What is ADAS?

February 27, 2023

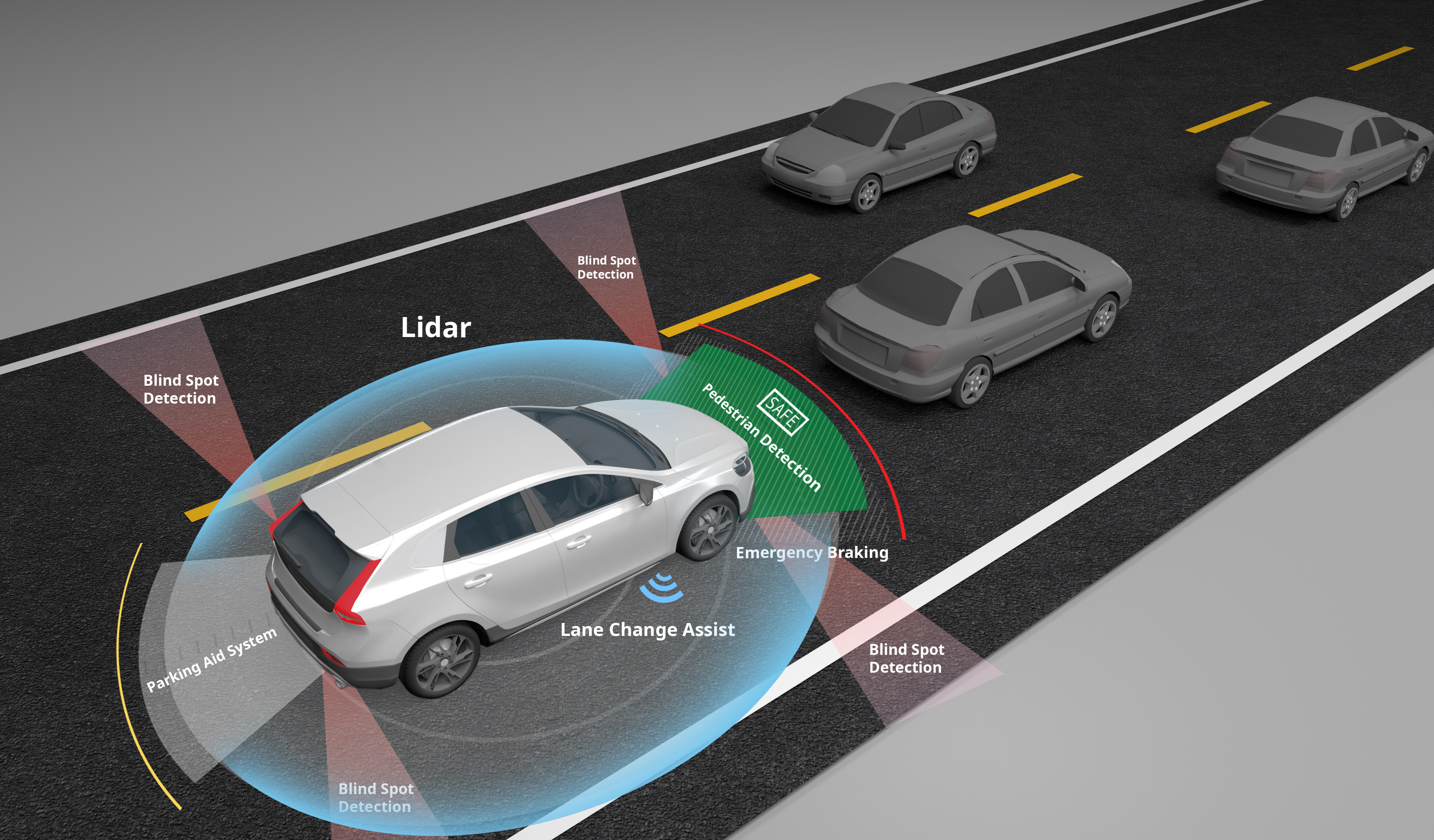

The modern car driving experience has evolved significantly in both safety and convenience, thanks to technology innovations in advanced driver-assistance systems (ADAS). Using a human-machine interface that helps drivers anticipate and react to potential hazards, the early warnings and automated systems built into these electronic technologies aim to prevent car accidents or minimize the impact of those that can’t be avoided.

ADAS is widely available; these systems are built standard to most modern vehicles, and individual features and even entire systems can be added after market in many cases.

Examples of ADAS

- Adaptive cruise control

- Anti-lock brakes

- Forward collision warning

- High-beam safety system

- Lane departure warning

- Traffic signal recognition

- Traction control

According to the National Safety Council, ADAS could potentially prevent 20,841 deaths per year, or about 62% of total traffic deaths.

Engineering Innovation You can Trust

There’s a lot riding on ADAS, and it’s importantly that the systems function properly, every single time. To make this happen, it takes many small parts and a whole lot of engineering genius.

Thermally conductive materials are an essential part of consistently performing ADAS. Each of these safety devices has its own computer with many small crevices and gaps that need protection from high temperatures and environmental changes. From thermally conductive gels to non-silicone dispensable thermal gels, picking the right components for the job is critical.

Additionally, the complex sensor and radar assemblies used in modern automobiles are subject to harsh electromagnetic interference (EMI) from surrounding electronics, not to mention EMI radiation from the device itself! As devices become more and more powerful, the signals they emit can cause internal competition, leading to data inaccuracies that decrease safety and reliability. Without proper management, this can cause improper working conditions that allow chips to interfere with other chips. EMI-shielding materials are an essential part of ensuring these systems function properly. The materials utilized must be high-performing and flexible, as design requirements are usually vague and broad.

As vehicles and their drivers rely more on ADAS, automotive camera and motion sensor companies will need to expand their technologies to meet these needs while staying in compliance with stringent government requirements.

Learn more about Parker Chomerics' solutions for ADAS here.

Metal-to-Plastic Conversion of Automotive Driver Safety Modules

In this webinar we discuss the benefits of metal-to-plastic conversion combined with integrated assembly manufacturing. Especially useful for automotive electronics housings such as those designed for advanced driver assistance systems (ADAS) like adaptive cruise control, lane departure warning, and blind spot monitoring.