Barnstaple EX31 1NP

United Kingdom

phone 0044 (0) 1271 313131

Parker Hannifin Corporation

Instrumentation Products Division

1005 A Cleaner Way

Huntsville AL 35805

United States of America

phone 001 256 881 2040

Instrumentation Products Division

Autoclave Engineers Operation

8325 Hessinger Drive

Erie

Pennsylvania 16509-4679

United States of America

phone 001 814 860 5700