Best New Fluid and Corrosion Resistant Electrically Conductive Sealants

March 23, 2023

The next-generation family of fluid and corrosion resistant electrically conductive sealants are here. Polythioether based conductive sealants and gap fillers are proven to be a reliable and a worthy addition to the Parker Chomerics CHO-BOND® family of conductive sealants and adhesives.

Two filler packages to choose from

- CHO-BOND 1018, a new, nickel-aluminum filled, electrically conductive polythioether sealant, is ideally mated against an aluminum substrate. Galvanically compatible with silver-aluminum filled electrically conductive elastomer gaskets such as CHO-SEAL 6502 or CHO-SEAL 6503.

- CHO-BOND 1019, a silver-aluminum filled electrically conductive polythioether sealant, which is ideally mated against an aluminum substrate. Galvanically compatible with silver-aluminum filled electrically conductive elastomer gaskets such as CHO-SEAL 1298 or CHO-SEAL 1285.

Why electrically conductive sealants and gap fillers?

Electrically conductive sealants, also known as electrically conductive gap fillers, or electrically conductive caulks, are designed to seal the seams and gaps of electronics enclosures, while providing excellent electrical conductivity, grounding and EMI/RFI shielding.

For decades, electrically conductive sealants have been designed using silicone or polyurethane based polymers, and then impregnated with a variety of conductive particles to achieve electrical conductivity.

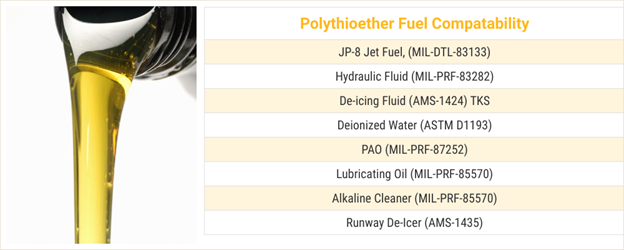

Polythioether offers excellent fluid and fuels compatibility

Engineers have taken notice of the benefits of polythioether, used for its excellent resistance to water and corrosion, aggressive chemicals, aircraft fluids (jet fuels, deicer fluids, hydraulic fluid and PAO based coolants).

Electrically conductive sealants made from polythioether binders are ideal for applications exposed to harsh environments such as on aircraft, UAVs, guided munitions, avionics, radar installations, military shelters, or other unforgiving applications.

Nickel-aluminum and silver-aluminum conductive filler technology

Polythioether can then be impregnated with a variety of different electrically conductive metallic particles depending on the galvanic compatibility requirement of electrically conductive sealant.

Remember your galvanic compatibility corrosion guide to dissimilar metals from grade school? Electrically conductive sealants must be galvanically compatible both with the electrically conductive gasket they are mated with as well as the flange or substrate of the equipment itself.

More stable EMI shielding performance & conductivity compared to nickel-fillers

Both CHO-BOND 1018 and CHO-BOND 1019 offer better EMI shielding performance, and more stable electrical conductivity versus other nickel-filled polythioether sealants on the market today.

After salt fog chamber testing using test specs ASTM B117 and CHO-TM100, a competitor’s nickel-filled polythioether had a 10x increase in volume resistivity while CHO-BOND 1018 only increased 6x and CHO-BOND 1019 had no increase. An increase in volume resistivity means a decrease in electrical conductivity.

From 300 MHz to 40 GHz, the competitor nickel-filled polythioether had nearly a 30% reduction in EMI shielding effectiveness over the frequency range compared to only a 10% drop for CHO-BOND 1018 after a 500-hour salt fog exposure tested to ASTM B117 and IEEE 299.

Extend field life, lower maintenance costs

Without the galvanic compatibility of like metals, increased corrosion, decreased field life, and increased maintenance costs are likely.

Both CHO-BOND 1018 and CHO-BOND 1019 are galvanically compatible to aluminum substrates, however CHO-BOND 1019 is better for applications where high conductivity or electrical grounding is required.

Both CHO-BOND 1018 and CHO-BOND 1019 are designed to be easily dispensed via hand or pneumatic tools, and applied to panel joints, seams, or other small clearances. Often, they must act as a barrier against the common causes of galvanic corrosion on aluminum alloys or between dissimilar metals.

Preventing galvanic corrosion

CHO-BOND 1018 is filled with nickel-aluminum particles, making the material ideal for corrosion resistance and galvanic compatibility with aluminum.

CHO-BOND 1018 is galvanically compatible with Parker Chomerics CHO-SEAL 6502 nickel-plated aluminum filled silicone and CHO-SEAL 6503 nickel-plated aluminum filled fluorosilcone gaskets.

Figure 1. CHO-BOND 1018 Before 1000 Hour Salt Fog

Figure 2. CHO-BOND 1018 After 1000 Hour Salt Fog

CHO-BOND 1019 is filled with silver-aluminum particles, making the material ideal for corrosion resistance and galvanic compatibility with aluminum. CHO-BOND 1019 is galvanically compatible with Parker Chomerics CHO-SEAL 1298 silver-aluminum filled silicone or CHO-SEAL 1285 silver-aluminum filled fluorosilicone gaskets.

Silicone-free – no contamination or fisheyes!

While many electrically conductive sealants have a silicone binder, polythioether is ideal for applications sensitive to silicone contamination.

There are no concerns with silicone leaching or causing issues with electronic assemblies or fiber optic cables.

Easily paintable with less steps

Being silicone free, polythioether is also easily paintable, requiring no advanced priming or sealing, which helps to reduce installation costs and time.

The adhesion of MIL-PRF-23377 TYPE II Class N and MIL-DTL-53022 TYPE II epoxy primers have been qualified for both CHO-BOND polythioethers.

Excellent EMI shielding performance

Both CHO-BOND 1018 and CHO-BOND 1019 offer excellent EMI shielding capabilities, offering an excellent 200 MHz to 40 GHz, even after exposure to a 1000-hour salt fog and thermal cycling.

Get a sample of CHO-BOND 1018 or CHO-BOND 1019 now and start testing. Our team of experienced application engineers are ready to help you make the best selection for your program and design parameters, so reach out to us today.

Brian Flaherty

Product Line Manager, Special Materials

Parker Chomerics

CHO-BOND 1018

Get a sample of CHO-BOND 1018 or CHO-BOND 1019 now and start testing. Our team of experienced application engineers are ready to help you make the best selection for your program and design parameters, so reach out to us today.

PROVEN PERFORMANCE

The leader in EMI shielding materials.

We continue to advance technologies to bring new and enhanced capabilities and efficiencies.

EMI Shielding and Weather Sealing Solutions for Armored Vehicles

A global defense contractor is tasked with developing the next generation of armored land fighting vehicles, each needing to provide first-class protection and survivability, reliability and all-weather performance. Armored vehicles are now being designed and developed with IoMT (Internet of Military Things) in mind, compassing a large range off intelligent sensing, learning, and actuation capabilities through virtual or cyber interfaces that are integrated into the vehicle’s systems.

How to Prevent Galvanic Corrosion

What is galvanic corrosion? How can you prevent it in your electronics systems using electrically conductive materials?

Learn about what corrosion is and the factors that create it so you can help to avoid it.

How to Test and Validate Electrically Conductive Sealants and Adhesives

Testing and validating for your program requirements are important ways to confirm electrically conductive adhesive and sealant material conformance to industry specifications. Transfer impedance, volume resistivity and shielding effectiveness testing are common standardized testing done at Parker Chomerics. Learn more about why these testing and validation procedures are important to your design and application.

INNOVATION FOR THE FUTURE

The products you need to stand up to harsh environments.

Parker Chomerics CHO-BOND 1018 is a nickel-aluminum filled, two-component electrically conductive polythioether designed for use as a fillet, gap filler and seam sealant on electrical enclosures for EMI shielding.

Parker Chomerics CHO-BOND 1019 is a silver-plated aluminum filled, two-component electrically conductive polythioether designed for use as a fillet, gap filler and seam sealant on electrical enclosures for EMI shielding.

Parker Chomerics CHO-SHIELD® electromagnetic interference shielding coating is specially formulated to provide premium performace.