How To Manage Cooling in EV Motors with Plastic

April 13, 2023

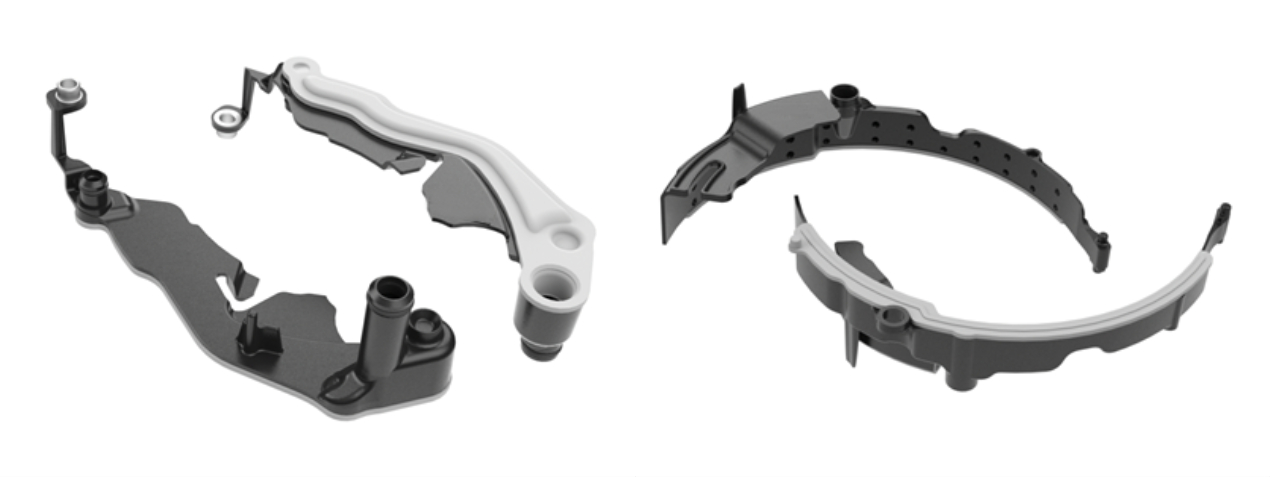

Managing the high temperatures that routinely build within high-torque electric motors is an ongoing challenge for automotive manufacturers. As the engines work hard, particularly when engaged in an activity such as pulling a trailer or accelerating quickly, the motor gets very hot, making integrated cooling through ongoing hydraulic fluid applications to the stator mission-critical.

Plastic components provide a low-cost, space-saving solution, enabling Original Equipment Manufacturers (OEMs) to meet the integrated cooling requirements of high-torque electric motors while enjoying the many other perks of this engineering innovation. For instance, by switching from traditional metal parts to plastic, customers can realize a weight reduction of 83g and utilize laser welding, which allows the plastic components to fit into tight cavities without producing debris during the welding process.

These plastic products are backed by machine-based process monitoring, ensuring each manufacturing and assembly task is completed thoroughly and correctly before operators move on to the next step. All molding machines from Parker Chomerics have built-in sensors and cameras that provide checks and balances every step of the way. These devices monitor the setting as well as the result, measuring actual performance characteristics and verifying important quality standards are met, including the part used, proper alignment, and injection pressure in the mold.

Machine-based process monitoring ensures:

- 24/7 real-time monitoring of every shot

- Immediate notification of a potential problem

- Control limits can be developed during the mold qualification stage, and alarms and automatic parts diversion via reversing conveyors will trigger if those limits are exceeded

- Process parameters are measured, not just finished parts

- The opportunity for six sigma quality

- A predictive maintenance tool for processing equipment

This thorough approach to process monitoring allows us to guarantee zero defects, giving our OEM customers a quality plastic component that meets their unique design requirements every time.

Sarah Kuhn

Marketing Communications Manager

Parker Chomerics

PREMIER Conductive Plastic Pellet Materials

Parker's selection of EMI-shielding conductive plastic pellet materials includes conductive ATCA faceplate blanks; polyetherimide-based pellets for shielding, high-temperature performance, low smoke generation, and chemical resistance; PBT-based pellets for metal-to-plastic housing electronics conversions; and PC/ABS-based alloys to enable stable electrical, mechanical, and physical performance. Learn More.

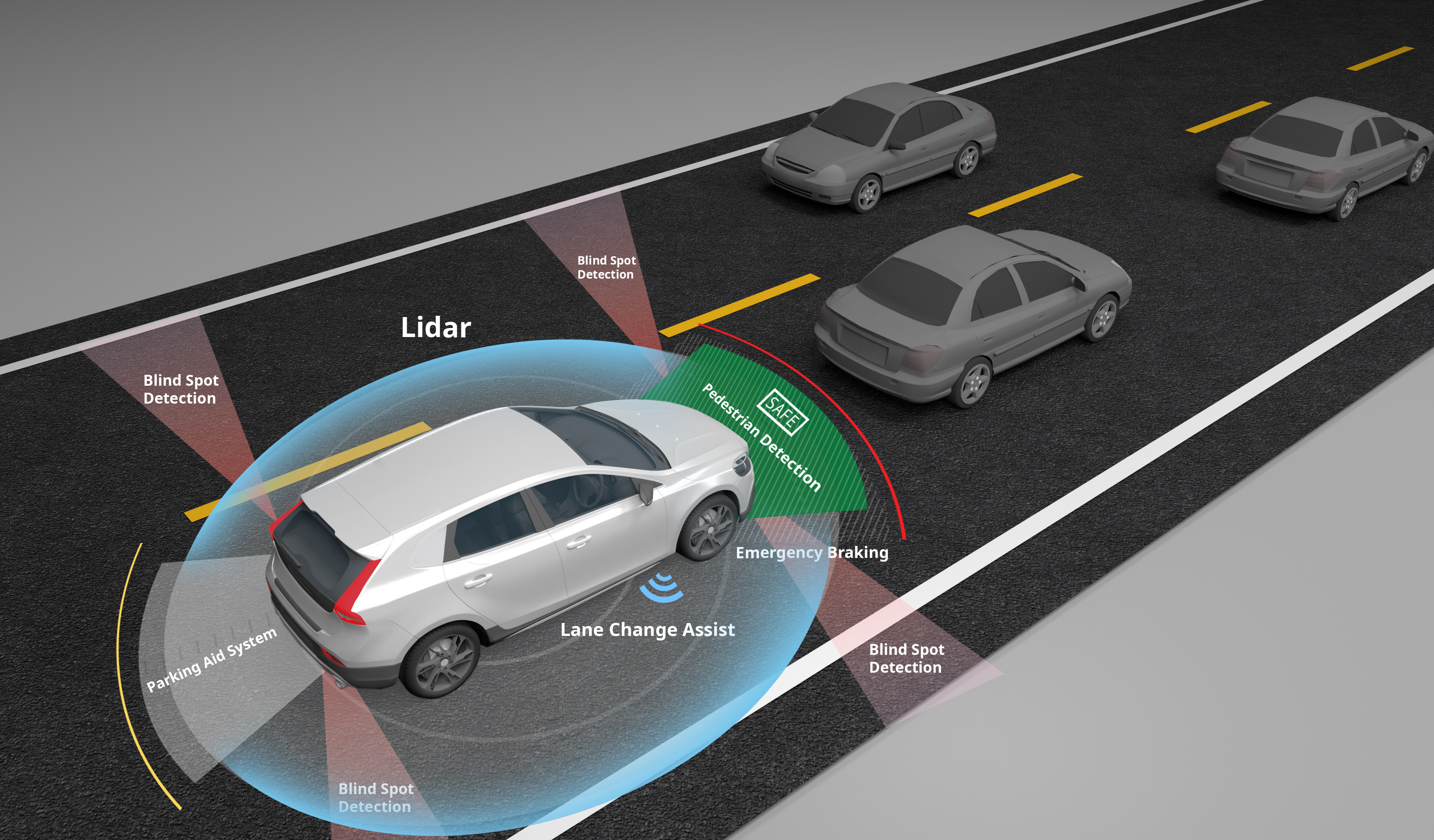

Solutions for ADAS

Advanced Driver Assistance System (ADAS) modules and infotainment panels have led the way in terms of advancement of electronic systems within passenger vehicles. Learn more about Parker Chomerics solutions for ADAS applications.

PROVEN PERFORMANCE

The leader in Thermally Conductive Interface Materials.

We continue to advance technologies to bring new and enhanced capabilities and efficiencies.

Cooling Innovation for EV Motors with a Zero-Defect Guarantee

Plastic components provide a low-cost, space-saving solution, enabling Original Equipment Manufacturers (OEMs) to meet the integrated cooling requirements of high-torque electric motors. These products are backed by machine-based process monitoring, ensuring each manufacturing and assembly step is completed thoroughly and correctly.

Solving EV Charging Station Design Challenges: Thermal Interface Materials and EMI Shielding Solutions

Electric vehicle (EV) battery charging stations, also known as EV charging stations or EVSE (Electric Vehicle Supply Equipment), consist of various electronic components and systems that work together to safely and efficiently charge the batteries of electric vehicles. Like most modern, high power electronics, these devices must overcome challenges associate with thermal management and electromagnetic interference (EMI) shielding in order to operate properly and effectively.

Non-Silicone Dispensable Thermal Gel for Automotive Infotainment and Camera Modules

While “electrification” and “EV” buzzwords have taken center stage in conversations about vehicle electronics, drivers of all vehicle types as well as passengers and pedestrians are the beneficiaries of advanced safety, navigation, and entertainment systems.

We’re constantly innovating in our drive to create the most advanced electric vehicle solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.