Parker Hannifin

Motion Solutions for Laser Manufacturing

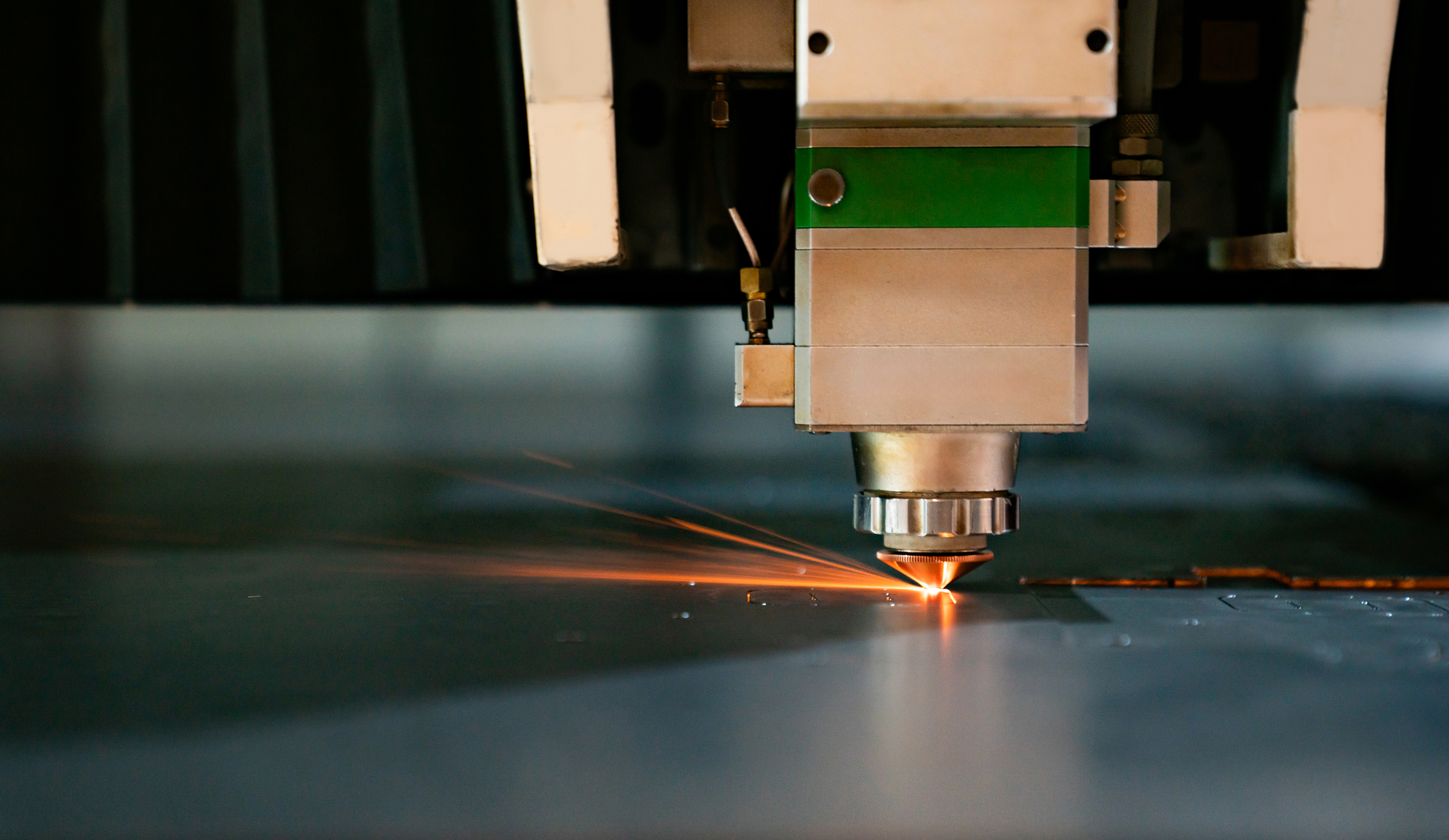

Laser manufacturing demands motion systems that can execute precise paths, maintain tight tolerances, and perform consistently across every cycle. Parker brings motion and control expertise to laser manufacturing applications, helping OEMs achieve smoother motion, higher accuracy, and predictable performance without compromising delivery timelines.

Why Motion Matters in Laser Manufacturing

Laser processing quality is directly tied to motion performance. Any vibration, inconsistency, or deviation in motion can affect cut quality, edge finish, and overall process reliability. As laser tools continue to advance, motion systems must deliver the same level of precision and repeatability as the laser itself.

Parker engineers motion solutions specifically to meet these challenges, supporting applications such as cutting, drilling, marking, and additive processes with stable, repeatable motion.

Parker Motion Solutions for Laser Tools

Parker’s portfolio of electromechanical motion solutions supports laser manufacturing OEMs across a wide range of tool architectures and performance requirements. From rigid linear stages to ultra-smooth ironless motors, our solutions are designed to integrate seamlessly into laser systems while delivering consistent performance from system to system.

By engaging Parker early in the design process, OEMs gain access to application expertise, system-level guidance, and proven motion technologies that help reduce development risk and accelerate time to market.

Laser Manufacturing Literature

Why Partner with Parker?

We deliver the same motion performance, system after system helping laser manufacturing OEMs reduce variability and bring tools to market with confidence.

Decades of motion

engineering experience

Manufacturing consistency

at scale

Full scale

distributor partnerships

Global support and

customization capability

For applications requiring exceptionally smooth motion, the XLM Series provides zero-cogging, ironless performance. This enables cleaner paths, tighter tolerances, and improved process consistency in laser manufacturing tools.

Delivers rigid, predictable motion designed to support precise laser paths and stable performance. Its compact footprint and manufacturing consistency make it well suited for laser tools where stiffness, accuracy, and repeatability are critical.

Deliver zero-cogging, vibration-free motion to support clean cuts, tight tolerances, and consistent energy delivery. The non-contact, ironless design minimizes disturbances, making I-Force ideal for laser cutting, marking, and micromachining applications.

Providing rigid, repeatable motion with excellent thermal stability. Designed to maintain accuracy under high duty cycles, RIPPED motors support fast positioning and stable laser paths, helping OEMs achieve consistent process results.

Contact Us

Have any questions? Fill out the form below and a Parker Representative will be in contact with you.