Engineered Materials Group

Engineered Polymer Systems Division

High Performance Resilon® Polyurethane Seal Material

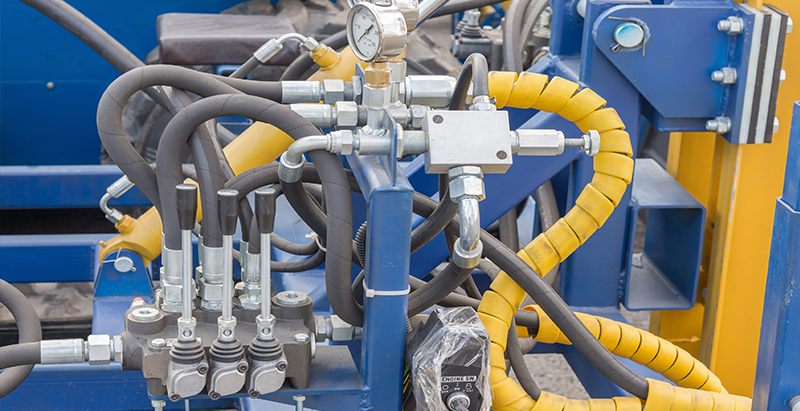

Thermoplastic polyurethanes (TPUs) have been an industry standard for dynamic sealing in hydraulic applications for the past 30+ years. Today, design engineers have an array of commercially available polyurethane materials – including Parker's Resilon® polyurethane seal material – to choose from depending on performance expectations and application requirements.

Characteristics shared by thermoplastic polyurethane seal materials make this class of material a leading choice for dynamic, high pressure fluid power applications. These characteristics include:

- High bond strength

- Wear resistance

- Thermal stability

- Hydrolytic stability

- Compression set resistance

- Resiliency

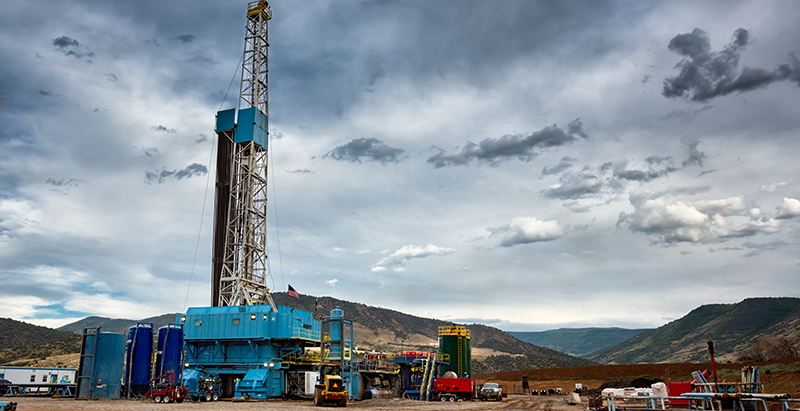

Learn how Resilon® polyurethane is improving performance and extending continuous operating time for:

Resilon® Polyurethane Material Formulations

Polymer Chemistry Differentiation

Thermoplastic polyurethane materials are prepared by reacting three basic components: diols or polymeric polyols, diisocyanates, and chain extenders. Different combinations of these ingredients yield TPUs customized for specific performance requirements. Most TPUs in use today are polymerized with one of three diisocyanates, each yielding different performance characteristics. Learn more about PPDI, MDI and TODI base formulations here.

Specific advantages of Parker Resilon formulations over conventional polyurethanes due to its PPDI-based polymer chemistry include excellent flex resistance, superior dynamic properties, and good cut and tear resistance at the temperature limits for polyurethane materials. We have Resilon polyurethanes that can operate at temperatures approaching 275°F (135°C) versus MDI-based compounds which are limited to around 212°F (100°C).

Resilon® 4300

| Typical Physical Properties | 4300A90 |

|---|---|

| Durometer (Hardness), Shore A, pts. | 90 |

| Modulus @ 100%, psi | 1674 |

| Ultimate Tensile Strength, psi | 8021 |

| Elongation, % | 638 |

| Rebound, % | 61 |

| Compression Set %, 70 hrs @ 212°F | 30.9 |

| Tg, DSC, °C | -41.6 |

| Temperature Range, °F | -65 to +275 |

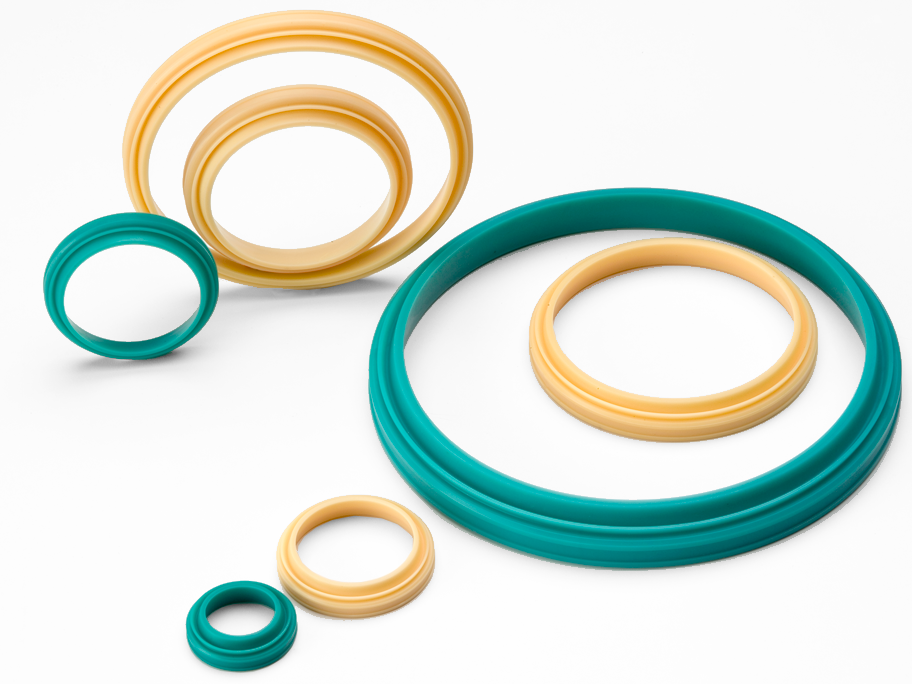

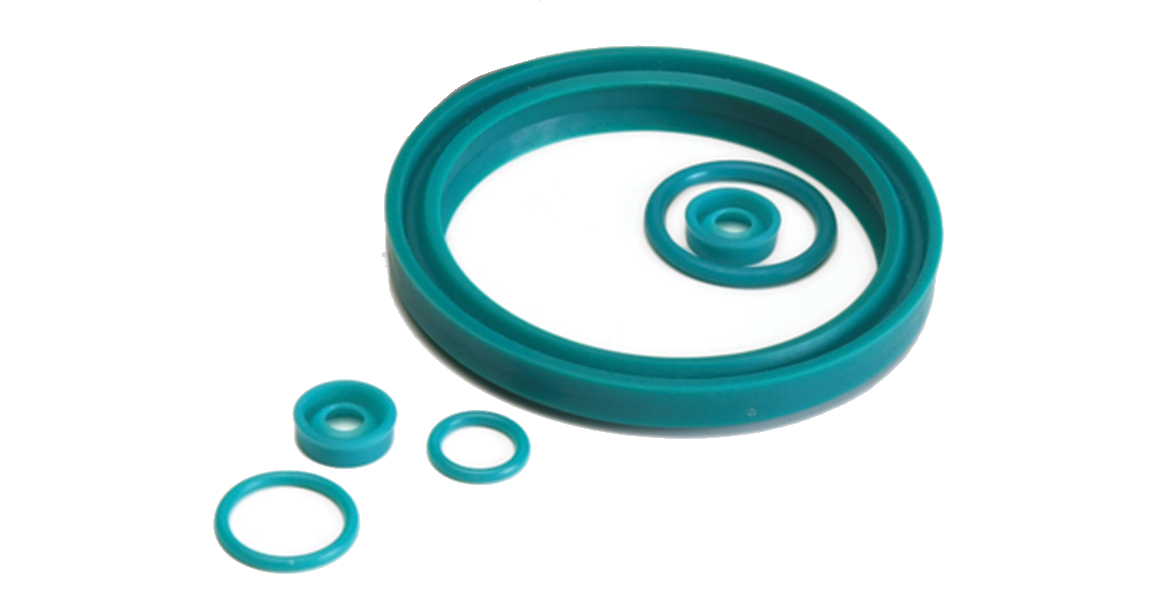

Applications: Recommended for piston seals, rod seals, wipers and O-rings for all types of light, medium and heavy-duty hydraulic cylinders, shock absorbers, seal products for oil and gas frac pumps, bellows & diaphragms, valves, bonded parts, and energy management applications such as polymer springs and bumpers.

Resilon® 4301

| Typical Physical Properties | 4301A90 |

|---|---|

| Durometer (Hardness), Shore A, pts. | 92 |

| Modulus @ 100%, psi | 1958 |

| Ultimate Tensile Strength, psi | 7188 |

| Elongation, % | 548 |

| Rebound, % | 41 |

| Compression Set %, 70 hrs @ 212°F | 36.5 |

| Tg, DSC, °C | -35.6 |

| Temperature Range, °F | -35 to +225 |

Applications: Recommended for piston seals, rod seals, wipers and O-rings for all types of light, medium and heavy-duty hydraulic cylinders, shock absorbers, valves, bellows & diaphragms, bonded parts, and energy management applications that require compatibility with water-based fluids.

Resilon® 4304

| Typical Physical Properties | 4304D60 |

|---|---|

| Durometer (Hardness), Shore D, pts. | 55 |

| Modulus @ 100%, psi | 2949 |

| Ultimate Tensile Strength, psi | 6896 |

| Elongation, % | 871 |

| Rebound, % | 46 |

| Compression Set %, 70 hrs @ 158°F | 38.7 |

| Tg, DSC, °C | -30.5 |

| Temperature Range, °F | -65 to +275 |

Applications: Recommended for piston seals, rod seals, wipers, well service packing, O-rings and anti-extrusion devices for all types of light, medium and heavy-duty hydraulic cylinders requiring higher extrusion resistance.

Resilon® 4350

| Typical Physical Properties | 4350A90 |

|---|---|

| Durometer (Hardness), Shore A, pts. | 90 |

| Modulus @ 100%, psi | 1870 |

| Ultimate Tensile Strength, psi | 8340 |

| Elongation, % | 570 |

| Rebound, % | 62 |

| Compression Set %, 70 hrs @ 212°F | 26.3 |

| Tg, DSC, °C | -44.1 |

| Temperature Range, °F | -65 to +300 |

Applications: Recommended for piston seals, rod seals, wipers and O-rings for all types of light, medium and heavy-duty hydraulic cylinders, shock absorbers, bellows & diaphragms, bonded parts, and energy management applications requiring continuous operating temperatures to 250°F and brief excursion temperatures to 300°F .

Material Selection

Material Selection

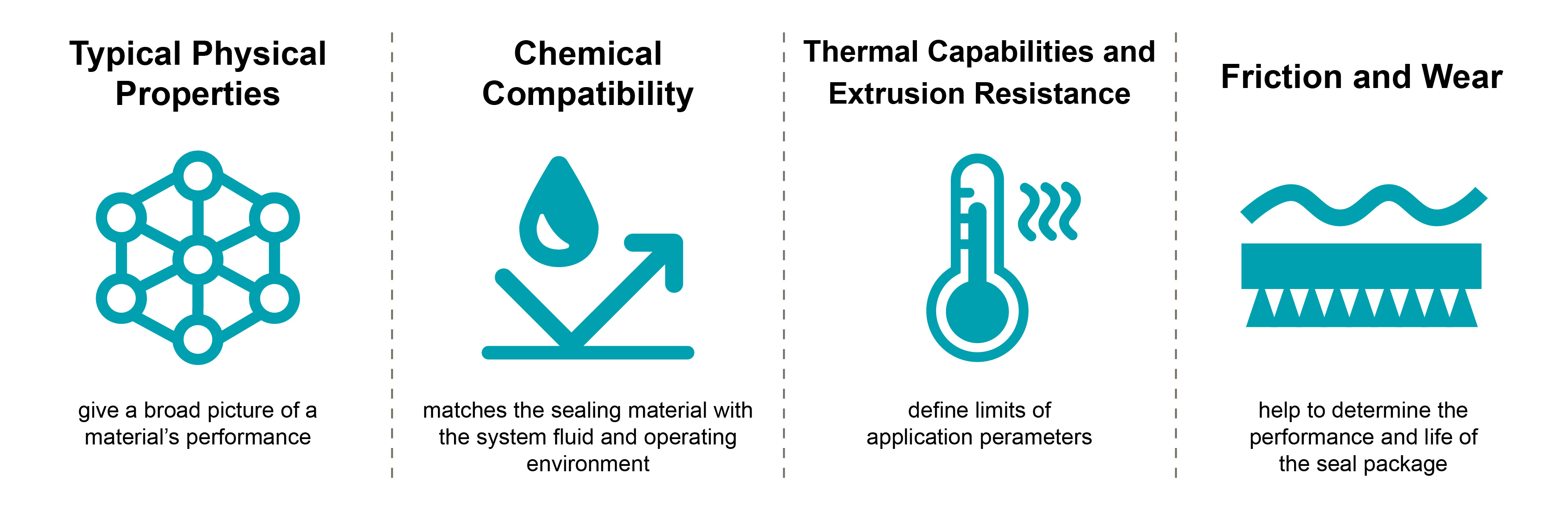

When selecting from the wide range of material options that Parker offers, there are several considerations to be made:

So how do designers go about selecting the optimal seal material for an application when there are so many to choose from? They consider all the variables. A useful resource for gathering and, if needed, conveying your specific critical application requirements is Parker's Design Action Request (DAR) form.

Need Assistance or Want to Learn More? We Can Help.

Material selection is a daunting task, for sure, but can be done in a systematic manner with guidance from the sealing and material experts at Parker.

- Step1: Download the Design Action Request form (DAR) and fill in the required information.

- Step 2: Contact us by submitting your information in the engineering request below.

Once we receive your request, an engineering associate will contact you to discuss your application. You can lessen time for response and evaluation by having the DAR filled out prior to contact since our engineers will need your specific application information from the Design Action Request form in order to provide assistance.

Contact us to discuss whether Resilon® materials may be suitable for your application.

Follow Step 1 above, then fill out the form below and an engineering associate will contact you.

©2022 Parker Hannifin Corporation

Engineered Polymer Systems Division

Ph: 800 233 3900

FOLLOW US