파카하니핀 반도체 초고순도 피팅 밸브 솔루션

어렵고 까다로운 반도체 공정 설비를 생산할 때 무엇을 가장 우선으로 고려하시나요?

제품의 기능 및 안정성은 기본이며, 빠른 대응 또한 가능해야 합니다. 파카코리아는 제품의 국산화를 통해 고객의 필요에 누구보다도 빠르게 대응하고 있습니다.

파카코리아, Veriflo 제품 국산화 완료!

반도체 생산 공정은 웨이퍼 공정, 가공 공정, 테스티 및 조립 공정을 거치게 됩니다.

이러한 공정을 들여다 보면, 수 백개 이상의 복잡한 공정으로 이루어 지기 때문에 반도체 제조 장비를 생산하는 것은 매우 까다로운 일입니다.

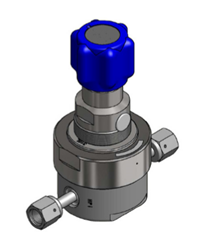

Parker Veriflo 의 SQ Series 레귤레이터는 가스 회사, 장비 제조업체 및 최종 사용자를 위한 프로세스 가스 캐비닛에 사용하도록 설계된 고 유량, 고성능 POS (Point-of-Use) 레귤레이터입니다.

SQ 시리즈 레귤레이터는 Tool Hook Up 공정에 적용하여 공정 가스 압력을 정밀하게 제어합니다. 그 결과, 질량 유량 제어기의 안정적인 유량과 압력이 유지됩니다.

파카코리아는 SQ140 레귤레이터를 비롯한 다양한 제품을 국산화하여 그 동안 해외 제조 제품을 사용하면서 불편을 겪었을 국내 장비 생산업체들에게 빠르게 대응하고 있습니다. 견적 기간 및 납기 단축으로 고객사로부터 큰 호응을 얻고 있습니다.

UHP 스테인레스 다이어프램 밸브(용접)

UHP Stainless Steel Diaphragm Valve Welded

830 / 930 Valve

• Parker Hannifin의 Veriflo 사업부의 태양열 및 반도체 응용 분야를 위한 830 밸브를 소개합니다. 830에는 930 시리즈 밸브 기능이 포함되어 있으며, 더 비용 효과적인 솔루션입니다.

• 수동 밸브의 최대 작동 압력은 300psig입니다. 또한 830은 LP(125psig) 및 새로운 MP(300psig) 공압 액추에이션 버전을 제공합니다.

[ Performance ]

* Design

• 검증 압력

AOPLP : 188 psig (13 barg)

AOPMP, L, I, M, S : 450 psig (31 barg)

• 파열 압력

AOPLP : 375 psig (26 barg)

AOPMP, L, I, M, S : 900 psig (62 barg)

* 유량 용량

• All AOP and Spin Handwheel

: Cv 0.30

• Lever (L), Mini Lever (M), Indicator Knob (I): Cv 0.22

UHP 스테인레스 퀵턴 핸들 다이어프램 밸브

UHP Stainless Steel Quick Turn Handle Diaphragm Valve

830QT Series

• Parker Hannifin Corporation의 Veriflo 사업부는 반도체 및 태양열 응용 분야를 위한 830 퀵 턴 핸들 밸브를 선보입니다.

• 퀵 턴 핸들 밸브의 최대 작동 압력은 150psig입니다.

• 잠금 장치를 실수로 켜고 끄는 것을 방지하는 동시에 잠금 및 해제 기능을 가능하게 하는 간단한 푸시 핀이 있어, 안전에 초점을 맞춥니다.

[ Parformance ]

* Design

• 검증 압력 : 225 psig (15.5 barg)

• 파열 압력 : 450 psig (31.0 barg)

• 유량 용량 : Cv 0.30

UHP 고순도 레귤레이터

UHP High Performance Point-Of-Use Regulator

SQ140E Regulator

SQ140E .5 Cv 초 고순도 감압 레귤레이터는 고유량 고압 가스 용도를 위해 특수 재료로 제작된 내부 나사 산이 없는 고정형 다이어프램을 제공합니다. SQ140E 는 프로세스 가스의 안정적인 압력과 다운스트림 시스 템의 안정적인 유량 성능을 제공합니다.

[ 성능 사양 ]

• 최대 입구 압력 • 250 psig (17 barg)

• 출구 압력 • 0 - 130 psig (9 barg)

• 파열 압력 • 750 psig (52 barg)

• 검증 압력 • 375 psig (26 barg)

• 유량 용량 • Cv = 0.5

• 내부 누출 • Under 4 x 10-8 scc/sec He

• 외부 누출 • 2 x 10-10 scc/sec He (인보드)

• 작동 온도 • -40°F ~ 150°F (-40°C ~ 66°C)

파카에 문의하세요.

영업 엔지니어가 해결해 드립니다.

UHP 스테인레스 스틸 다이어프램 밸브 - 고압, 고유량

UHP Stainless Steel Diaphragm Valve High Pressure, High Flow

17R / 18R Series

17R 시리즈 밸브는 고순도 유체 시스템을 위해 고유량 및 정극성 차단 기능을 제공합니다.

1/2" 스프링형 다이어프램 밸브는 진공에서 3,000psig까지의 압력 범위로 수동 및 공압 작동 버전에서 탁월한 누출 무결성 성능을 제공합니다.

[ Performance ]

* Flow Capacity

- Manual Cv 0.8

- Pneumatic Cv 0.75

* Leak Rate

- Design Internal

< 4 X 10-9 scc/sec He Inboard Test Method

- Design External

< 1 X 10-9 scc/sec He Inboard Test Method

* Production Leak Test

Outboard sniffer probe at 2000 - 2500 psig, 20-25% Helium

체크 밸브 - CV1

본딩 체크 밸브 - CV3

Check Valve - CV1

Check Valve, Bonded - CV-3

CV-1 and CV-3 valves

벌크 화학 시스템은 점점 더 큰 직경의 배관/튜브 시스템을 요구하고 있습니다. Parker는 오늘날 업계에서 가장 큰 형광고분자 체크 밸브를 제공합니다.

체크 밸브는 금속이 없으며 모든 새로운 고순도 형광 중합체로 만들어져 거의 모든 화학 물질에 이상적입니다. 독특한 디자인은 매우 낮은 균열 압력, 높은 흐름 및 높은 무결성 씰링을 제공하여 역류 보호를 제공합니다.

[ Features ]

• Low cracking pressure

• Low back check sealing pressure

• Parbond ends are removable for welding

• High purity, made from virgin PTFE

• Compact size

UHP 싱글 스테이지, 압력 레귤레이터 내부 나사산 없음

UHP Single Stage, Pressure Regulator Internally Threadless

QR4000 & NPR4000 Series

QR4000은 고정되지 않은 고순도 다이어프램 레귤레이터 입니다. 메탈-to-메탈 다이프램 씰을 사용하여 누출 무결성을 향상 시킵니다.

NPR4000 조절기는 저압 가스원의 음의 공급 압력과 관련된 용도에 사용됩니다. 일반적인 용도에는 WF6, BCL3과 같은 액체 공급원으로부터의 저압 가스 전달이 포함됩니다.

[ Performance ]

* Flow Capacity

- Cv Options : Cv 0.06 (std), Cv 0.02, Cv 0.15

* Leak Rate : Inboard Test Method

- Internal < 4 x 10-8 scc/sec He

- External < 2 x 10-10 scc/sec He

* Supply Pressure Effect : Based upon Cv Option

• QR4000

0.02 Cv : 0.23 psig/100 psig (0.16 barg/7 barg)

0.06 Cv : 0.6 psig/100 psig (0.04 barg/7 barg)

0.15 Cv 1.5 psig/100 psig (0.1 barg/7 barg)

UHP 스테인레스 다이어프램 밸브 - 고압, 용접

UHP Stainless Steel Diaphragm Valve High Pressure, Welded

845 / 945 Valve

945 밸브는 반도체 공정 제어를 위해 특별히 설계되었으며 내부 볼륨과 차체 크기를 줄이면서 944 시리즈의 모든 기능과 장점을 갖추고 있습니다.

945의 독특한 특징은 튜브 스터브에 가공되어 치수 제어를 개선할 수 있다는 것입니다.

[ Performance ]

* Design

• Proof Pressure

AOPHP, I, L, M, S : 5,250 psig (362 barg)

G : 188 psig (13 barg)

• Burst Pressure

AOPHP, I, L, M, S : 10,500 psig (724 barg)

G : 375 psig (26 barg)

* Flow Capacity

AOP, G, S, I Cv 0.25 Lever Cv 0.18

스팀레스 컨볼루티드 PTFE 호스(Nomex 브레이드 포함)

Seamless Convoluted PTFE Hose (with Nomex Braid)

Parker Polyflex PTFE Hoses

Parker PTFE 호스는 PTFE의 고유한 특성으로 인해 다양한 시장 및 애플리케이션에 완전한 이송 솔루션을 제공합니다.

[ Unique properties of PTFE ]

• Inert to virtually all chemicals

• Applicable from -70 °C up to +232 °C (depending on hose type)

• Minimizes pressure drop and deposits on hose inner surface, easy to clean

• Convoluted designs have excellent bend radius properties

• Low tendency to hydrolysis

• Unlimited shelf life of bulk hose

실리콘 PTFE 호스(정전기 소산 튜브 포함)

Silicon Covered PTFE Hose

(with Static-Dissipative Tube)

919BJ Static-Dissipative PTFE Hose with Silicone Cover

비전도성 유체를 위한 정전기 소산 코어 튜브를 사용한 실리콘 보호 와이어 보강재 입니다

[ Features ]

• Static-dissipative core tube minimizes the generation of static

. • Silicone cover provides a clean, smooth cover to protect the internal hose components against wear, fraying, and contaminants

• Silicone cover provides increased safety to operators by significantly reducing the outer cover surface temperature of the hose when conveying high temperature media

• Resists moisture

• Excellent chemical compatibility

소형, 논스필 스테인리스 퀵 커플링

Compact, Non-Spill Stainless Steel Quick Couplings

NSS Series

응용 프로그램이 유체 손실 또는 공기 유입으로 인해 품질 또는 안전 문제가 크게 발생할 수 있는 중요한 프로세스 환경과 관련된 경우 Parker의 NSS Series 비스필 커플링을 통해 안전한 연결을 제공합니다. 부식 방지, 매체 호환 재료로 구성된 NSS 퀵 커플링은 다음을 수행하도록 설계되었습니다.

[ Features ]

• Non-spill valving ensures minimal fluid loss and low air inclusion

• Easy push to connect operation with guided alignment

• High flow and compact size

• Stainless steel construction

• Seal material and end fitting options

간단한 푸시-풀 동작 커플링

Simple Push-pull action Instrumentation Couplings

CPI Series

간단한 푸시-풀 동작으로 라인을 연결하고 분리할 수 있으므로 도구가 필요하지 않습니다.

. • 진공 또는 압력 시스템을 위한 안정적이고 누출 방지 O-링 씰입니다.

. • 커플러와 니플은 밸브형 또는 비밸브를 사용할 수 있습니다. 밸브는 연결 시 자동으로 열리고 분리 시 차단되어 액체나 가스 손실을 최소화합니다.

• 양극 밸브 스톱은 유량 점검을 방해합니다.

. • 밸브 가이드가 밸브와 시트를 확실하게 정렬하여 누출을 방지합니다.

[ Specifications ]

Vacuum Rating : Parker CPI Series will handle vacuums up to 50 millitorr or .05 mm of Hg absolute pressure.

파카 솔루션 영상 보기

Parker Veriflo QR4000

How to Reduce Consumable Costs in Semiconductor Fabrication Process - Sealing Solutions

파카하니핀 코리아에 직접 문의하세요.

온라인 전시 및 일반 문의