Case Study

Avionics cover installation and seal retention challenge solved by redesigning and engineering bonded one-piece enclosure which incorporates features that simplify install and eliminate assembly costs.

Application

In the avionics Industry, fixed and rotary wing aircraft use radar altimeters (also called radio altimeters) to determine the altitude or aircraft height above the terrain. Altimeters typically consist of a receiver-transmitter, antennas, and an indicator. They are connected to a warning system that informs the pilot if the aircraft is flying too low or descending too quickly. Protecting sensitive aerospace instruments is critical. Due to the nature of the aircraft this housing is subject to vibration and low temperatures.

FEATURED PRODUCT: Customized one-piece enclosure with bonded Gask-O-Seal®

Challenge

An aerospace electronics customer approached Parker CSS for assistance resolving a seal retention problem for a radar altimeter. The incumbent design used an O-ring in a groove located in the base of the altimeter. Problems experienced with the design included:

- In order to install and properly seat the O-ring into its groove, it needed to be stretched and stressed in multiple directions.

- Once installed into the groove, the seal tended to roll or stretch out of the groove due to the tight fitting force required as the altimeter cover slid over the base.

Application Example

Parker Solution

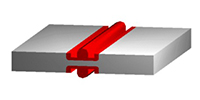

Parker designed a customized Mark I bonded Gask-O-Seal® in the instrumentation housing cover rather than in the housing's based to create a one-piece, permanently bonded seal in place.

Utilizing elastomers approved for use in aerospace sealing, the seal is molded directly into the retainer groove on the flattened enclosure substrate. The enclosure was then metal formed and bent to its final cover shape.

Working with the customer, Parker engineers utilized FEA modeling to determine the optimal bonded elastomer cross section so as to assure its bent fit maintained proper seal compression and sealing force.

Added value customization. In the course of working on the design, the CSS design team identified an opportunity to enhance utility of the enclosure by molding in rubber pushbuttons on the top of the cover.

Our design engineering of this customized single piece solution for the customer saved installation cost and assembly time by eliminating the need for screws which had been used to attach the push buttons. The customer was so pleased with the final design they are incorporating the rubber-to-metal bonded Gask-O-Seal® and molded-in-place buttons into additional radar altimeter products.

Gask-O-Seal®

Flat state, interior view

Contact

Parker Hannifin

Composite Sealing Systems Division

7664 Panasonic Way

San Diego, CA 92154

(619) 661-7000

www.parker.com/css

NEED ENGINEERING ASSISTANCE?