When Reliability Matters Most, Trust THERM-A-GAP™ GEL 50VT

September 26, 2023

Whether in homes, on highways or high in the sky, there are countless products consumers and companies depend on every day to make their lives safer and more comfortable. These high-performing applications generate large amounts of heat and are often used in volatile conditions, so it’s imperative that the thermally conductive components within them can be trusted to perform consistently and correctly.

Take automobiles, for instance. A standard day of driving may mean that the car sits outside in very warm temperatures, navigates a bumpy construction zone or encounters a jarring pothole. Through all of these circumstances, the car’s technology including safety devices like the Advanced Driver Assistance Systems must function accurately and without delay.

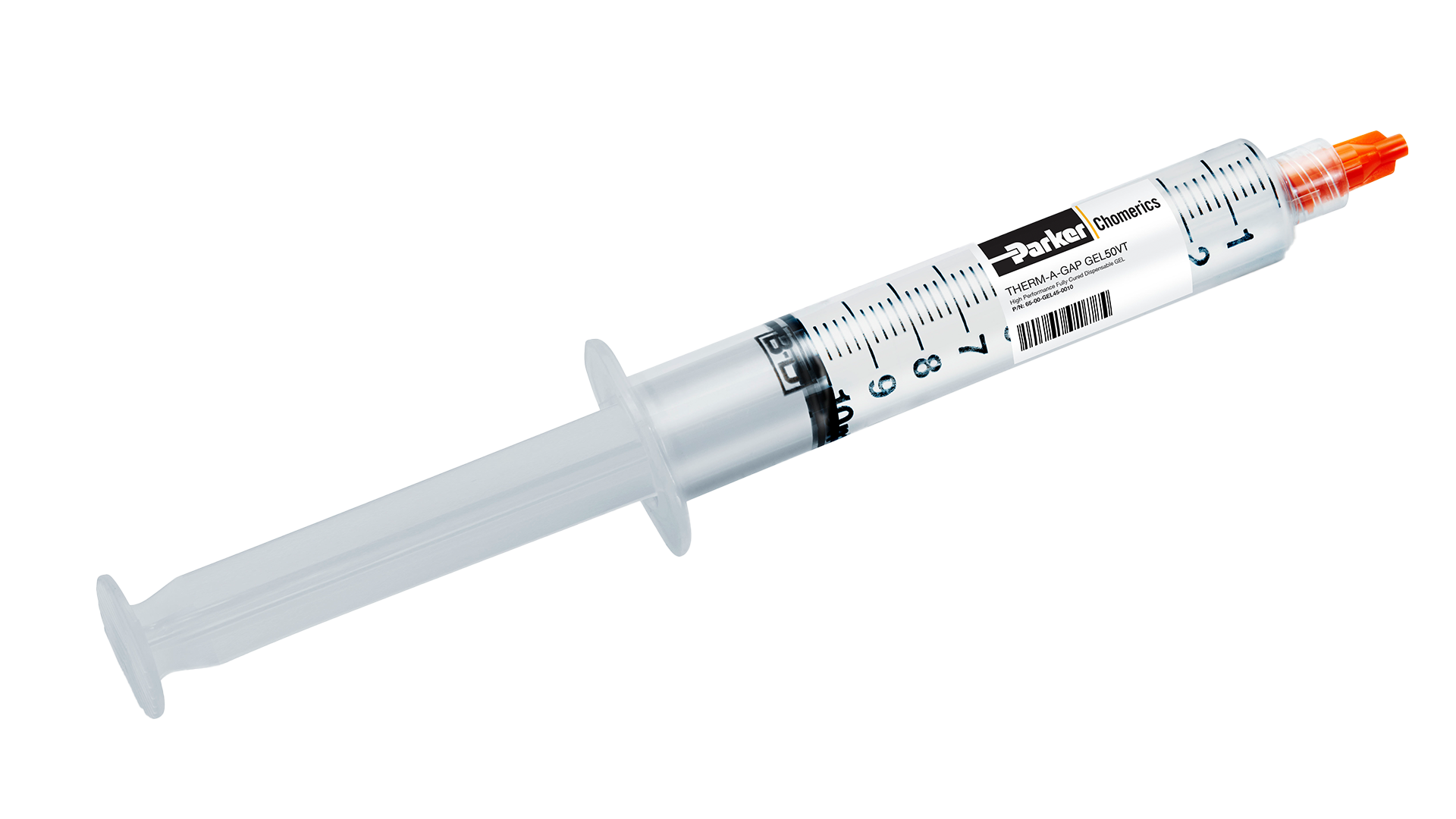

THERM-A-GAP™ GEL 50VT, the newest addition to the THERM-A-GAP GEL family from Parker Chomerics, is our most reliable thermally conductive gel offering yet and the perfect fit for these challenging scenarios. Boasting 5.2 W/m-K thermal conductivity, this high-performance, one-component, dispensable thermal interface gel material was developed to conduct heat from electronics to heat sinks or enclosures and perform reliably in vertical, high-vibration, and harsh environments. It can be used in any industry where applications require reliability in harsh conditions.

THERM-A-GAP GEL 50VT has been extensively tested to exceed expectations and surpass requirements. During development, this gel was subjected to a number of rigorous long-term reliability tests such as automotive slump, high-vibration testing and telecommunications thermal verification processes.

It was specifically designed to support mission-critical applications that rely on consistent thermal performance over the course of hundreds or thousands of cycles and many years of continuous operation. For example, in our testing we’ll execute temperature fluctuations for 1000 cycles to prove that it performs and doesn’t degrade in all situations our customers may face. By overshooting and testing for longer cycles than our customers will need, they can rest assured that THERM-A-GAP GEL 50VT can be trusted. In all our tests, its thermal performance didn’t degrade and, in many cases, actually improved over time.

And, our customers have put THERM-A-GAP GEL 50VT to the test as well, making sure it will perform to their unique and exact specifications. They have looked at circumstances such as vibration in large gaps, thermal reliability testing, and physically distressing the materials before testing the thermal performance. Our customers’ products are often required to perform in extreme environments, and we’re delighted that they’ve found THERM-A-GAP GEL 50VT to be up to the challenge and have shared their findings with us.

For instance:

- A telecommunications customer put THERM-A-GAP GEL 50VT through their thermal reliability verification process.

- A consumer product customer followed their thermal material qualification plan to make sure THERM-A-GAP GEL 50VT was up to par.

- There are multiple tests our automotive customers have shared. Thermal slump testing is key to them, where they put materials into a vertical application to make sure it stays in place through thermal changes. Additionally, they test for ISO and GMW 3172 compliance to ensure parts meet environmental and durability requirements.

In all these situations and more, THERM-A-GAP GEL 50VT has consistently demonstrated its reliability. As an added bonus, it is designed for easy application and rework, requiring no mixing or curing. It can be dispensed at various bond line thicknesses to take up gaps created by assembly or manufacturing tolerances.

As with all thermal gels from Parker Chomerics, THERM-A-GAP GEL 50VT is formulated to accommodate today’s high-performance and high-reliability electronics while being ideal for automated dispensing machines and field repair situations.

Ben Nudelman

Global Market Manager

Parker Chomerics

THERM-A-GAP

GEL 50VT

Parker Chomerics THERM-A-GAP™ GEL 50VT is a reworkable, high performance, one-component, dispensable thermal interface gel material with 5.2 W/m-K typical thermal conductivity. GEL 50VT was developed to conduct heat away from electronics to heat sinks or enclosures and to perform reliably in vertical and/or high vibration applications. The “VT” suffix in the product name stands for “Vertical Tackiness.”

Solutions for Thermal Interface Materials

Parker Chomerics thermal interface materials transfer heat from electronic components to heat sinks and are used to eliminate air gaps from the interface. Our THERM-A-GAP® materials deliver lower thermal impedance, higher thermal conductivity and greater compliance and conformability to both microelectronics and large scale electronics.

Quality & Reliability that Ensure the Utmost Satisfaction

Our parts are designed and manufactured to perform precisely as advertised, meeting and exceeding all necessary specifications.

Solving EV Charging Station Design Challenges: Thermal Interface Materials and EMI Shielding Solutions

Electric vehicle (EV) battery charging stations, also known as EV charging stations or EVSE (Electric Vehicle Supply Equipment), consist of various electronic components and systems that work together to safely and efficiently charge the batteries of electric vehicles. Like most modern, high power electronics, these devices must overcome challenges associate with thermal management and electromagnetic interference (EMI) shielding in order to operate properly and effectively.

Non-Silicone Dispensable Thermal Gel for Automotive Infotainment and Camera Modules

Automotive electronics designers and engineers have been working with component suppliers to push the boundaries of material properties used to maintain long term reliability of these AVNT and Infotainment systems. The basis for long term reliability has been higher performance processors and chips, leading to secondary design concerns. Electronic modules have to be electrically shielded to prevent interference from nearby modules and also cooled to prevent overheating, a leading cause of electronic device failure. In the case of safety features, device failure is not an option.

Safeguarding Alternative Energy with Engineering Innovation

Around the world, businesses and consumers alike are turning their attention to alternative energy sources such as solar, wind and hydropower.

This growing interest isn’t just hype; it’s backed by large investments in green, sustainable energy, and many companies are hard at work developing a broad suite of innovative products to meet the demand.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.