Safeguarding Alternative Energy with Engineering Innovation

April 3, 2023

Around the world, businesses and consumers alike are turning their attention to alternative energy sources such as solar, wind and hydropower. These eco-friendly options provide a number of attractive benefits, including the opportunity to:

- Reduce carbon emissions.

- Stabilize energy costs instead of constantly adjusting to fluctuating oil prices.

- Improve an organization’s reputation while demonstrating corporate social responsibility.

This growing interest isn’t just hype; it’s backed by large investments in green, sustainable energy, and many companies are hard at work developing a broad suite of innovative products to meet the demand.

However, for all their promise, these alternative energy sources share some common challenges that must be considered to safely reap the benefits, particularly in regards to storage. As energy sources do their job and produce large amounts of energy, they also produce heat, which can lead to equipment malfunctions and fire hazards if not properly controlled. Thermal products such as gap filler pads and thermal gels are essential to manage the heat and keep the products performing correctly. Here are a few common use cases we see in alternative energy today.

Residential and Commercial battery energy storage systems (BESS)

If electricity will not be used immediately after it’s created, a Battery Energy Storage System (ESS) often becomes necessary. This advanced green technology utilizes battery chemistry (such as lithium-ion, nickel-cadmium, lead-acid, or nickel metal hydride) to capture and store energy generated from alternative energy sources and is particularly valuable in cases where electricity is generated in large quantities at varying time frames, such as with wind energy. Additionally, a BESS plays a valuable role for homes or businesses who want to have a backup power source as a buffer in case of blackouts or inclement weather, or sell power back into the grid. With a BESS in place, businesses and homes will have a continual power flow regardless of these external circumstances. Storage batteries are popular solutions, charging as excess power is available then discharging as demand increases. However, without proper precautions and materials, batteries can become hot enough to cause a fire or cease to function properly due to overheating.

2nd generation batteries in electric vehicles (EVs)

Electric vehicles (EVs) are powered by electric engines instead of internal combustion engines, eliminating the need for gas and oil within these cars. These are very attractive to consumers and businesses alike, as companies like Amazon are leading the way in incorporating EVs into their delivery fleet. Similar to BESS, extreme precision and care must be utilized when manufacturing EV batteries, particularly the 2nd generation ones that are even more powerful. Despite their high-performance and exposure to harsh conditions – such as warm climates or bumpy roads – the batteries must continue to function properly and not overheat. Additionally, modern EVs are generally equipped with Advanced Driver Assistance Systems (ADAS) such as backup cameras and lane-change technology that play a vital role in protecting lives. These systems contain high-performance, critical electronics that run off of the vehicle batteries while also producing heat of their own.

Stacking power needs

The larger a company’s commitment to alternative energy, the larger their power storage needs become. Consider a big box retail store, which may be powering its own operations with solar panels or other energy sources while also supplying charging stations for its customers and employees. A backup power source called a load bank may be used in this scenario, which distributes power as needed throughout the local grid. These compact, efficient load banks are attractive options, as they offer favorable capital and operating costs while reliably storing power. In addition to the large amounts of heat generated within them, load banks are subjected to temperature fluctuations and must function properly regardless. Otherwise, businesses risk a major outage that could come with both economic repercussions and disgruntled customers.

Solutions that keep alternative energy products performing

To help them produce reliable alternative energy sources that will withstand these challenges, customers from a wide variety of industries trust Parker Chomerics to provide effective and reliable thermal interface solutions.

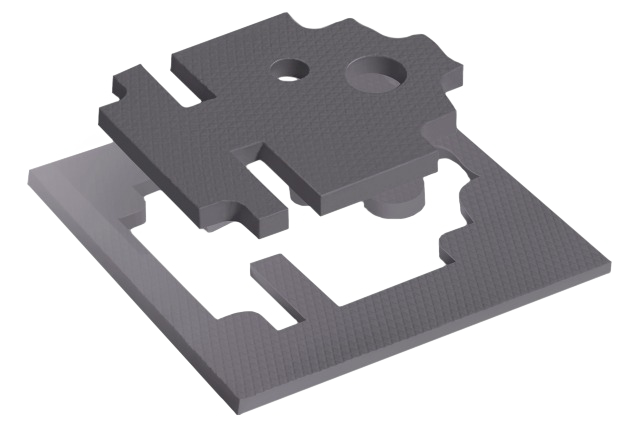

Our thermal interface materials transfer heat from electronic components to heat sinks and are used to eliminate air gaps from the interface. They are also highly reliable and will enhance an application's handling ease and performance, guaranteeing a longer service life. Our thermal interface materials – including thermally conductive gels and pads – have been designed into thousands of applications, ensuring high performance and integrity.

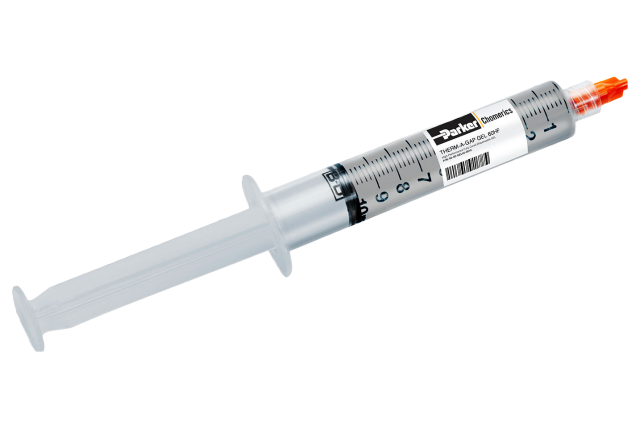

THERM-A-GAP™ GELs are single-component dispensable thermal gap fillers that require no curing and can be dispensed over a heat-generating component for effective cooling. THERM-A-GAP GELs eliminate multiple thermal gap filler pad part sizes, and their cross-linked gel structure provides superior long-term thermal stability and performance.

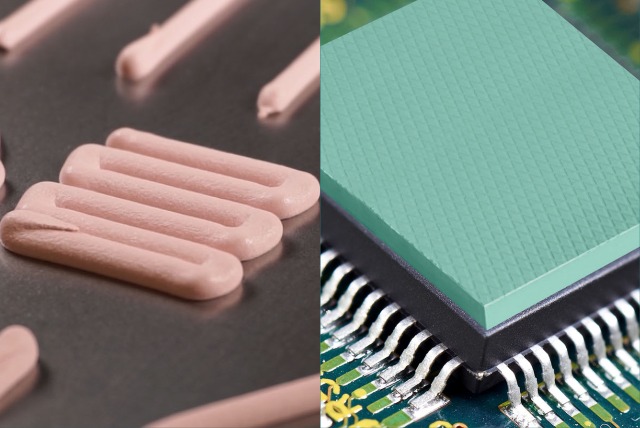

THERM-A-GAP™ gap filler pads are a family of low hardness, thermally conductive silicone elastomers for applications where heat must be conducted over a large and variant gap to a heat dissipating surface.

With reliable thermal interface materials in place, alternative energy sources can safely live up to their potential and helps businesses and consumers alike enjoy a greener future.

Sarah Kuhn

Marketing Communications Manager

Parker Chomerics

THERM-A-GAP PAD 80

Parker Chomerics THERM-A-GAP™ PAD 80 Thermally Conductive Gap Filler Pads provide a low hardness (35 Shore 00) solution with 8.3 W/m-K of thermal conductivity.

THERM-A-GAP GEL 60HF

THERM-A-GAP GEL 60HF is part of the Parker Chomerics family of fully cured, one component, silicone-based, dispensable thermal interface materials. With a 6.2 W/m-K thermal conductivity, it is designed for high performance heat transfer from electronics components to cooling features and meant to be used across industries and applications. Learn more.

PROVEN PERFORMANCE

The leader in Thermally Conductive Interface Materials.

We continue to advance technologies to bring new and enhanced capabilities and efficiencies.

Improve Assembly Efficiency with THERM-A-GAP™ GEL 60HF

In manufacturing production facilities, every fraction of a section counts. Parts must be made and assembled quickly and correctly to meet customer demand and stay ahead of the competition. To address this need and give our customers a competitive advantage, we’re proud to introduce THERM-A-GAP™ GEL 60HF.

This Is the Next Generation High Performing Thermal Gap Filler Pad

Looking for high thermal conductivity, yet ultra-soft thermal gap filler pad? Then you’ll want to take a close look at THERM-A-GAP PAD 60, which offers the enticing combination of both excellent thermal conductivity at 6.0 W/m-K, at a softness of 31 Shore 00. This makes THERM-A-GAP PAD 60 more than 40% softer than current-like-performance thermal gap pads from Parker Chomerics.

Read the blog →

Non-Silicone Dispensable Thermal Gel for Automotive Infotainment and Camera Modules

While “electrification” and “EV” buzzwords have taken center stage in conversations about vehicle electronics, drivers of all vehicle types as well as passengers and pedestrians are the beneficiaries of advanced safety, navigation, and entertainment systems.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.