INDUSTRY

DEFENSE

PRODUCTS USED

TECHNOLOGY

CONDUCTIVE PAINTS

CONDUCTIVE SEALANTS

CONDUCTIVE ELASTOMERS

CASE STUDY

EMI Shielding and Weather Sealing Solutions for Armored Vehicles

A global defense contractor is tasked with developing the next generation of armored land fighting vehicles, each needing to provide first-class protection and survivability, reliability and all-weather performance.

Armored vehicles are now being designed and developed with IoMT (Internet of Military Things) in mind, compassing a large range off intelligent sensing, learning, and actuation capabilities through virtual or cyber interfaces that are integrated into the vehicle’s systems.

EMI Shielding and Sealing Challenges

All on board electronics need to work efficiently and reliably, but due to the complexity of the operating systems and the volume of electronics inside the vehicle, electromagnetic interference (EMI) is a large issue for the customer.

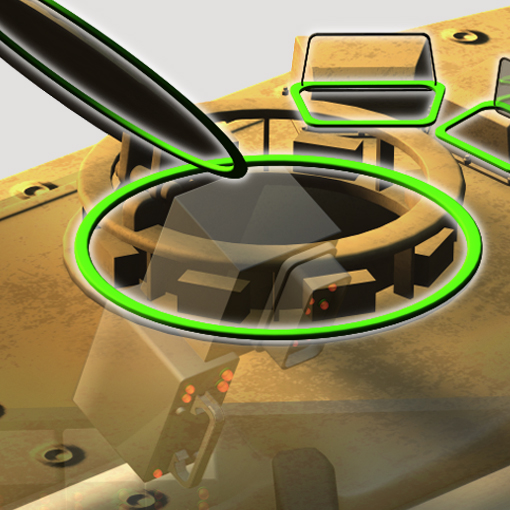

Both an EMI solution and environmental weather sealing is required around the ingress and egress hatches to prevent rainwater/fluid from entering the vehicle.

Multiple optical periscope cameras and sensors on the vehicle required EMI/RFI shielding to ensure reliability. All air intake and exhaust ducts required EMI shielded ventilation panels to allow for airflow but shield extraneous RF waves.

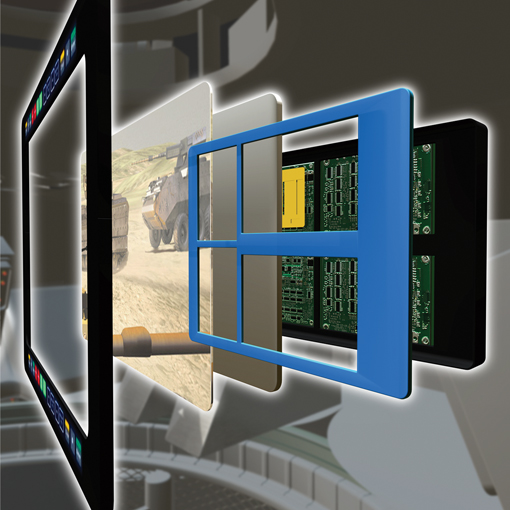

EMI shielding around touch screen display.

MIL-STD Design Requirements for EMI Shielding

The armored fighting vehicle needed to become essentially an armored Faraday cage to protect the internal electronics to ensure their smooth and reliable operation in the battlefield. We've written extensively about EMI shielding technology necessary for defense applications on our blog.

EMI shielding materials need to meet rigorous military standards (MIL-STD) and are subject to stringent EMI testing. EMI/RFI signature from the vehicle needs to be reduced to prevent the vehicle being picked up by enemy tracking systems.

Key Program Requirements

Both EMI shielding and corrosion resistant materials are required. Materials should be resistant to harsh fluids, including chemical washdown.

Each armored fighting vehicle needs to be ‘future-proofed’ to ensure it can be upgraded quickly and effectively throughout its service.

Electrically conductive elastomer gaskets around hatch seals and doors.

Parker Chomerics Developed EMI Shielding Solution

To provide an effective EMI and environmental seal to ingress and egress hatches, the following materials are being designed into the application.

Parker Chomerics application engineers, in partnership with the customer’s design team, determined that CHO-SHIELD 2002, an electrically conductive polyurethane coating with a copper conductive filler would help to aid in corrosion resistance. This material is specifically formulated to offer corrosion protection for enclosure flanges which mate with EMI shielding gaskets. It also offers excellent chemical resistance to hydraulic fluids and motor oils.

To help fill seams in gaps and around rivets, a silver-plated aluminum filled silicone electrically conductive sealant called CHO-BOND 1075 was used to give additional EMI protection and to provide an adhesive bond for the gasket.

A robust dual gasket configuration, called a co-extrusion, made from CHO-SEAL 1298 material, containing both a silver-aluminum filled electrically conductive silicone gasket alongside a non-conductive military grade environmental gasket was also chosen. This gasket was positioned around the entrance hatches to ensure compliance with both EMI and environmental requirements.

In other applications on the vehicle, CHO-SEAL 1298 EMI shielding gaskets were custom made for use with multiple periscopes cameras. Several connector gaskets were also fabricated out of CHO-SEAL 1298 material and were used to shield electronic hardware.

All air intake and exhaust ducts required circular steel EMI honeycomb vents, fitted to allow air flow while providing an EMI shield.

The Parker Chomerics applications engineering team worked closely with the customer design team to meet rigorous testing procedures and ensure compliance of all specified technologies.

Armored personnel type carrier

Get Your Free Samples of EMI Shielding Products

We offer a comprehensive range of EMI shielding solutions to meet a variety of project requirements, from cost-effective options to highly robust and durable solutions. Whatever your specific needs may be, you can count on us to provide you with the most suitable EMI shielding solutions to ensure optimal performance and reliability.

EMI Shielding Technology Applications in Defense Systems

As the defense industry continues to push the boundaries on advanced electronic systems and state-of-the-art communication devices, the requirements governing these programs must follow suit. Among the many technical requirements is Electromagnetic Compatibility, defined as the ability of a device to withstand both anticipated and unanticipated electronic interference (EMI) as well as minimize the interference being radiated.

Solutions for Aerospace & Defense

The engineers at Parker Chomerics are experts in creating EMI shielding, electrically conductive materials and corrosion resistance for military and aerospace applications. Aerospace OEMs and MROs trust us to deliver cutting-edge solutions that increase sustainability, reliability and efficiency for the lifecycle of the aircraft, including aftermarket support.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

Empowering Your Business on a Global Scale

Parker Chomerics’ manufacturing operations span the globe, allowing us to serve you locally no matter where you are. We understand your unique needs and provide personalized solutions that cater to your specific requirements.

Can't find what you're looking for? Talk to one of our experts.