Roadheaders

Designed for Performance; Certified for Safety

Browse through our products that can be specified for roadheaders. Entries include technical specifications, support materials and where to buy details.

The new industry standard in high pressure hydraulic filtration incorporating advanced features designed to improve system reliability. Allowable operating pressure of 7000 PSI (483 Bar) and capable of flows to 137 GPM (520 LPM) depending on viscosity.

- 480 bar and 520 l/min

- Forged steel bowl

Parker GLF Series Low Pressure Return Line Hydraulic Filters combine high efficiency microglass filtration with low cost installation in a new patented element design. The filter element assembly is designed for direct mounting and can be easily removed for maintenance, providing customers with both convenience and dependability.

- Patented filter element

- Inside to outside filtration

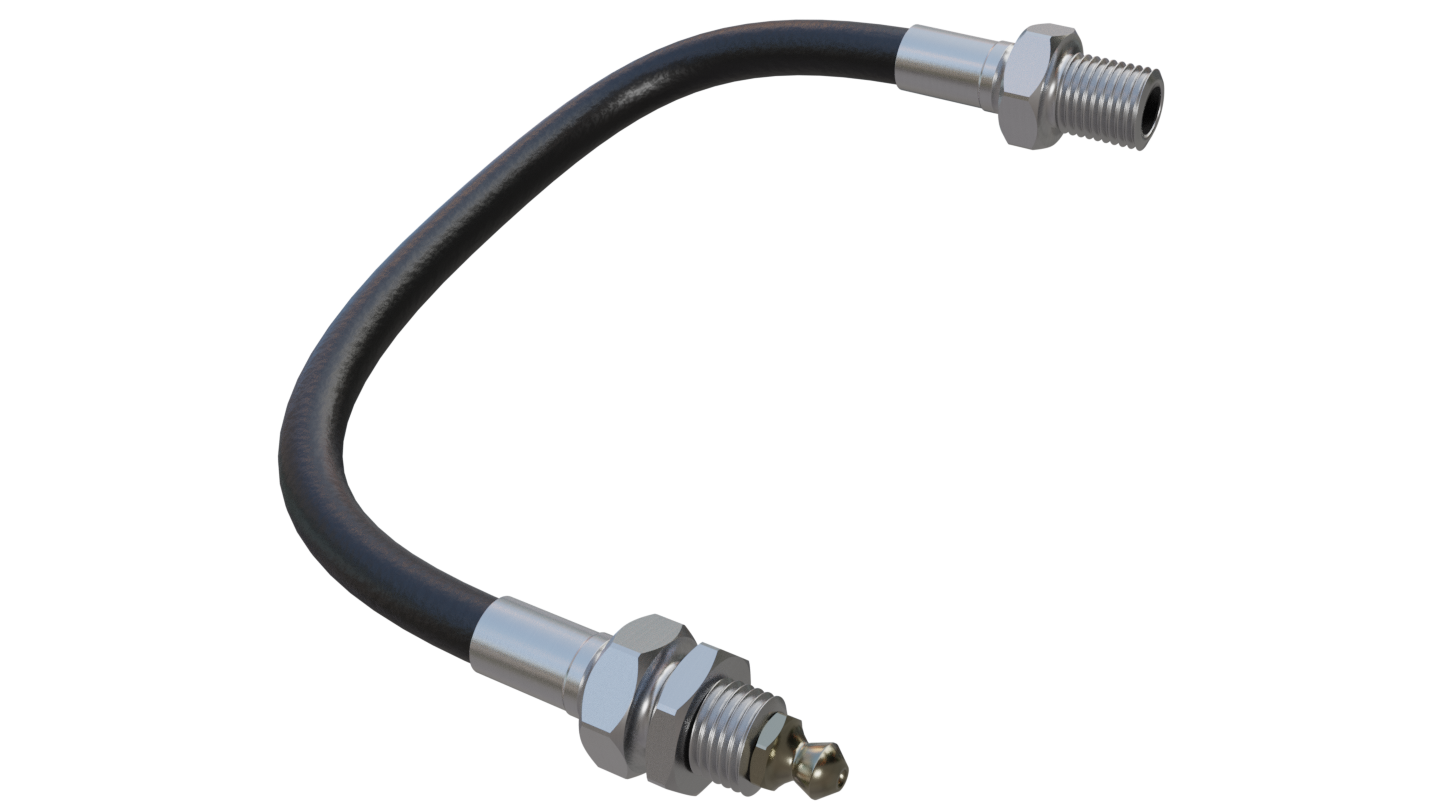

The Parker HLB Grease Hose is a cost effective solution that is MSHA accepted and is more compact than comparable rubber grease hoses. It is designed for grease and lubrication lines in agriculture, construction or mobile equipment.

- Pre-filled with grease

- Compact and flexible

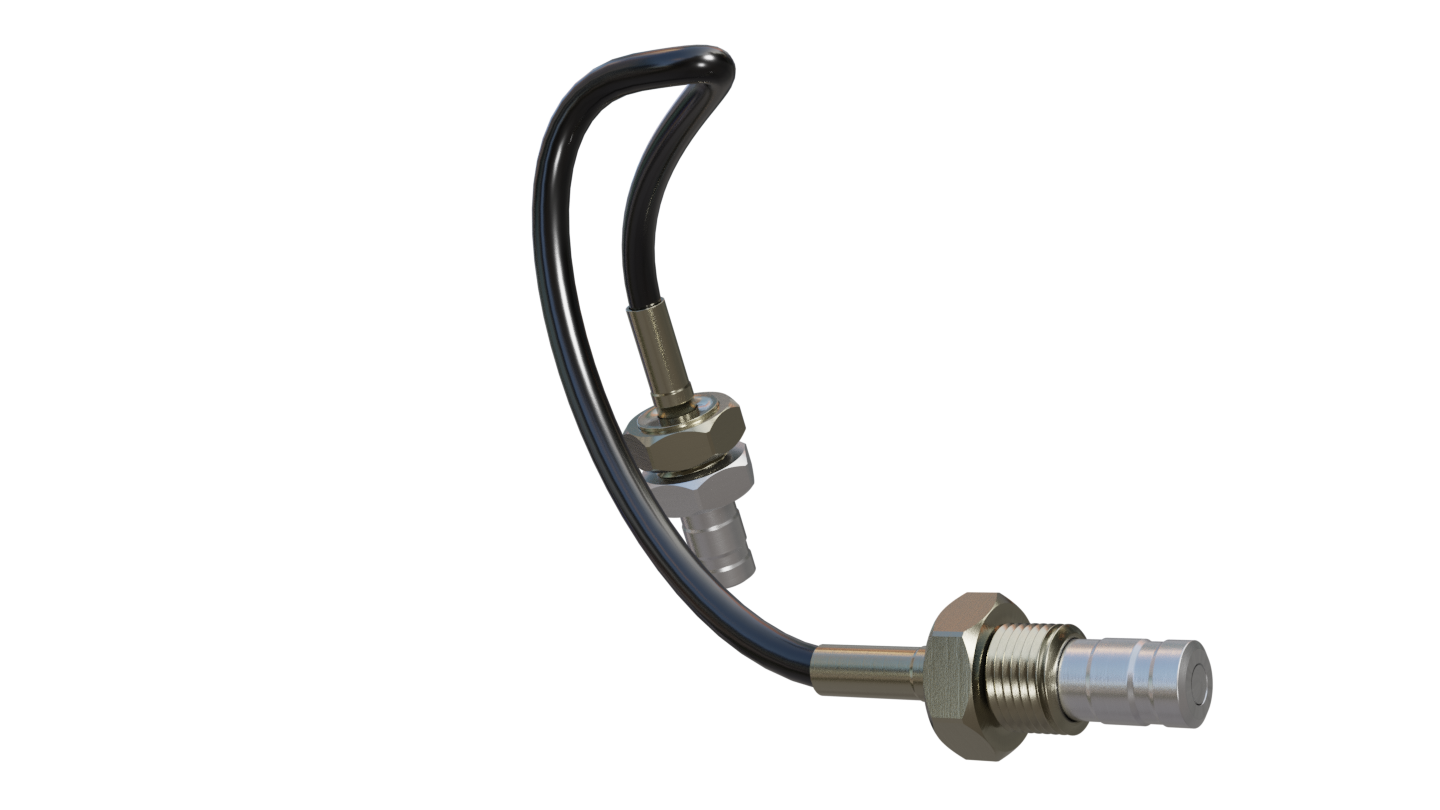

Parflex 56DH diagnostic hose offers the best in class performance by reducing the volume of fluid in the system over -4 rubber hose. This diagnostic hose has a compact O.D., making it the optimal solution for applications where a small diameter hose is desired.

- High pressure

- Fast and accurate response

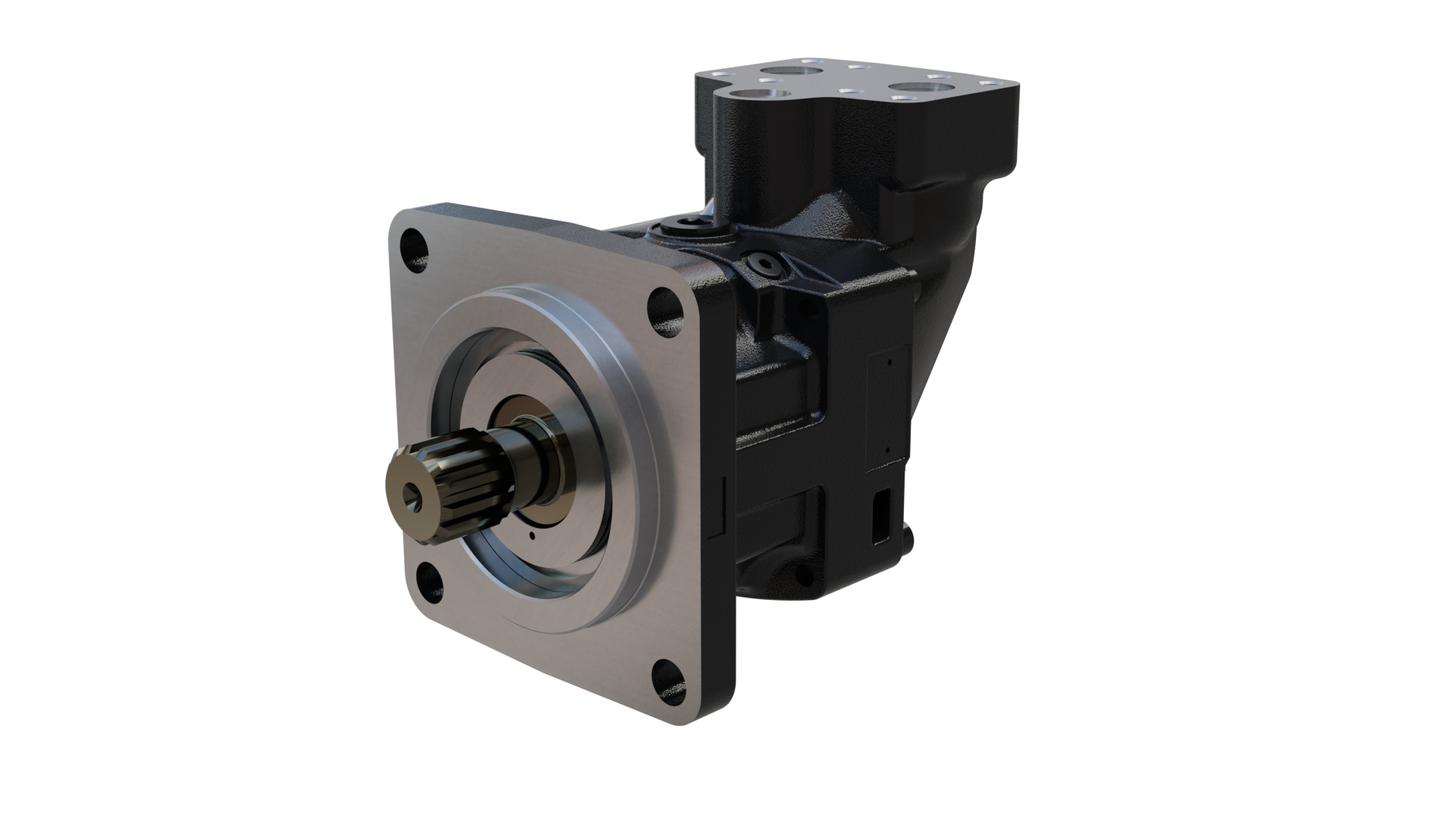

Parker F12 hydraulic motor series has operating pressures up to 480 bar (7,000 psi) and speeds up to 7.300 rpm. The F12 motor is a robust design motor, and can be used in numerous applications in both open and closed loop circuits. Sizes from 30-250cc.

- Speeds up to 7,300 rpm

- Highest efficiency

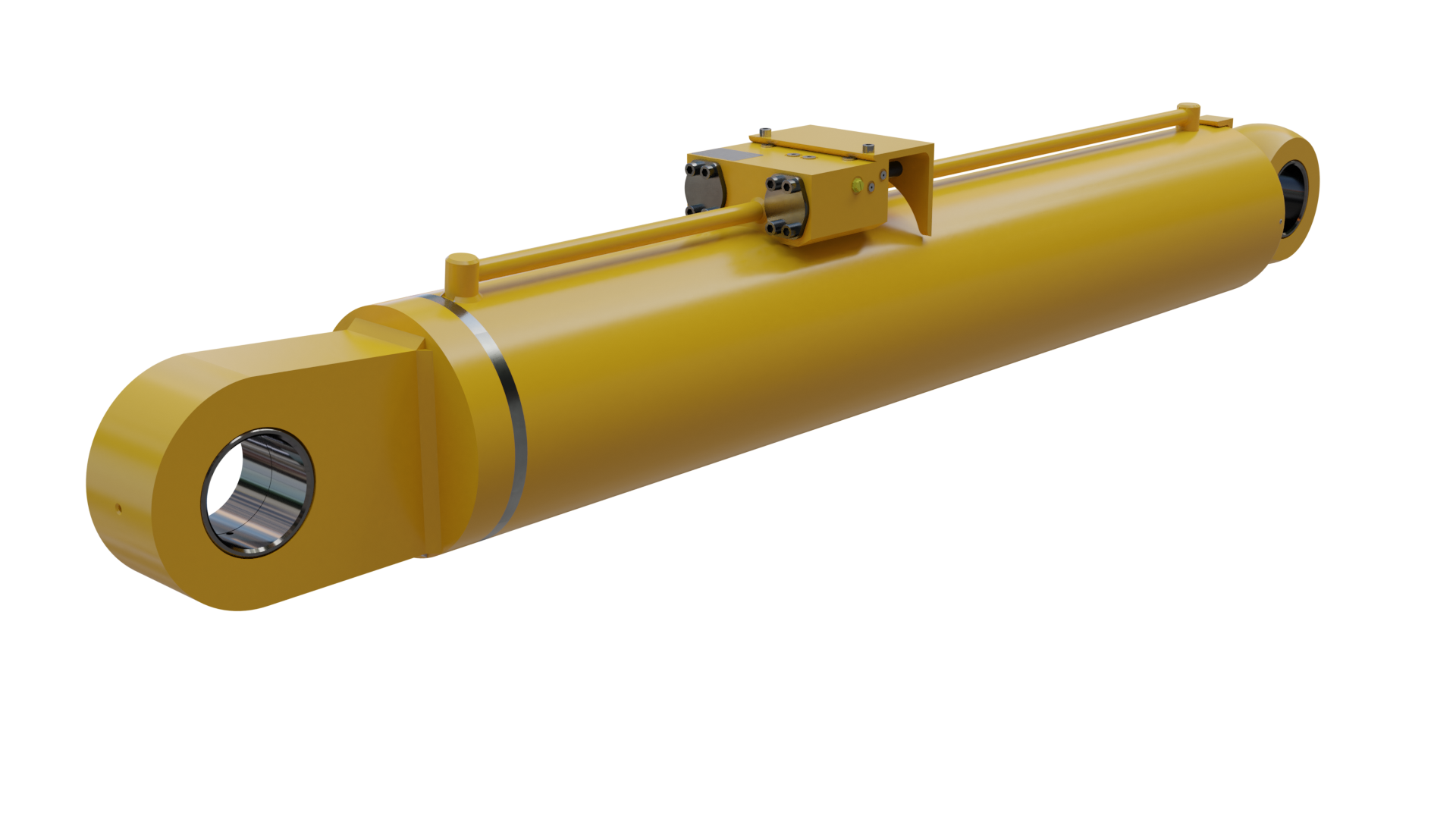

Series RDH industrial grade heavy duty roundline hydraulic cylinders provide extremely long cycle life and are field-repairable. 3,000 psi rated Series RDH is configurable in 9 standard mounts, strokes to suit your needs and many standard options.

- Engineered for long life

- Robust design

Parker's Press-In-Place Seals are custom designed seals that fit into complex groove patterns without needing to be stretched or retained. These custom seals are designed to withstand a wide variety of environments, fluids, pressures and temperatures.

- Seal retained in place

- Multiple design possibilities

Stand up to the ravages of red rust, Parker delivers the ultimate corrosion defense. Parker ToughShield Plating, up to 1,000 hours far exceeds the 72-hour SAE requirement. Parker XTR Coating offers more than 10x the 72-hr SAE requirement for corrosion resistance including urea exposure.

- Protection for highly corrosive environments

- Significantly more corrosion resistance than SAE standard

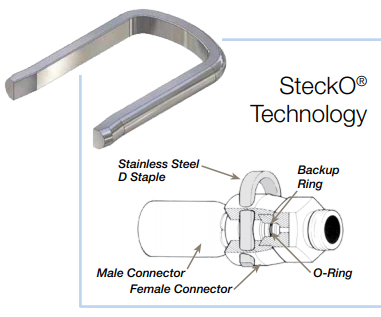

The original SteckO® staple connection system was introduced into the mining industry. The unique design enables the connection of hydraulic components, replacing threads or flange type fittings.

- MSHA certified

- Comprehensive product range

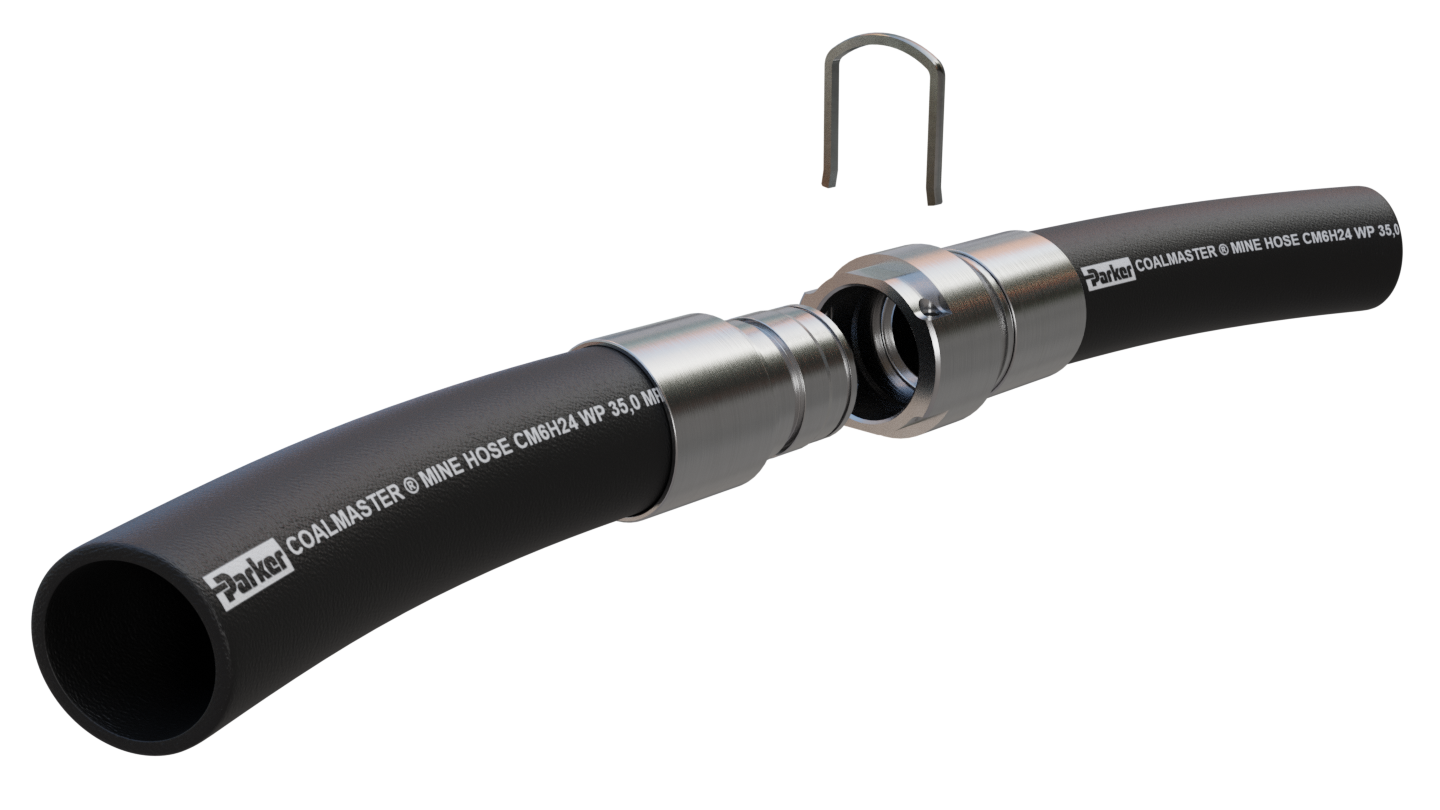

Mining is the primary application for Parker's COALMASTER hose. It features two braids of high tensile steel wire and a polyethelene abrasion resistant MSHA approved cover.

- Abrasion resistant

- Compact hose routing

Parker fuel/water separators provide a simple, economical and environmentally friendly method of removing water and other particulates. This provides maximum protection for diesel engine components in applications where reliability is absolutely critical.

- Easy system self-priming

- Eliminated messing filter pre-filling