Why Select Parker Tubing ?

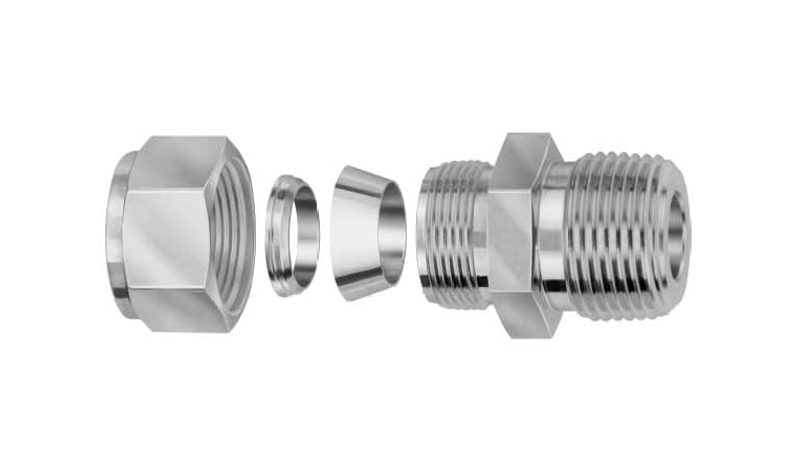

When designing a leak-free instrumentation system, one of the first steps to ensuring safety and reliability is to select the right tubing for the intended application. Parker’s instrument tube fittings have been designed to work in a wide variety of applications that demand the utmost in product performance.

Increasingly, process control instrumentation solutions are being applied in ever more hostile environments.

Corrosion is a major challenge for many design engineers and specifiers in the general industrial market. Choosing the right materials is critical to ensure optimal performance, as even the highest quality products can fail if not used properly.

Engineers must carefully analyse the proposed operating environment when selecting materials for industrial applications. Answering three important questions will help unearth potential problems and provide useful guidance on appropriate materials to use.

Q1. Is the material composition susceptible to cracking?

Q2. Is the application environment potentially corrosive?

Q3. Is the material concentrated load under tensile stress?

You will find some basic guidelines based on our extensive knowledge and experience in applications worldwide. Download the whitepaper to find out "Smarter Materials Selection for Corrosion Control" for your particular application.

Download the

Whitepaper Now!

Simply fill out the form below and click submit.

Read more from Parker Process Control

Proper tube selection and installation, we believe, are key ingredients in building leak-free reliable tubing systems. This article is intended to assist the designer to properly select and order quality tubing.

Parker Instrument Tube Fittings are designed to be used for process control and instrumentation connections between Tube and pipe sizes.