Sandwich Valves - Series CPOM, CP, ZRE

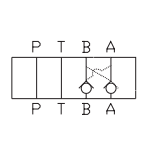

Series CPOM double pilot operated check valves block leakage from the actuator ports to tank when the directional valve is in the center position.

Series CP pilot operated check valves are designed for maximum flow rates. The valves are typically used in combination with spool type directional control valves to ensure leak free positioning of the actuator.

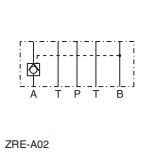

Series ZRE pilot operated check valves are designed for maximum flow rates and long life time. The valves are typically used with spool type directional control valves to ensure leak free positioning of the actuator

Why Choose the CPOM, CP, or ZRE?

- Sandwich style, pilot operated check valves can be provided in either single or double configurations.

- The pilot operated checks may be positioned in A port or B port; or both A and B ports.

- Valve bodies are manufactured from steel providing extra strength and durability for longer life. Internal hardened steel components also provide longer life.

- Positive shut-off is provided by a hardened poppet and cage assembly.

- Large internal flow paths allow high flow at low pressure drop.

These sandwich type hydraulic check valves can be used in virtually any application. They vary in flow from 14 GPM to 160 GPM, depending on the subseries and pressure chosen. Specific technical data can be found below.

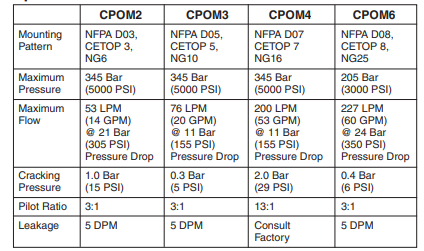

CPOM Specifications

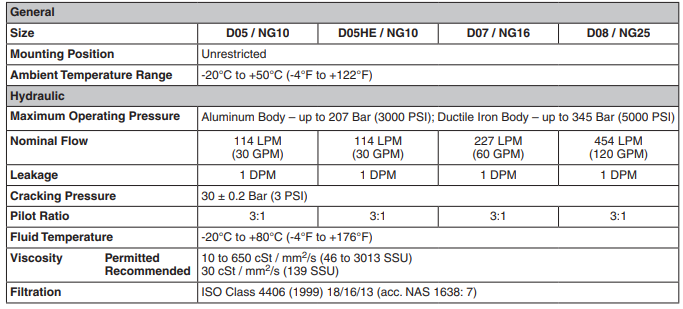

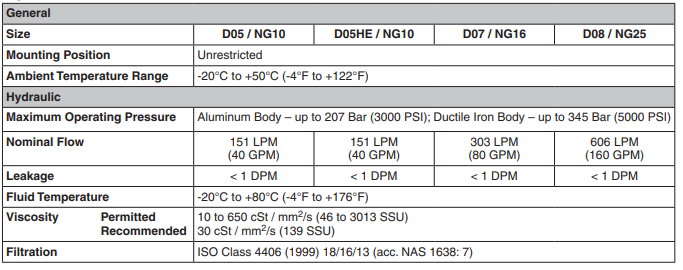

CP Specifications

ZRE Specifications

About the CPOM, CP, ZRE Series

Flow ratings, MAOP, mounting styles, cracking pressure, etc. depend on which size sandwich valve is chosen.

All specifications can be found in the catalogue linked adjacently.

CPOM Sizing Options

- CPOM2 - NFPA D03 / CETOP3 / NG6

- CPOM3 - NFPA D05 / CETOP5 / NG10

- CPOM4 - NFPA D07 / CETOP7 / NG16

- CPOM6 - NFPA D08 / CETOP8 / NG25

CP Sizing Options

- CP05 - NFPA D05 / NG10 / CETOP 5

- CP5H – NFPA D05HE / NG10 / CETOP 5H

- CP07 – NFPA D07 / NG16 / CETOP 7

- CP08 – NFPA D08 / NG25 / CETOP 8

ZRE Sizing Options

- ZRE01 – NFPA D03 / NG6 / CETOP 3

- ZRE02 – NFPA D05 / NG10 / CETOP 5