Case Study

Resolving Transmission Housing Leakage in Agriculture Equipment Exposed to Weather & Low Temperatures

Application

Customer supplies a hydraulic transmission assembly, primarily used in agricultural equipment, to multiple customers. The transmissions experiences temperatures that range from -15 °F to 250 °F with the fluid reaching a maximum of 50 psi. Due to the nature of the equipment this housing is subject to outdoor storage and exposure to natural elements, including rain and sub-freezing temperatures.

FEATURED PRODUCT: Integral™ Seal for Hydraulic Transmission

Challenge

End user has observed leaks in the hydraulic assemblies located at the bottom cover gasket interface. Current sealing method utilizes a solid nitrile shape compressed between the transmission housing and the bottom cover plate which creates problems including:

- Gasket is compressed between housing and cover by torquing 10 self tapping screws to 100-120 in/lb.

- Without the aid of a compression limiter, the gasket experiences over-compression leading to loss of original shape.

- Solid nitrile bottom cover gasket is not distributing sealing pressure evenly across gasket housing interface.

- Misaligned holes between the gasket and transmission housing caused the rubber to fray during installation.

Misalignment problem

Parker Solution

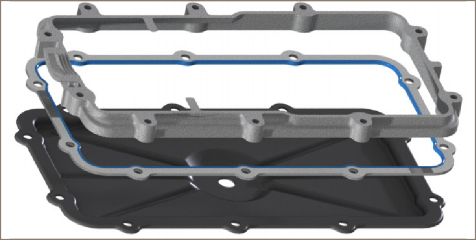

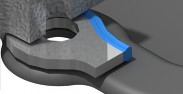

Parker engineered a customized rubber-to-metal bonded Integral Seal™ gasket comprised of a rigid aluminum retainer with an edge-bonded, vulcanized fluorocarbon (FKM) sealing element.

The thermal expansion properties of the aluminum matches that of the mating hardware.

The rigid retainer frame serves as a compression limiter to prevent over compression during installation which can cause the sealing element to lose elasticity and sealing force.

A Fuji impression of the new design confirms an even distribution of sealing contact pressure against the mating hardware (in contrast to the incumbent solution).

Using a repeatable metal stamping process we are able to provide consistent bolt hole locations within .008” on our retainers and eliminate misalignment during installation.

Parker solution

Fuji impression of new design

Contact

Parker Hannifin

Composite Sealing Systems Division

7664 Panasonic Way

San Diego, CA 92154

(619) 661-7000

www.parker.com/css

NEED ENGINEERING ASSISTANCE?