THERM-A-GAP GEL 50TBL: The Next Generation of Thin Bond Line Thermal Interface Materials

September 26, 2023

Miniaturization. Higher Power. Higher Component Density. These are the trademarks of many modern electronic devices. While these trends are helping push the boundaries of what devices can do, they come with their fair share of challenges. Most notable of these challenges is the long-term reliability of electronics associated with a controlled operating temperature range. Thermal Interface materials (TIMs) are improving in lock step with modern electronics but must get more efficient and be able to operate in smaller gaps. THERM-A-GAP GEL 50TBL (TBL = Thin Bond Line) is the Parker Chomerics solution to thin bond line applications and an alternative to current greases and phase change materials (PCMs).

NOTE: As referred to in this article, thin bond lines are characterized in the range of 50 microns (0.05mm) or 0.002 inches.

Benefits of Thin Bond Lines

- Enhanced thermal performance: thin bond line TIMs provide lower thermal resistance

- Conformability: thin bond line TIMs are often more conformable and able to reduce air gaps

- Space saving: thin bond line TIMs can provide heat transfer between tight tolerance surfaces

- Improved reliability: thin bond line TIMs allow for improved reliability due to efficient heat transfer

Ideal Applications for Thin Bond Line TIMs:

- High-performance computing – CPUs, GPUs, entire server assemblies

- Telecommunications – routers, switches, 5G infrastructure

- Automotive electronics – engine control units, power modules, ADAS components

- Power electronics – inverters, converters, rectifiers, power supplies, power optimizers

- LEDs – industrial lighting, commercial LEDs

Issues with Current Thin Bond Line Solutions

Current solutions for thin bond line thermal interface materials include greases and phase change materials. And while both are used globally in applications across industries, they both have drawbacks and limitation.

Greases:

- Pump out – due to the microscopic expansion and contraction of materials as a result of temperature fluctuations, some greases are known to have issues with pump out where the material is slowly “pumped” out of a gap. This results in inconsistent contact and therefore limited heat transfer

- Hardening or cracking – over time, greases may harden or become brittle and crack which can cause decreased performance and component failures

- Difficult to rework – once greases harden, they can be very difficult to clean up or rework and may require solvents or cleaning agents.

Phase Change Materials (PCMs)

- Burn in cycle – PCMs need to go through a burn in cycle to “melt” the material and displace any air trapped in the gaps of electronics assemblies. This usually requires applying force to the PCM, running the chips for a certain period of time, and then reapplying a compressive force in order to make sure there is effective surface contact

- Difficult to rework – PCMs can be difficult to rework after operation and after they have been thermally cycled

- Limited automated assembly options – most PCMs cannot be applied using automated or robotic systems and may require manual application

- Temperature range limits – most PCMs have an upper operating temperature range of 125°C, limiting their use in high temperature applications

THERM-A-GAP GEL 50TBL

THERM-A-GAP GEL 50TBL is a 5.0 W/m-K, fully cured, one component, thermal gel that was developed as an optimal solution for thin bond line applications and an improvement to the performance limitations of traditional materials such as greases and phase change materials.

THERM-A-GAP GEL 50TBL Material Properties:

- No pump out – like all Chomerics thermal gels, it will not exhibit a pump out effect

- No hardening or cracking – designed to maintain physical characteristic for long product life with no hardening

- Easy to rework – formulated for ease of clean up and reapplication

- No burn in cycle – fully cured material that can be used from the moment it is applied

- Automated assembly options – can be packaged in large containers (up to 1 gal. pail) for automated, robotic dispensing

- Wide temperature range – has an operating temperature range from -55°C to 200°C

Bonus Thermal Performance:

While GEL 50TBL has a bulk thermal conductivity of 5.0 W/m-K as measured using the ASTM D5470 test method, at minimum bond line (50 microns, 0.05mm, 0.002”) it will exhibit an apparent thermal conductivity of 10.0 W/m-K. With its excellent ability to “wet out” and minimize contact resistance, GEL 50TBL will perform as well as materials with twice its bulk thermal conductivity properties.

With its unique thermal and mechanical properties, Parker Chomerics THERM-A-GAP GEL 50TBL is the newest, high-performance product for thin bond line applications.

Ben Nudelman

Global Market Manager

Parker Chomerics

THERM-A-GAP

GEL 50TBL

Parker Chomerics THERM-A-GAP GEL 50TBL is a reworkable, high performance, one component, dispensable, thermal interface material with 5.0 W/m-K Bulk Thermal Conductivity.

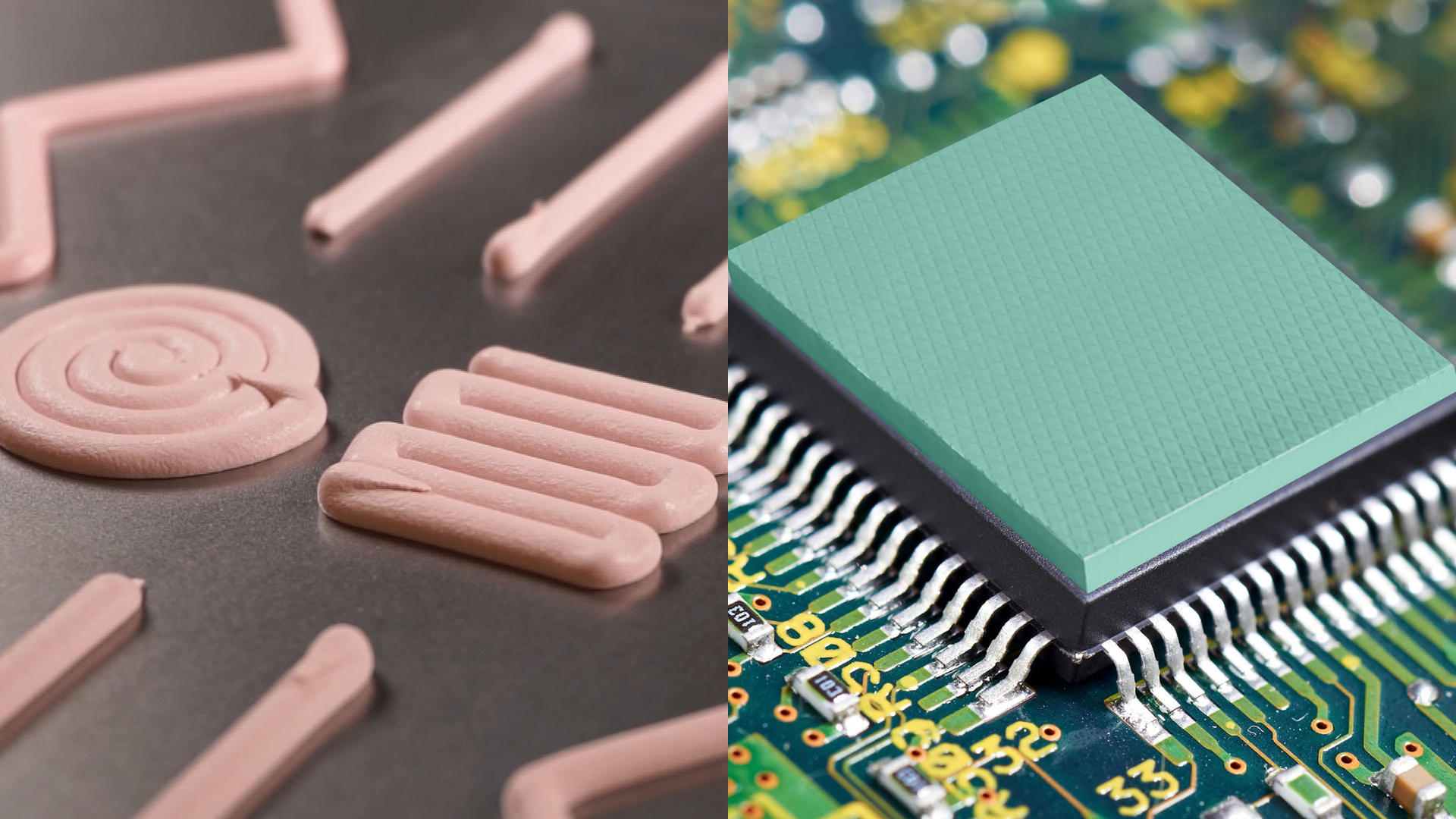

Solutions for Thermal Interface Materials

Parker Chomerics thermal interface materials transfer heat from electronic components to heat sinks and are used to eliminate air gaps from the interface. Our THERM-A-GAP® materials deliver lower thermal impedance, higher thermal conductivity and greater compliance and conformability to both microelectronics and large scale electronics.

Quality & Reliability that Ensure the Utmost Satisfaction

Our parts are designed and manufactured to perform precisely as advertised, meeting and exceeding all necessary specifications.

Solving EV Charging Station Design Challenges: Thermal Interface Materials and EMI Shielding Solutions

Electric vehicle (EV) battery charging stations, also known as EV charging stations or EVSE (Electric Vehicle Supply Equipment), consist of various electronic components and systems that work together to safely and efficiently charge the batteries of electric vehicles. Like most modern, high power electronics, these devices must overcome challenges associate with thermal management and electromagnetic interference (EMI) shielding in order to operate properly and effectively.

Non-Silicone Dispensable Thermal Gel for Automotive Infotainment and Camera Modules

Automotive electronics designers and engineers have been working with component suppliers to push the boundaries of material properties used to maintain long term reliability of these AVNT and Infotainment systems. The basis for long term reliability has been higher performance processors and chips, leading to secondary design concerns. Electronic modules have to be electrically shielded to prevent interference from nearby modules and also cooled to prevent overheating, a leading cause of electronic device failure. In the case of safety features, device failure is not an option.

Safeguarding Alternative Energy with Engineering Innovation

Around the world, businesses and consumers alike are turning their attention to alternative energy sources such as solar, wind and hydropower.

This growing interest isn’t just hype; it’s backed by large investments in green, sustainable energy, and many companies are hard at work developing a broad suite of innovative products to meet the demand.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.