Engineered Materials Group

Composite Sealing Systems Division

Four Ways to Overcome Metal Sealing Challenges in Gas Turbines for Power Generation and Aerospace

Parker EMG has a reputation for innovative designs, high quality products, responsive support and customized solutions for unique and extreme environments. Our focus is on serving the fluid containment needs of high-technology industries that demand absolute integrity and reliability. With our extensive and integrated line of seals and sealing systems, we design, test, analyze and produce sealing solutions for a variety of extreme environments.

Making dependable sealing systems for safety-critical and extreme applications goes beyond excellence in design and manufacturing. It also means a deep commitment to understanding our customers’ challenges and developing solutions specifically tailored to their application. This commitment extends across all of Parker’s divisions, including our Composite Sealing System (CSS) Division which we spotlight in our webinar, High Performance Metal Seals: Improving Efficiency and Advancing Aviation and Power Generation Turbines.

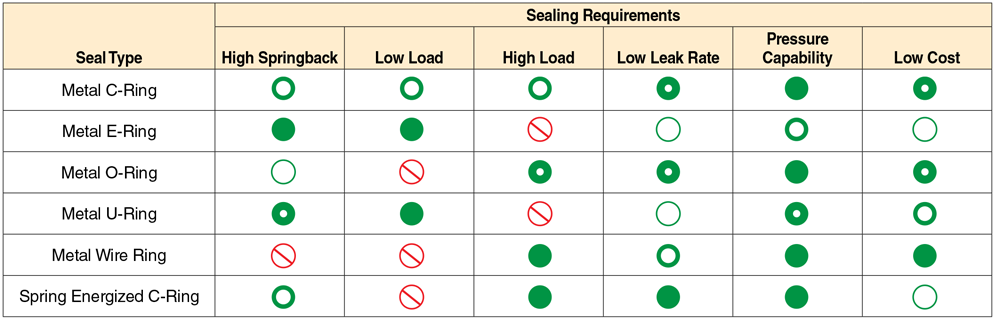

The Advanced Products Business Unit of Parker CSS Division focuses primarily on metal seals. These seals are used for critical applications with extreme temperature and extreme pressure. We have a wide variety of metal seal types, each with unique characteristics that we consider when designing for your application. These include:

- High spring-back

- High or low load

- Low leak rate

- Pressure capability

- Extreme temperature resilience

Figure 1. "At-A-Glance" Seal Type Comparison Table, Parker Catalog CSS5129, Pg. B-14

Two seals highlighted in the webinar include the spring-energized C-rings (great for high pressure and very low leakage) and E-rings (for very low load and high spring-back).

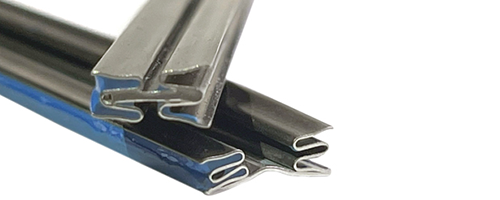

E-rings and C-rings, also referred to as E-seals and C-seals, are the most commonly used seals for gas turbines. Casing flanges and hot gas path turbine sections are the primary applications for E-rings in power generation engines. Casing seals, typically made of Inconel 718, are used to reduce flange leakage caused by thermal separation at these joints. They are shaped to follow the bolt pattern with caps applied at the seal ends to reduce leakage around those ends.

#1: Reduce Total Casing Costs with Casing E-ring Seals

Low load E-rings reduce the need for expensive casing bolts leading to significant cost-savings. Parker gas turbine customers are able to significantly reduce the total casing cost by utilizing our casing E-rings. They allow for the reduction of very expensive casing bolts, while preventing any additional leakage. These unique seals allow a substantial cost-savings compared to a traditional design with extensive casing bolts.

Figure 2. Casing E-ring seals (metal E-seals)

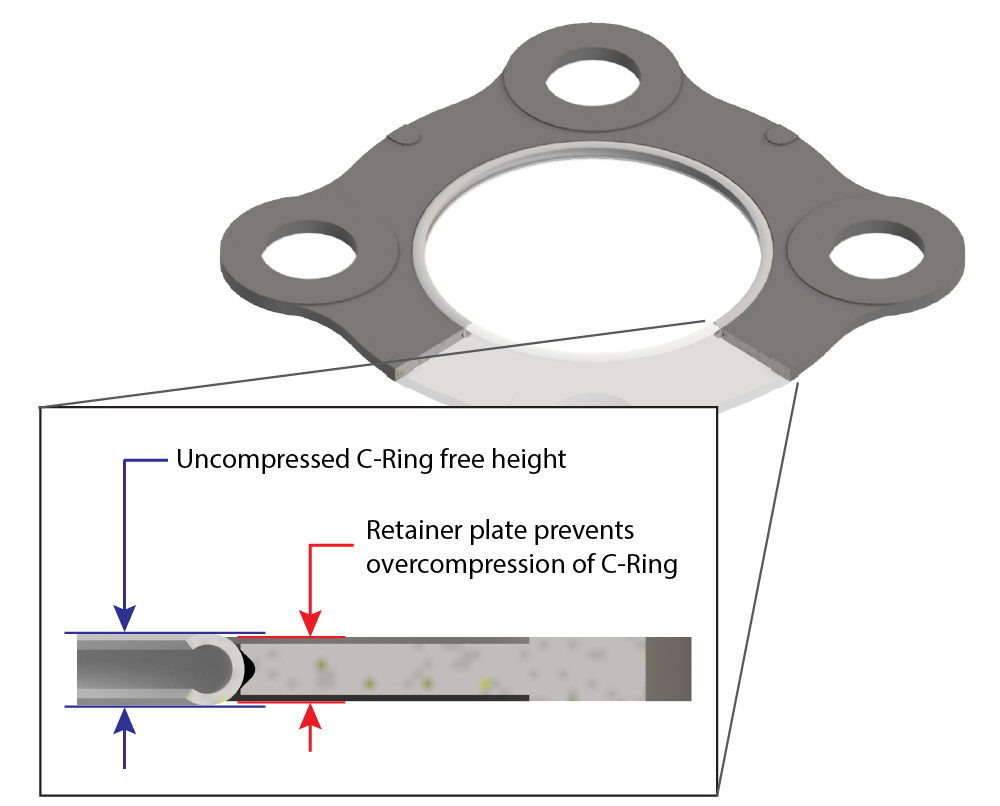

#2: Reduce Assembly Time and Eliminate Installation Damage

Turbine section seals are 360-degree seals that are often segmented into 90 or 180 degrees due to the large diameter size of the turbine sections. They are usually installed in closed cavities which can make installation very challenging. These section seals can be “pre-compressed” with an epoxy to an installation height that is smaller than the cavity depth, allowing for much easier installation. The epoxy will eventually break down when the turbine begins running and reaches operating temperature, allowing the seal to expand to the cavity and seal the joints. Parker's pre-compressed seals provide long-term savings, greatly reduce assembly time, and eliminate damage to new seals during installation.

Figure 3. Pre-compressed metal seal with connector band

#3: Eliminate Small Groove Machining Issues in Fuel Nozzle Assemblies

For power generation gas turbines, C-rings (or C-seals) are primarily used for higher pressure joint applications and fuel nozzles. C-rings don’t allow for as much variation as E-rings, but they provide reduced leak rates and high pressure capabilities. Spring-energized C-rings are also used occasionally for higher load, lower leakage applications.

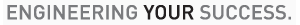

Figure 4. Spring-energized metal C-Ring

C-rings, along with spring-energized C-ring seals, are often used in fuel nozzle assemblies to seal at the flange area. Because aerospace engine fuel nozzles are smaller, and machining a groove is challenging, we typically use C-rings with limiter plates (a.k.a retainers). The retainer allows the seal to be used without a groove and limits the compression of the seal to protect against over-compression. In addition, the retainer has bolt holes so it can easily be assembled to the fuel nozzle flange. As an added benefit, the retainer is visible after installation to provide assurance of correct assembly.

Figure 5. Cross-section rendering of C-Ring with limiter plate

The MS33649-style fastener is another example of a C-ring application with a retainer. The C-ring is formed around a washer, creating a boss seal. The washer fits onto a fastener, centers the C-ring, and holds it in place. Boss seals can be used for a variety of threaded fasteners as long as the size is matched to the application

#4: Optimize Seal Material with Wear Protection

We have a variety of materials that can be used in different cross sections of our metal seals. Rene 41, Waspaloy and Inconel 718 are most commonly used for gas turbine engines. These materials are primarily chosen based on temperature with consideration of the mating hardware materials.

Parker metal seals can be manufactured bare, without a surface treatment, but they are most often plated or coated. The plating or coating is softer than the base material and fills the imperfections on the mating surfaces. Plating options we offer include indium, tin, PTFE, silver, gold, copper and nickel. Plating type is chosen based on your application’s specific requirements.

In applications with high vibration and large cavity movement, TriCom® coating is recommended as an anti-wear protection. TriCom® provides a smoother and more durable surface finish compared with the Industry standard T800 coating (a.k.a thermal spray). In addition, the wear surface finish provided by TriCom improves sealing effectiveness and reduces the leakage rate significantly. Tri-Com® is a cobalt chrome carbide and can be used up to 1,150 degrees Fahrenheit. There is also a TriCom-HT version for high temperatures, which is a cobalt nickel chrome carbide that can be used up to 1,400 degrees in continuous exposure.

Contact Us

If you would like to discuss metal sealing solutions or technical coatings for your application, please contact us at 800-C-Parker or through our website.

This article contributed to by Bret Sleicher, business development manager for Parker Composite Sealing Systems Division Advanced Products Business Unit.

Parker Hannifin Corporation

Engineered Materials Group

Composite Sealing Systems (CSS) Division

©2021 Parker Hannifin Corporation