Mining and Tunneling Jumbo Drilling Rigs

Designed to Withstand Harsh Environments

Browse through our products that can be specified for tunneling jumbo drilling rigs. Entries include technical specifications, support materials and where to buy details.

Specified by working pressure, not construction, GlobalCore is the world’s first high-performance cohesive hose and fitting system. Designed, built, and tested to the ISO 18752 specification, the GlobalCore system simplifies specification for OEMs and end users around the globe by providing a comprehensive family of products for the most commonly used constant working pressure classes

- Parker Tracking System (PTS)

- Easy service and replacement

Parker's high-pressure screw to connect hydraulic quick couplers can connect under pressure for use in heavy duty, high impulse hydraulic applications where fluid lines require fast and easy connection and disconnection.

- Sizes from 3/8 to 2-inch

- Disconnect up to 175 bar

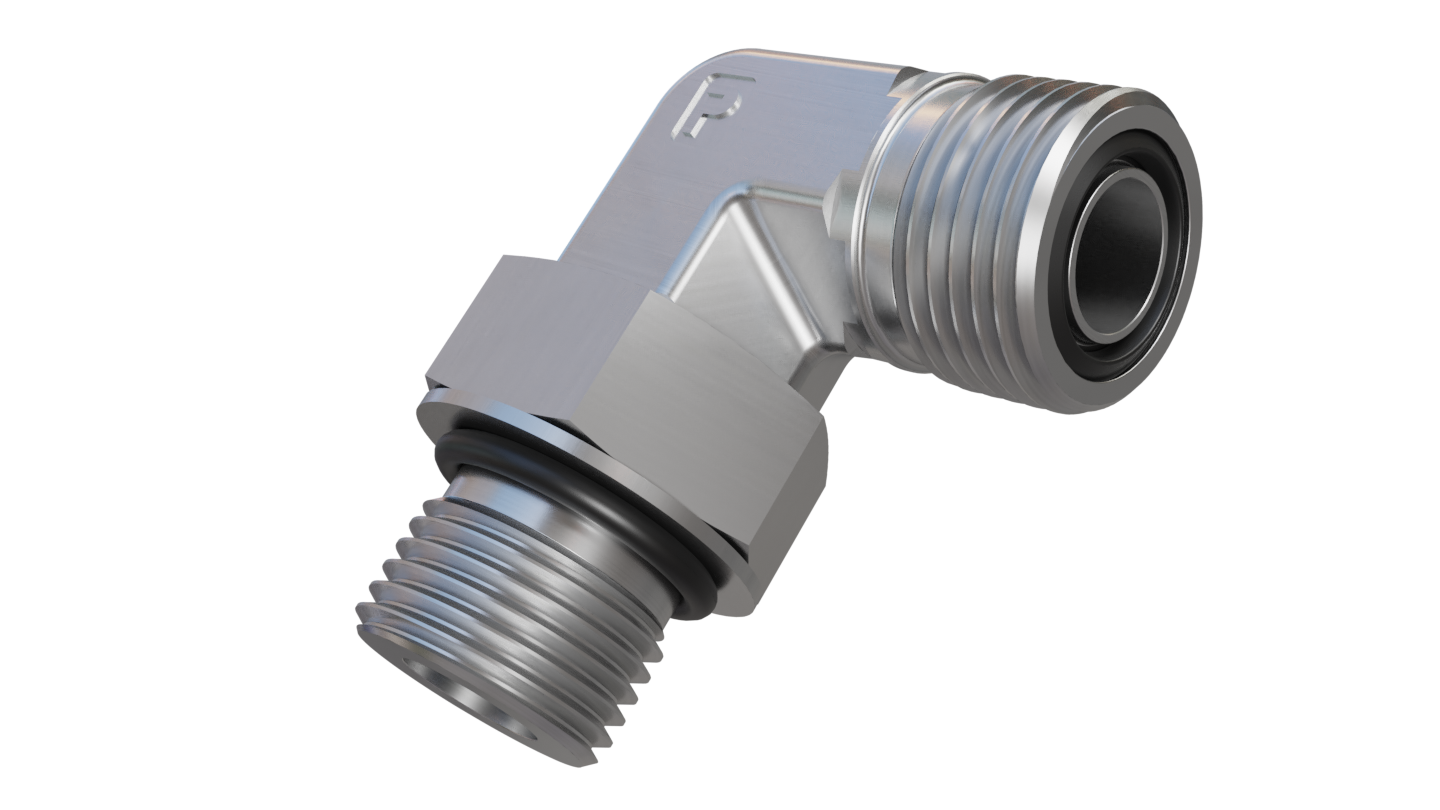

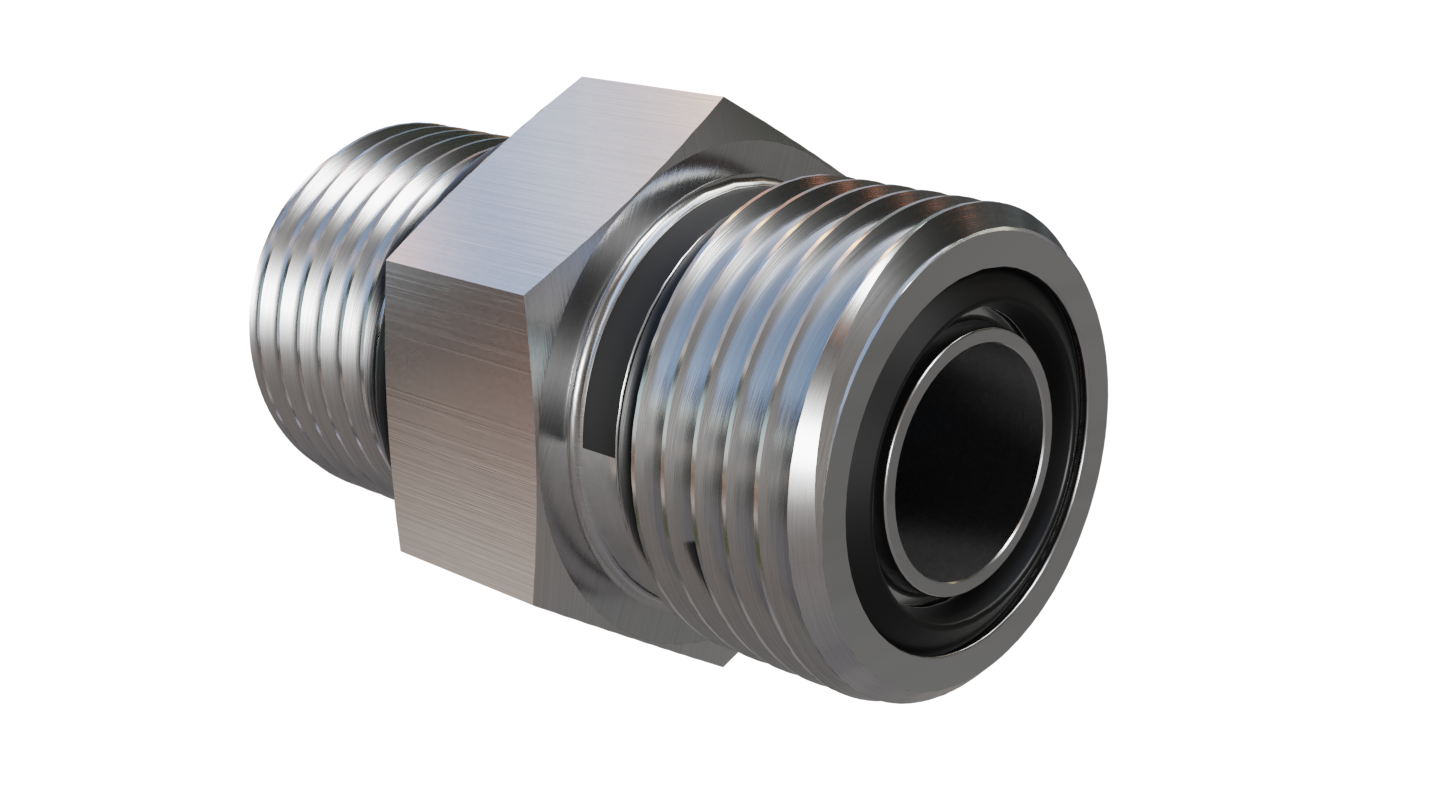

Parker's Seal-Lok O-Ring Face Seal offers a leak-free seal fitting design and a rugged construction to make it optimal for use in situations with high-pressure, vibration and impulse environments.

- Reliable leak-free ORFS connection

- Seal retention ensured with Trap-SealTM

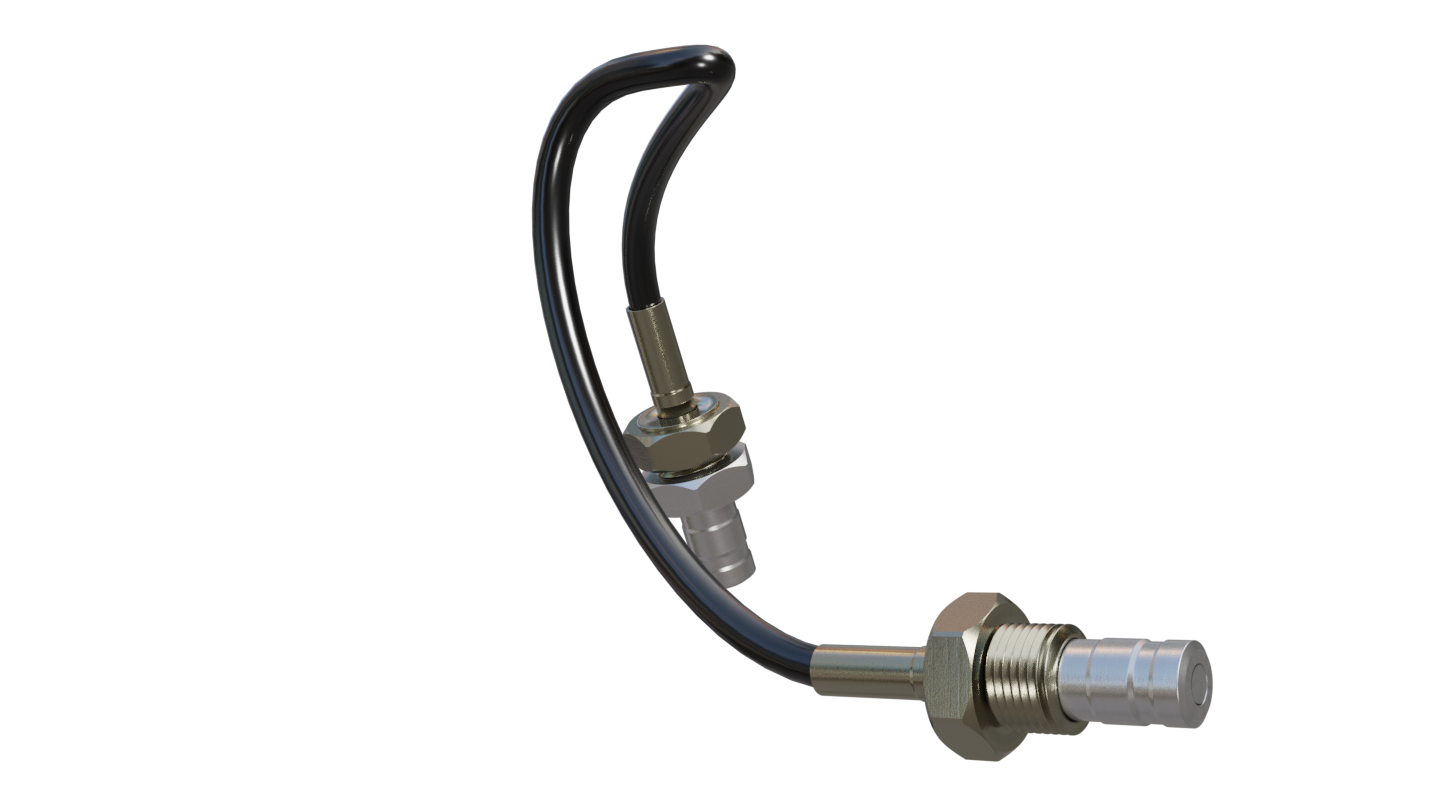

Parflex 56DH diagnostic hose offers the best in class performance by reducing the volume of fluid in the system over -4 rubber hose.

- High pressure

- Fast and accurate response

Stand up to the ravages of red rust, Parker delivers the ultimate corrosion defense. Parker ToughShield Plating, up to 1,000 hours far exceeds the 72-hour SAE requirement. Parker XTR Coating offers more than 10x the 72-hr SAE requirement for corrosion resistance including urea exposure.

- Protection for highly corrosive environments

- Significantly more corrosion resistance than SAE standard

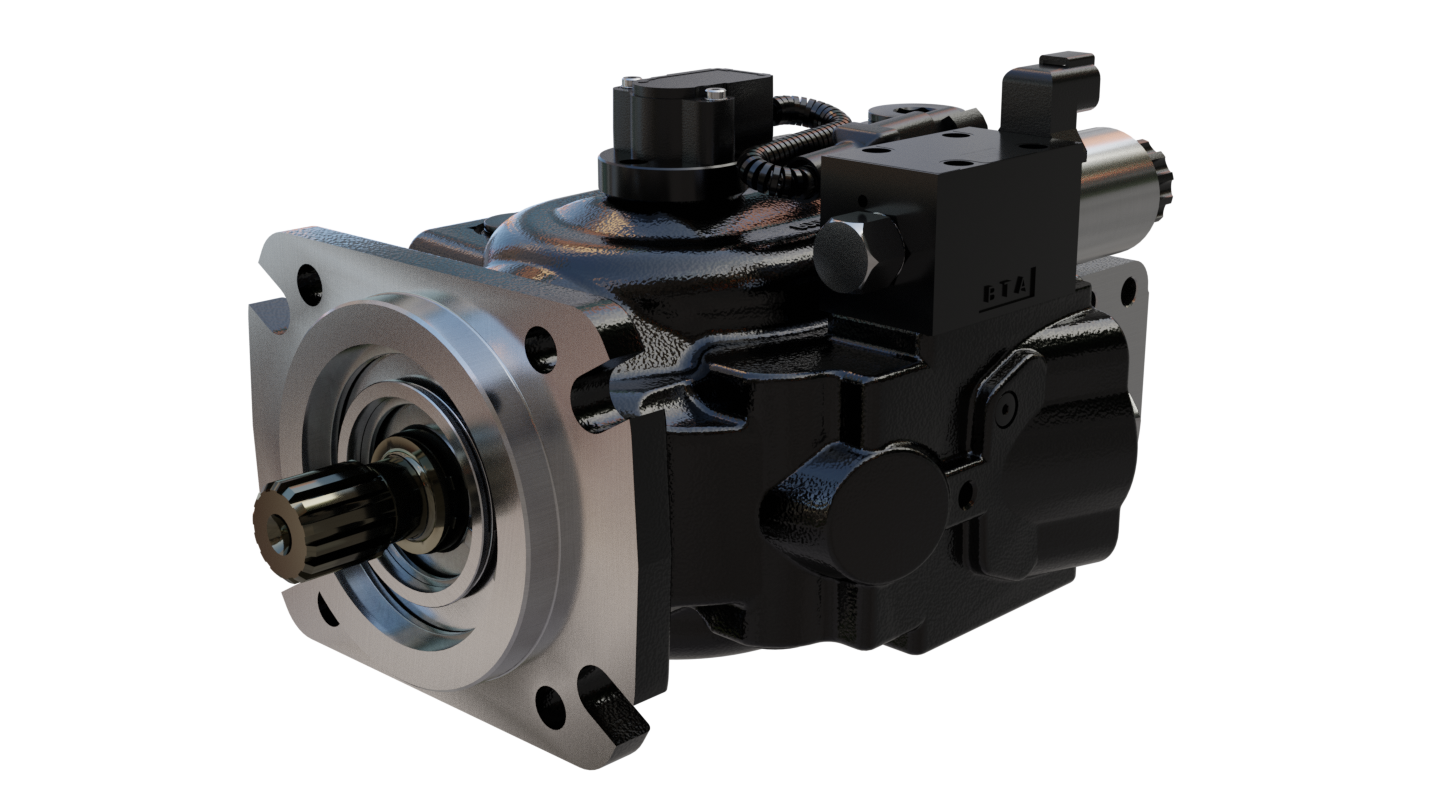

Variable, swashplate piston pumps designed for operation in open circuit, mobile hydraulic systems. Perfect choice when it comes to cost-saving installation as well as high productivity and power density. Displacements from 60 to 145 cc/rev.

- Integrated low noise ripple chamber

- Torque limiter capable

Parker L90LS mobile valve is characterized by industry leading properties regarding robustness, control precision and energy efficiency. Parker L90LS is a sectional-built, load sensing, directional control valve for mobile machinery.

- Pre-compensated

- Precise control

The M5 series is tailored for severe duty applications which require high pressure, high speed and low fluid lubricity.

- Patented cartridge design

- Double lip vane design

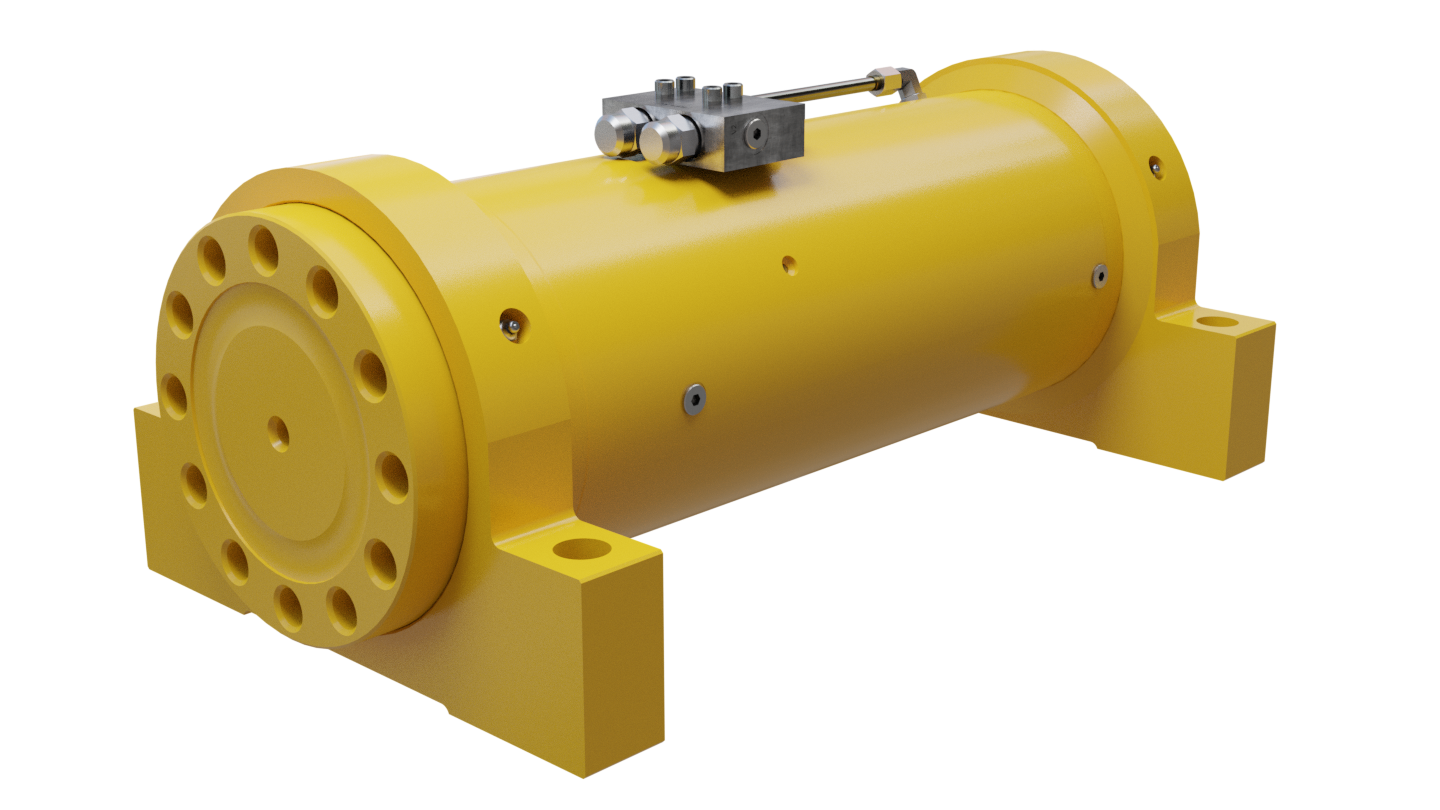

The Helac L30 Series is a heavy duty helical hydraulic rotary actuator that is suitable for harsh environments. Designed for applications that require high bearing capacity, the L30 Series features foot or flange output with 180° or 360° rotation.

- Provides rotary actuation

- High torque compact design

Parker’s UTS Universal Tilt Sensors communicate angle of tilt, pitch, and roll information using SAE J1939 CAN bus protocol. They are engineered with MEMs devices for reliability and built to withstand rugged applications.

- 3-axis precise indication

- J1939 protocol

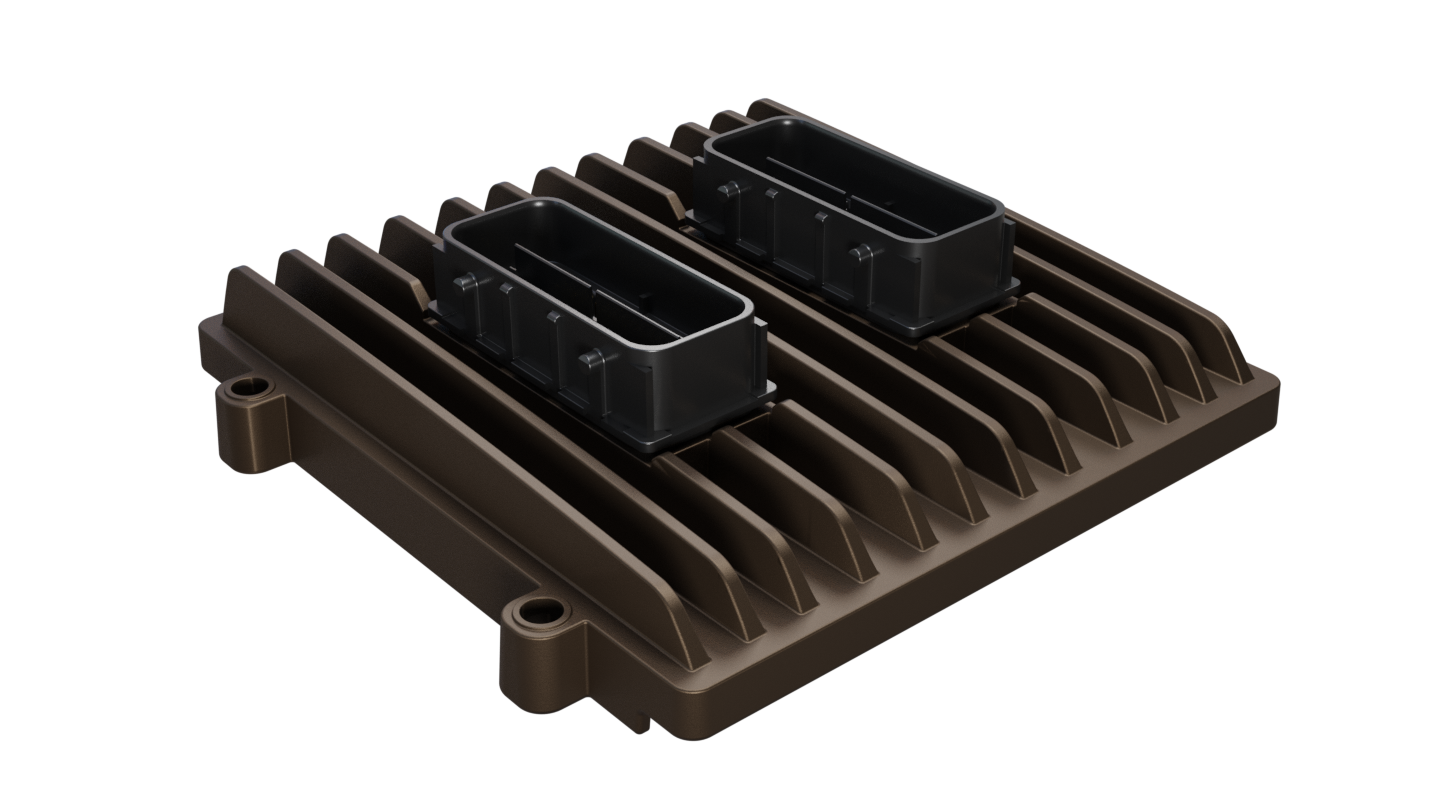

Parker’s IQAN-MC41, -MC42 and -MC43 are rugged master controllers that are designed as the ideal solution for hydraulic control systems in mobile hydraulic vehicles and machinery. Parker IQAN® master controllers enables optimized system architectures speeding development which improves OEM revenues.

- IQAN design platform

- Optimized for EH control

Parker’s IQAN-LC5-X05 is a large, analog joystick for the mobile market. The ergonomic MP handle option provides a variety of control interfaces. Combinations of buttons, thumb wheels, and trigger are available.

- CAN bus joystick

- Safety redundancy capability

Metal seals are produced in a number of standard designs which are appropriate for use in a broad spectrum of the most commonly encountered applications.

- Seals for extreme environments

- Pressure energized seal

Parker's Air Duct Seals for Heavy Duty Engines are a single piece, easy to install design, providing lower leak rates than traditional labyrinth piston ring seals.

- Single piece design

- Anti-wear TriCom HTTM coating

Parker fuel/water separators provide a simple, economical and environmentally friendly method of removing water and other particulates. This provides maximum protection for diesel engine components in applications where reliability is absolutely critical.

- Multi-stage separation

- 3 stages for maximum protection