parker.com/chomerics > Blog Posts & Articles

Blog Posts & Articles

Empowering Defense Drones for Military Applications

EMI Shielding / Aerospace & Defense

Reliable performance in these RF‑dense, harsh conditions depends on disciplined electromagnetic interference (EMI) shielding and electromagnetic compatibility (EMC) control as well as environmental robustness. These criteria are typically validated against MIL‑STD‑461/464 and MIL‑STD‑810, with selected elements of RTCA DO‑160 as applicable. Parker Chomerics provides several reliable solutions to mitigate these issues.

EMI Shielding Honeycomb Vent Panels for Secure Facilities and Shielded Rooms

EMI Shielding / IT / Data Centers

Modern data centers, which often include secure facilities and shielded rooms, have many requirements to keep them performing optimally and continuously. In applications where there are high-security environments or that contain confidential information, there are many individual buildings and rooms that must be EMI shielded while maintaining proper air flow and air handling. Learn how our honeycomb vent panels meet these needs.

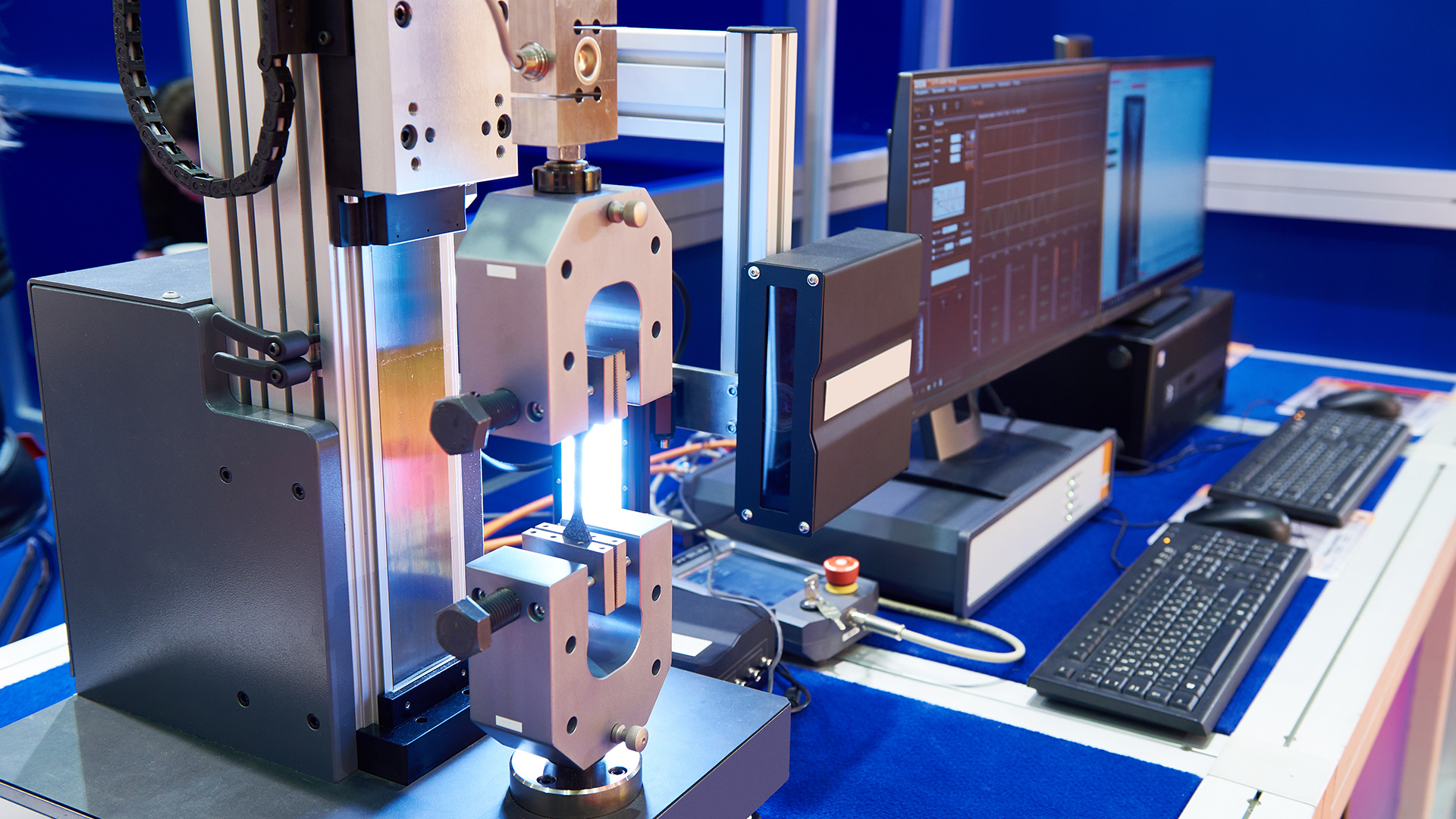

EMI Shielding and Thermal Considerations for Test Fixtures

Thermal Management / EMI Shielding / Telecom

To ensure that applications function reliably and as intended, it’s important to include thorough testing in the development process. That includes EMI shielding, electrical grounding and thermal management for the end device as well as the test fixtures themselves. Learn more about the unique requirements of test fixtures.

Next-Generation Materials for Telecommunications Applications

Thermal Management / EMI Shielding / Telecom

The telecom industry is undergoing rapid innovation, largely driven by big data and AI markets who are pushing the limits of high-speed communications and connectivity. Telecom applications encompass many devices that facilitate data transmission, including ground or rooftop cell phone towers and all the boxes and communications modules that those contain all the way down to the routers and modems found in office buildings and homes. These 5G, WiFi and Internet of Things (IoT) devices keep consumers connected and businesses thriving, and they require constant connection to keep data flowing at all times.

Accelerating Data Transmission with Form-In-Place Gasket Solutions for Optical Transceivers

EMI Shielding / IT / Data Centers

Data transmission applications create, generate and store large quantities of data, especially when used for AI or in data centers. It’s important to take steps to remove bottlenecks, ensuring that data can get to where it needs to go as quickly and effectively as possible.

Supporting Embedded Computing in Defense Aerospace Applications

Thermal / EMI Shielding / Defense

Specialized computer systems known as embedded computing are gaining traction in many industries. These systems consist of both hardware and software that is doing a lot of processing, somewhat similar to a data center or a server but in a smaller system. One common application for embedded systems is defense aerospace applications such as mobile applications, ground vehicles or military ships. In these cases, embedded computing does all the data processing of communications as well as command and control systems directly on these military vehicles or out in the field somewhere.

Thermal Solutions for Tight Semiconductor Cavities

Thermal / EMI Shielding / Consumer Electronics

Today’s tech landscape is rapidly evolving, especially in the automotive and communications sectors. Driven by the increased adoption of 5G and 6G as well as advances in data processing, data speeds, and internet connectivity, all sorts of applications from medical devices to EV car batteries are getting faster, more efficient, and more connected.

Improved Thermal Management for Liquid Cooling Features in Data Centers

Thermal / IT

Modern IT applications and data centers are tasked with managing increasingly large amounts of data, and that can introduce some real heat challenges. Not only are these applications and centers processing vast amounts of data at high speeds, they also must be able to run continuously for many years. The historical approach of air cooling—blowing cool air over some of the features to reduce heat—often proves inadequate to maintain the required temperatures while promoting continuous operation.

EMI Shielding for Finely Calibrated Test and Measurement Equipment

EMI Shielding / General Industrial

Test and measurement equipment is a necessity for the innovation of cutting-edge technologies and electronics. This category covers a broad range of electronic devices that often work in the background during the development/testing of other electronics and are used to take measurements provide accurate readings of electromagnetic properties.. Examples of these types of devices include digital multimeters, oscilloscopes, signal generators, spectrum analyzers, and power supplies. Test and measurement equipment can also describe devices used to measure thermal or physical properties such as thermal cameras and torque gauges or force probes.

Improve Power Tool Performance with Thermal Gap Pads

Thermal / EMI Shielding / Consumer Electronics

From commercial job sites to personal home use, power tools such as drills, impact drivers and saws serve a crucial role in projects large and small. These devices are mostly battery powered, which means they are handheld, mobile systems. As they rise in popularity, there is a need for increased battery life and performance as well as connectivity in some cases. That’s because some of these devices incorporate smart features while in use such as regulating time or setting other specific functions.

Increase Security in POS Devices with EMI Shielding

EMI Shielding / Consumer Electronics

To facilitate modern commerce requirements, point of sale (POS) devices are getting more and more sophisticated. These devices, such as tap to pay and square credit card readers, can be integrated into touch screens or used as just the card readers themselves. In many cases these POS capabilities are utilized in mobile devices, such as the credit card readers you might see in restaurants and cafes which allow servers to take payment and provide a receipt at the table.

How TIMs can be Automated in High-Volume Assembly Processes

Thermal / Consumer Electronics

There are many different kinds of thermal interface materials (TIMs) that are utilized in a diverse range of applications, which are all produced at different volumes and in different markets. These thermally conductive, dispensable materials have the ability to cover a variety of gaps and form complex geometries. This ability to conform provides reduced thermal contact resistances, thus reducing temperatures and increasing application efficiency while providing low closure force.

Improve User Experience in Gaming Consoles with Thermal Management and EMI Shielding

Thermal / EMI Shielding / Consumer Electronics

Video game consoles are an integral part of modern entertainment, providing users with an array of virtual experiences from fantasy to real life replications. Gaming consoles can be mobile or hybrid (e.g. Nintendo Switch) or stationery (e.g. Xbox and PlayStation). While these consumer electronic devices aren’t the most powerful applications, they do require a high level of thermal management as they combine a lot technology such as advanced graphics and internet connectivity while processing large amounts of data.

EMI Shielding and Thermal Management Solutions for Reliable Hybrid Diagnostic Imaging

Thermal / EMI Shielding / Life Science

There are several specific design requirements for hybrid diagnostic imaging. One important consideration is the need for extremely precise calibration in order to record accurate measurements in relatively small areas through various layers of the body. To keep these machines working at this level of precision and guarantee accurate imagery, ensuring effective electromagnetic interference (EMI) shielding must be a top priority.

Bolstering the Modern Factory with Automation

Thermal / EMI Shielding / General Industrial

From an automation standpoint, there are many opportunities for technologies such as robotic, monitoring and imaging equipment to perform predictable, repeatable tasks over and over. These robots typically have a control panel or control unit that has a high potential for heat generation and electromagnetic interference (EMI).

Introducing THERM-A-GAP GEL 120: Our Highest Performing Thermal Gap Filler Gel

Thermal / Consumer Electronics

We’re excited to continue pushing the bar and helping our customers accelerate innovation with THERM-A-GAP GEL 120 which offers a game-changing thermal conductivity of 12.0 W/m-K.

How TIMs can be Automated in High-Volume Assembly Processes

Thermal / Consumer Electronics

There are many different kinds of thermal interface materials (TIMs) that are utilized in a diverse range of applications, which are all produced at different volumes and in different markets. These thermally conductive, dispensable materials have the ability to cover a variety of gaps and form complex geometries. This ability to conform provides reduced thermal contact resistances, thus reducing temperatures and increasing application efficiency while providing low closure force.

Solving Overheating Issues in Computers and Servers: THERM-A-GAP PAD 10

Thermal / IT / Data Centers

In the fast-paced world of computing, overheating is one of the most critical challenges affecting the performance, longevity, and reliability of systems. Computers and servers generate significant heat, and without proper thermal management, components can degrade, slow down, or even fail. Parker Chomerics has introduced the THERM-A-GAP PAD 10, a thermally conductive gap filler pad designed to address this issue effectively. With its ultra-low hardness and excellent thermal conductivity, this solution ensures optimal heat dissipation, keeping computing systems running smoothly and efficiently.

THERM-A-GAP PAD 10: The Ultimate Solution for Thermal Management

Thermal / Automotive

The THERM-A-GAP PAD 10 is a breakthrough in thermal interface materials, offering an ultra-low hardness of 35 Shore 00 and an impressive thermal conductivity of 1.0 W/m-K. This combination makes it an ideal choice for applications requiring minimal deflection force and optimal heat dissipation. Whether you are designing consumer electronics, automotive ECUs, or LED lighting systems, THERM-A-GAP PAD 10 ensures effective thermal management without compromising on performance.

Superior Thermal Gel for ADAS and Modern Automotive Heat Management: THERM-A-GAP GEL 75VT

Thermal / Automotive

To meet the specific needs required by ADAS, Parker Chomerics is excited to introduce THERM-A-GAP GEL 75VT, the newest and highest-performing member of the VT product family. The “VT” suffix in the product name stands for Vertical Tackiness, indicating that these products are specifically designed to endure the high vibrations that come with cars’ vertical orientations. GEL 75VT is a one-component thermal interface material that is form stable and retains its position despite this environment, meeting thermal needs as well as vibration requirements. It was developed around Automotive industry-specific reliability requirements and formulated with adhesion promoters to further improve reliability.

Prevent Corrosion on Airplane Antennas with METALASTIC EXP-URE

EMI Shielding / Aerospace & Defense

Parker Chomerics Metalastic™ EXP-URE urethan-filled expanded aluminum gaskets meet this need and more, providing an electrically conductive, fluid and pressure-sealing solution for exterior mounted accessories for a variety of flange-to-flange assemblies. Developed to minimize galvanic corrosion of interfacing surfaces that require electrical bonding, these fully-cured gaskets protect the antennae from fluids while maintaining electrical conductivity for lightning strike grounding or electromagnetic shielding.

Introducing CHO-SEAL 1299: A Low-Durometer EMI Shielding Elastomer Gasket

EMI Shielding

CHO-SEAL 1298, an electrically conductive elastomer gasket, is among our most trusted products, providing customers in many industries with a reliable electromagnetic interference (EMI) shielding solution. However, in some cases, the hardness of 1298 is not suitable as it requires more force to compress than the application can provide. To address this need, we are excited to introduce CHO-SEAL 1299, providing customers with the performance they trust from CHO-SEAL 1298 in a softer form.

Facilitating Air Cooling for Data Centers

EMI Shielding / Telecom/IT

Thermal management is an important consideration when designing high-performing data centers that are capable of carrying an intense and ever-growing workload. Learn how EMI shielding air ventilation panels are helping data centers work harder.

EMI Shielding, Environmental Shielding and Thermal Management for Marine Drones

Thermal / Automotive

Drones have gained popularity because of their versatility, relatively low cost compared to other monitoring/measurement equipment, and reduction of risk to operators. These drones can operate either on the water’s surface or underneath it, and some are designed to move while others are more stationary. For added flexibility, some devices can be tethered, and in other cases they utilize WiFi communication.

Why Do TIMs Break Down at High Voltages?

Thermal / Automotive

Thermal interface materials (TIMs) are commonly used to eliminate air gaps present when an electronic component and its heat dissipating component (heat sink, vapor chamber, cooling pipe, etc.) are mated together. TIMs are typically comprised of two major constituents; the polymer binder, which allows for the TIM to be soft and conformable (necessary to displace air during the assembly process), and the ceramic filler particles, which provide the TIM with a high level of thermal conductivity. While both the polymer binder and the ceramic filler particles are typically electrically insulating, if the TIM is subjected to a high enough voltage differential, electrical current can still short its way through. This phenomenon is known as electrical breakdown, and the voltage at which this breakdown occurs is referred to as the breakdown voltage.

How do Driver Monitoring Systems Work?

Thermal / Automotive

Within the automotive industry, there has been an increasingly large focus on the development and usage of Advanced Driver-Assistance Systems (ADAS) to ensure the safe operation of motor vehicles for the everyday driver. ADAS are becoming standard equipment within most modern vehicles and provide many safety features such as lane departure warnings or traffic signal recognitions. These systems play an important role in preventing or minimizing the impact of car accidents by using human-machine interfaces to help drivers anticipate and react to potential hazards.

Regulating Temperatures in Electric and Hybrid Vehicles: THERM-A-GAP CIP 60

Thermal / Automotive

Electric vehicles (EVs) and hybrid vehicles (HEVs & PHEVs) are becoming increasingly prevalent to reduce the environmental detriments produced by traditional combustion engine (ICE) vehicles. The use of stored electrical energy as opposed to stored chemical energy (gas) requires the use of large battery packs to supply the electric drivetrain, and therefore the electric motors, with electrical power.

The Future of Electric Vehicle Battery Thermal Management: THERM-A-GAP CIP 60

Thermal / Automotive

To address the specific needs of automotive manufacturers and their tier suppliers, Parker Chomerics is pleased to introduce THERM-A-GAP® CIP 60. As one of our highest-performing solutions in this area, THERM-A-GAP® CIP 60 is a two-component (2K) dispensable, cure-in-place thermal gap filler with a thermal conductivity of 6.0 W/m-K. It serves as an alternative to hard-curing dispensable materials while improving upon standard application methods associated with thermal gap filler pads.

Empowering the Latest Consumer Electronic Innovations

EMI Shilding / Thermal / Consumer Electronics

Consumer technology gadgets all have one thing in common: To operate as intended, they must be designed with proper EMI shielding and thermal management. Learn how Parker Chomerics is solving this challenge.

Designing for Success: EMI Shielding and Corrosion Resistance in Naval Applications

EMI Shilding / Aerospace & Defense

When designing electronic devices for naval and shipboard applications, engineers must address unique challenges such as electromagnetic interference (EMI) shielding, corrosion resistance, and environmental sealing. These considerations are crucial for ensuring optimal performance and long product life in harsh aquatic environments. Parker Chomerics offers specialized solutions, including conductive elastomers like CHO-SEAL, which provide both EMI shielding and environmental protection. Our experienced engineering team is committed to helping you navigate these challenges and deliver reliable solutions tailored to your specific needs.

Improve Screening and Security Equipment Performance with Reliable EMI Shielding

EMI Shilding / General Industrial / Aerospace & Defense

Driven by factors such as security and healthcare advancements as well as a growing concern about public safety, screening devices are all around us playing an important role in peace of mind wellbeing. Learn more about these applications and the EMI shielding components that keep them working reliably.

Thermal Management In LED Lighting

Thermal / General Industrial

LEDs are very popular lighting choices for businesses and homes due to their efficacy and endurance, and proper thermal management is required to keep them operating optimally. Learn more about thermal management in LEDs.

Enabling Comfortable, Safe and High-Performing Wearable Devices

Thermal / EMI Shielding / Life Science

From health and fitness trackers to medical devices, wearable devices are one consumer electronic trend that shows no signs of slowing down. Learn about the unique EMI shielding and thermal requirements of these devices.

Meeting Customers’ Needs With New Thermal Greases

Thermal / General Industrial

Introducing four new THERM-A-GREASE formulations, designed to provide our customers with options to cover a wide range of applications from low-heat basic computers or industrial electronics to high-heat applications such as LED lighting.

Streamline Supply Chains with Parker Chomerics: The Advantages of Integrated EMI Shielding and Thermal Interface Assemblies

EMI Shielding / Integrated Assemblies

While we can’t control the future, streamlining the steps and players involved in a supply chain can go a long way towards insulating it from potential hiccups such as raw material shortages or geopolitical conflicts. Learn how integrated assembly manufacturing processes can help ensure supply chain resiliency.

Achieve EMI Shielding Without Galvanic Corrosion in the Defense and Aerospace Industries

EMI Shielding / Aerospace and Defense

Galvanic corrosion is a costly headache for U.S. government defense and aerospace applications, to the tune of more than $21 billion a year in rework and increased maintenance needs. Learn how to manage this challenge.

Improved Safety and Reliability in Micromobility Devices

EMI Shielding / Thermal / Transportation

Micromobility devices have revolutionized urban transportation, providing users with convenient and affordable options for short-distance travel. However, the batteries generally utilized in them introduce some potential safety and reliability concerns. Learn about the potential risks and how to mitigate them.

Empowering High-Speed I/O Data Connections With Advanced EMI Shielding Solutions

EMI Shielding / Consumer Electronics / Telecom/IT

Data centers associated with high-performance computing are constantly being asked to work harder and faster, and that’s not going to change anytime soon. Learn how we’re creating EMI shielding solutions that are up to the challenge.

Why High Thermal Performance Alone isn’t Enough Anymore: The Next Generation of Thermal Gap Filler Pad

Thermal / Consumer Electronics / Telecom/IT / Alternative Energy

AI Processing Hardware. Telecommunications Infrastructure. Advanced Automotive Electronics. Mission Critical Avionics and Defense Electronics. IoT Modules. Wearable Medical Devices. PAD 80LO represents a modern solution to the next generation of electronics thermal management.

Advanced Battery Energy Storage Systems (BESS) Solutions: THERM-A-GAP CIP 60

Thermal / Alternative Energy

Battery energy storage systems generate large amounts of heat, and they need high-performing thermal solutions to help them perform safely and optimally. THERM-A-GAP CIP 60 was designed for this high-stakes scenario.

Solving the Problems that Advanced 5G Presents

EMI Shielding / Thermal / Telecom

Discover how Parker Chomerics is tackling the challenges of advanced 5G technology with rigorous testing and innovative solutions designed to meet the demands of high-frequency environments.

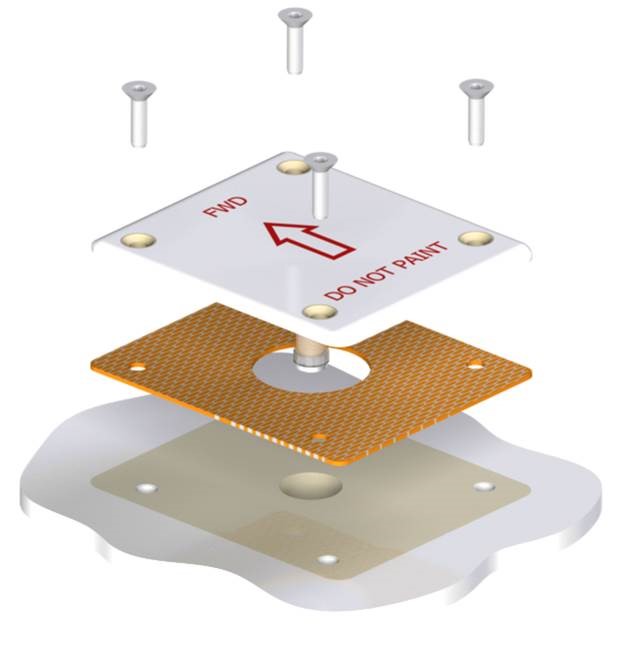

How are Drones Electrically Grounded?

EMI Shielding / Aerospace & Defense

Providing an intentional electrical ground for aerial drones, or Unmanned Aerial Vehicles (UAVs), is crucial for application performance and safety. Learn which EMI shielding gaskets are right for the job.

Conductive Elastomers for Electrical Bonding in Aerospace Connectors

EMI Shielding / Aerospace & Defense

Electrically conductive gaskets enhance EMI shielding and electrical bonding in metal enclosures through primarily RF bonds, achieving resistance as low as 2.5mΩ with metal bonding straps, or screws alongside flat or O-ring gaskets where traditional bonding methods are impractical. However, these connections may experience a perplexing increase in electrical resistance over time, attributed to gasket instability caused by over-compression, particularly in flat gaskets with a maximum deflection of around 15% of their initial thickness, presenting challenges in avoiding damage due to thickness variations and leading to resistance increase even with metal-to-metal contact.

How to EMI Shield Servers and Data Centers

EMI Shielding / Telecom/IT

As electronics get faster and more powerful, high-frequency EMI shielding becomes more important than ever. Learn how these dynamics impact data centers and servers and how high-performing gasketing options make all the difference.

Enhancing Electric Car Charging Stations with Powder Coating and CHO-MASK II

EMI Shielding / Automotive / EV

When it comes to powder coating electric car charging stations, CHO-MASK II emerges as a standout solution. CHO-MASK II EMI foil tapes offer unparalleled performance in providing a conductive, non-corroding surface on painted metal enclosures, making them an ideal choice for masking applications in powder coating.

EMI Shielding for Powder Coated and Painted Enclosures with CHO-MASK II EMI Foil Tapes

EMI Shielding / Automotive / EV

For electronic enclosures, safeguarding against electromagnetic interference (EMI) while maintaining an electrical ground is paramount. However, the powder-coating processes frequently utilized on these enclosures inhibit the proper electrical path required for high EMI shielding and grounding performance. This is where the CHO-MASK II family of EMI masking tapes step in as a reliable, easy-to-use solution to ensure that a conductive electrical path is maintained.

Space Tech Essentials: EMI Shielding & Thermal Materials Guide

Thermal / EMI Shielding / Aerospace & Defense

Gap fillers are an important component in thermal management for electronic devices. A class of thermal interface materials (TIMs), gap fillers are specifically designed to fill small or large gaps between heat-generating and heat-dissipating surfaces. Eliminating these gaps helps improve heat transfer and prevent overheating that can otherwise damage components and negatively impact performance.

What Does a Gap Filler Do?

Thermal

Gap fillers are an important component in thermal management for electronic devices. A class of thermal interface materials (TIMs), gap fillers are specifically designed to fill small or large gaps between heat-generating and heat-dissipating surfaces. Eliminating these gaps helps improve heat transfer and prevent overheating that can otherwise damage components and negatively impact performance.

How to Shield Against EMI

EMI Shielding

Electromagnetic interference (EMI) is a high-priority concern for any design involving electronics. Caused by both natural and manmade electromagnetic fields, EMI is unwanted noise or interference within an electrical circuit that can slow down or even halt a system’s performance. And as applications become faster, such as what we see with 5G mm Wave technology, the challenge of EMI becomes even more complicated and with higher stakes.

What is the Best Thermal Interface Material?

Thermal

Thermal interface materials (TIMs) are essential components used to safeguard equipment and devices from excessive internal heat and harmful electromagnetic interference. They are placed between heat-generating components like semiconductors or batteries and cooling features, where they conduct heat away.

As devices become smaller and generate more heat, the performance and usability demands on TIMs increase, leading to a variety of TIM options. The most popular TIMs are thermal gels and thermal pads. However, choosing the "best" TIM is not just about performance; it also depends on the specific application, and other physical and regulatory properties must be taken into account.

Meeting the Needs of Automotive OEMs with Collaborative Engineering Innovation

EMI Shielding / Plastics / Automotive / EV

As the number of electric vehicles (EVs) on our roads continues to surge, it's clear that these advanced machines have their own distinct set of engineering demands. Paramount among these is the need to maintain the motor's cool temperature while safeguarding it from harmful fluids and debris, ensuring it operates at peak performance and safety.

Answering this call, Parker Hannifin has created a pioneering solution - high-precision, injection-molded plastic covers for EV cooling systems. This innovative, value-added solution harnesses the power of two distinct Parker technologies, providing industry-leading original equipment manufacturers (OEMs) with a tried-and-tested answer to their needs.

When Reliability Matters Most, Trust THERM-A-GAP GEL 50VT

Thermal

THERM-A-GAP™ GEL 50VT, the newest addition to the THERM-A-GAP GEL family from Parker Chomerics, is our most reliable thermally conductive gel offering yet and the perfect fit for these challenging scenarios. Boasting 5.2 W/m-K thermal conductivity, this high-performance, one-component, dispensable thermal interface gel material was developed to conduct heat from electronics to heat sinks or enclosures and perform reliably in vertical, high-vibration, and harsh environments. It can be used in any industry where applications require reliability in harsh conditions.

THERM-A-GAP GEL 50TBL: The Next Generation of Thin Bond Line Thermal Interface Materials

Thermal

Miniaturization. Higher Power. Higher Component Density. These are the trademarks of many modern electronic devices. While these trends are helping push the boundaries of what devices can do, they come with their fair share of challenges. Most notable of these challenges is the long-term reliability of electronics associated with a controlled operating temperature range. Thermal Interface materials (TIMs) are improving in lock step with modern electronics but must get more efficient and be able to operate in smaller gaps. THERM-A-GAP GEL 50TBL (TBL = Thin Bond Line) is the Parker Chomerics solution to thin bond line applications and an alternative to current greases and phase change materials (PCMs).

Proven, Adaptable Solutions for Electrical Grounding

EMI Shielding / Electrical Grounding

Parker Chomerics has been helping manufacturers rise to the occasion for a long time. One proven solution is the line of fabric-over-foam (FoF) conductive gaskets, an excellent economical choice for low-closure force electronics applications requiring grounding and/or EMI shielding. By combining the conductive properties of an electrically conductive fabric and the conformability of a foam core construction, the Chomerics SOFT-SHIELD FoF product family ensures both high conductivity and reliability. The SOFT-SHIELD 3500 FoF gaskets use a urethane foam core and is ideal for most applications.

EMI Protection Meets Design Freedom with CHO-SEAL 6750

EMI Shielding

Parker Chomerics is the global leader in thermal interface materials and EMI shielding solutions, and we continue to deliver engineering innovations to help companies protect their applications from EMI. Today we’re excited to introduce CHO-SEAL® 6750, a new offering from the trusted CHO-SEAL family of nickel-plated graphite-filled elastomers. CHO-SEAL 6750 is a low durometer, nickel-graphite filled fluorosilicone EMI shielding material. Its high-temperature capability and chemical resistance make it an excellent choice for environmental sealing and EMI shielding.

Solving EV Charging Station Design Challenges: Thermal Interface Materials and EMI Shielding Solutions

EMI Shielding / Thermal / Automotive / EV

Electric vehicle (EV) battery charging stations, also known as EV charging stations or EVSE (Electric Vehicle Supply Equipment), consist of various electronic components and systems that work together to safely and efficiently charge the batteries of electric vehicles. Like most modern, high power electronics, these devices must overcome challenges associate with thermal management and electromagnetic interference (EMI) shielding in order to operate properly and effectively. In this article we will breakdown the common components of EV charging stations and present solutions to common electrical design challenges.

Conductive Materials for Electrical Grounding and EMI Shielding

EMI Shielding / Electrical Grounding

Electrical grounding, or earth grounding, is an important aspect of electrical systems not only for safety reasons but also for reducing electrical noise. Electrical noise, sometimes referred to as electromagnetic interference (EMI) or radio-frequency interference (RFI), can negatively impact the performance of electronic circuits, cause errors in measurements of precision sensors, and lead to the malfunction of sensitive electronic devices.

Best New Fluid and Corrosion Resistant Electrically Conductive Sealants

EMI Shielding / Aerospace & Defense

The next-generation family of fluid and corrosion resistant electrically conductive sealants are here. Polythioether based conductive sealants and gap fillers are proven to be a reliable and a worthy addition to the Parker Chomerics CHO-BOND® family of conductive sealants and adhesives.

How To Manage Cooling in EV Motors with Plastic

EMI Shielding / Plastics / Automotive / EV

Managing the high temperatures that routinely build within high-torque electric motors is an ongoing challenge for automotive manufacturers. As the engines work hard, particularly when engaged in an activity such as pulling a trailer or accelerating quickly, the motor gets very hot, making integrated cooling through ongoing hydraulic fluid applications to the stator mission-critical.

The Essential Guide to Grounding Electronics: Techniques and Best Practices

EMI Shielding / Electrical Grounding

Grounding is one of the most essential – and complicated – parts of manufacturing safe, high-performing electrical devices and products. Learn more common ground and chassis ground as well as materials that can be used to ground electronics.

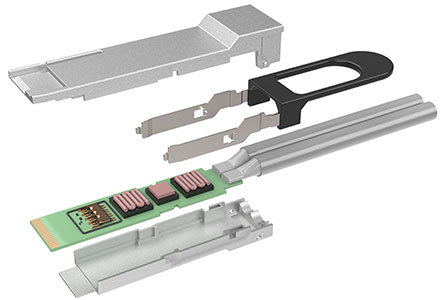

Non-Silicone Dispensable Thermal Interface Material for SSD Modules

Thermal / Telecom/IT / Consumer Electronics

While by no means a new technology, Solid State Drives (SSDs) have shown a marked increase in adoption over Hard Disk Drives (HDDs) at both the consumer and enterprise scale over the last decade. With the advantages of faster speeds, no moving parts, long-term reliability, and quieter operation, SSDs have become the current standard as well as the future for data storage. As storage capacities increase and costs decrease, SSD device manufacturing will continue to grow, some estimating as much as a 15% CAGR through 2030. This increase in SSD devices is across most sub-categories of solid-state drives including SATA and M.2 as well as higher performance variations like PCIe/NVMe.

Protect Equipment with a High-Performing Gap Filler Pad

Thermal / Telecom/IT / Consumer Electronics

New from Parker Chomerics is the THERM-A-GAP PAD 70TP Thermally Conductive Gap Filler Pad. This ultra-soft, ultra-conformable, high-performance product provides a very low hardness (15 Shore 00) solution with 7.0W/m-K thermal conductivity. THERM‐A‐GAP PAD 70TP is designed to provide effective heat transfer between electronic components and their associated cooling features such as heat sinks.

What is Thermal Interface Material?

Thermal

Thermal interface materials (TIM) play an important role in protecting equipment and devices from high internal temperatures and damaging electromagnetic interference. Learn more about the benefits of TIMs and how high-performing solutions such as thermally conductive gels and filler pads can improve product performance.

Improve Assembly Efficiency with THERM-A-GAP GEL 60HF

Thermal

In manufacturing production facilities, every fraction of a section counts. Parts must be made and assembled quickly and correctly to meet customer demand and stay ahead of the competition.

To address this need and give our customers a competitive advantage, we’re proud to introduce THERM-A-GAP GEL 60HF. Part of the Parker Chomerics family of fully cured, silicone-based, dispensable thermal interface materials, this innovative gel is designed for high-performance heat transfer from electronics components to cooling features and flexible for use across industries and applications.

Performance and Elastomeric Benefits in One Thermally Conductive Gap Filler Pad

Thermal

When it comes to thermally conductive gap filler pads, compromise is often the name of the game. That’s because historically, many products have provided either high performance or low material hardness, but not both features simultaneously.

Those days are over. We’re pleased to introduce THERM-A-GAP™ PAD 80, the highest performing gap pad from Parker Chomerics. This pad has a thermal conductivity of 8.3 W/m-K, much higher than the 3-5 W/m-K range commonly seen in thermal pads these days. It is perfectly suited for applications where high temperatures are likely and performance can’t be scarified, providing superior heat transfer across a range of thicknesses while maintaining low compression forces and conformability between mating surfaces.

What Makes Fiber Optic Cables Immune to Electromagnetic Interference?

EMI Shielding / Telecom/IT

There are a number of tools at our disposal to ward off the damaging impacts of electromagnetic interference (EMI), including fiber optic cable. Learn why fiber optic cable is immune to EMI and how adding reliable EMI shielding products can lead to even better electronic device performance.

The Basics: How to Prevent, Stop, and Reduce Electromagnetic Interference

EMI Shielding

When it comes to mitigating the damaging impact of electromagnetic interference (EMI), device manufacturers should look at design considerations from multiple angles as early in the process as possible to avoid last-minute modifications, which can add unnecessary expense and delays. Learn more about how to reduce EMI and four areas engineers should examine as they consider how to prevent electromagnetic interference in products and devices.

What is an EMI Filter?

EMI Shielding

For the best defense against electromagnetic interference (EMI), an EMI filter can be used on top of other EMI shielding devices to provide additional protection for outputs and inputs and shore up any potential vulnerabilities. Learn more about how EMI filters work in conjunction with EMI shields to keep sensitive electronics performing at their best.

What is EMI Shielding?

EMI Shielding

Electromagnetic interference (EMI) – unwanted noise or interference in an electrical circuit that can degrade or even halt system performance – is an important product design consideration that impacts every industry. Learn more about what causes EMI and how EMI shielding can protect electronic devices and machinery from its damage.

Safeguarding Alternative Energy with Engineering Innovation

Thermal / Alternative Energy

Around the world, businesses and consumers alike are turning their attention to alternative energy sources such as solar, wind and hydropower. These eco-friendly options provide a number of attractive benefits, including the opportunity to:

- Reduce carbon emissions.

- Stabilize energy costs instead of constantly adjusting to fluctuating oil prices.

- Improve an organization’s reputation while demonstrating corporate social responsibility.

This growing interest isn’t just hype; it’s backed by large investments in green, sustainable energy, and many companies are hard at work developing a broad suite of innovative products to meet the demand.

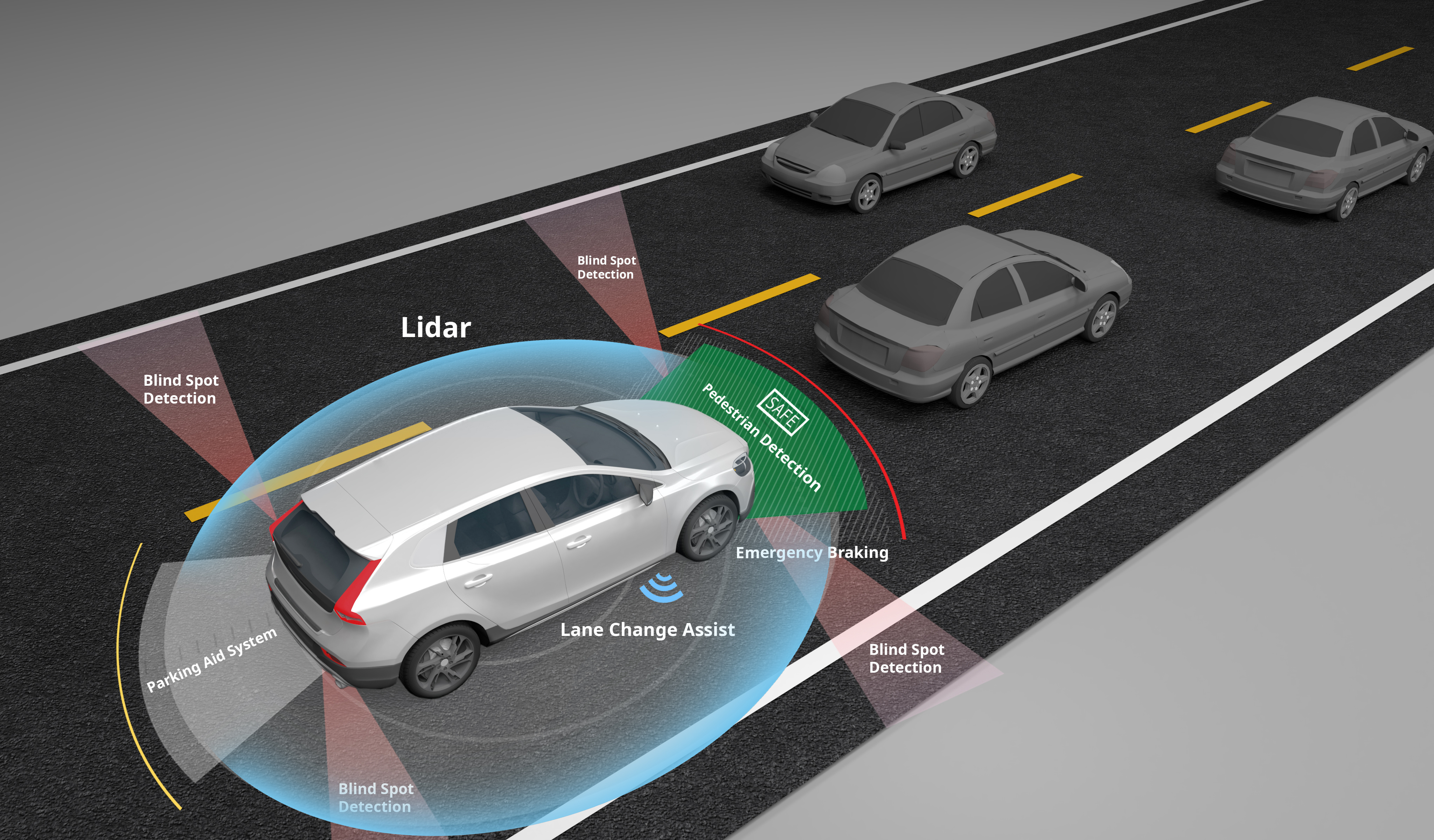

What is ADAS?

EMI Shielding / Thermal / Automotive / EV

The modern car driving experience has evolved significantly in both safety and convenience, thanks to technology innovations in advanced driver-assistance systems (ADAS). Using a human-machine interface that helps drivers anticipate and react to potential hazards, the early warnings and automated systems built into these electronic technologies aim to prevent car accidents or minimize the impact of those that can’t be avoided.

ADAS is widely available; these systems are built standard to most modern vehicles, and individual features and even entire systems can be added after market in many cases.

Reduce EMI With Enhanced Board Level Shielding Components

EMI Shielding / Thermal / Automotive / EV

Introducing Parker Chomerics RF Shields and Cans. These BLS components are the optimal solution for reducing or limiting the effect of EMI on printed circuit boards. This has been a popular request from our customers, and we’re delighted to offer a solution.

Developed based on decades of expertise in EMI and RF shielding, precision metal forming, and state- of-the-art manufacturing practices, Parker Chomerics BLS components are designed and manufactured to help provide isolation of board level components, minimize crosstalk, and reduce EMI susceptibility, all without impacting system performance.

From Fitness Trackers to Medical Monitors: Wearable Health Technologies Are Getting Smaller

EMI Shielding / Thermal / Life Science

Miniaturization presents significant challenges for engineers as devices become smaller, the number of functions per device grows and power increases.

Parker Hannifin is helping manufacturers meet the challenges of engineering in these small requirements, providing solutions in two areas on opposite ends of the spectrum: electromagnetic materials interference (EMI) and grounding, and thermal interface material (TIM).

Reliably Improve Application Performance With THERM-A-GAP GEL 20

Thermal / Automotive / EV

Parker Chomerics THERM-A-GAP™ GEL 20 is a moderate-performance, one component, dispensable thermal interface material with 2.4 W/m-K thermal conductivity developed to conduct heat from electronics to a heat sink or enclosure. It is specifically formulated to accommodate today’s high reliability requirements for thermal cycling and high temperature environments.

EMI Shielding and Thermal Solutions for High Frequency 5G Applications

EMI Shielding / Telecom/IT

Major telecom providers are working hard to overcome a range of technical challenges to deliver on 5G’s potential. One of the outcomes of this work will be a higher number of components in more compact spaces, which in turn prompts the need for effective electromagnetic compatibility (EMC) and thermal management solutions.

Design Guidelines for Grounding, Shielding and Thermal Management in Wi-Fi 6E and Wi-Fi 7 Gateways

EMI Shielding / Telecom/IT

The last several years have seen an unprecedented leap in advancements of Wi-Fi technology. Three new generations have been adopted or developed in just a couple of years and with each improvement comes increased speeds, increased device capacity, and significant decreases in latency.

EMI Shielding and Thermal Interface Materials Optimized for Automotive

EMI Shielding / Thermal / Automotive / EV

EMI shielding and thermal interface materials are used in a range of automotive applications, including ADAS (advanced driver assistance systems), sensors based on RADAR (radio detection and ranging), LiDAR (light detection and ranging), and camera technologies. Other applications include ECUs (electronic control units), (DMS) driver monitoring systems, and car infotainment systems.

Parker Chomerics Protects Drones with EMI Shielding and Thermal Interface Materials

EMI Shielding / Thermal / Aerospace & Defense

Parker Chomerics has launched new solutions to protect drones from electromagnetic interference and overheating.

Drones operating near cell phone towers, buildings, antennae, high-voltage power lines and other obstacles can be affected by serious electromagnetic interference (EMI), compromising their performance and safety.

Top 5 Questions and Answers on Thermal Interface innovations for Consumer Electronics

EMI Shielding / Thermal / Automotive / EV

Parker Chomerics has been busy developing new, next-generation thermal interface materials specifically to help aid in the thermal cooling of consumer electronics devices. Successful thermal management of high-power electronic components (single chips, multi-chip modules, integrated circuits, etc.) with high heat dissipation ratings requires careful design engineering.

In this post, we’ll cover the top 5 questions you asked during our recent Thermal Interface Material Innovations for Consumer Electronics webinar.

New Conductive Elastomer Gasket CAD Models for Design Engineers

EMI Shielding

Over the years, Parker Chomerics has developed and enhanced virtually every aspect of conductive elastomer materials technology, from the earliest silver and silver-plated copper filled silicones, to the latest and more cost-effective nickel-plated aluminum and nickel-plated graphite composites.

New High Thermal Conductivity Gap Filler Pad for Smart Home Devices

Thermal / Consumer Electronics

Smart home devices are proliferating our everyday world, with popular products from both large multinational players and scrappy startups alike, there are endless smart home products available on the marketplace today.

From smart cameras to lightbulbs, plugs, door locks, speakers, virtual assistants, and streaming devices, every piece of technology in our homes is trending towards connectivity and will require thermal interface materials for device longevity and performance.

This Is the Next Generation High Performing Thermal Gap Filler Pad

Thermal / Consumer Electronics

Looking for high thermal conductivity, yet ultra-soft thermal gap filler pad? Then you’ll want to take a close look at THERM-A-GAP PAD 60, the next generation of high-performing thermal gap filler pads from Parker Chomerics.

QSFP-DD Optical Transceiver Thermal Interface Materials

Thermal / Telecom/IT

High performance QSFP-DD optical modules must use thermal interface materials to help dissipate heat efficiently and effectively to ensure the optimum operating performance, reliability and dependability of the high-speed transceiver.

The introduction of QSFP-DD, or Quad Small Form Factor Pluggable Double Density optical modules, have now doubled of the number of high-speed electrical interfaces that the module supports compared with a standard QSFP28 module.

New THERM-A-GAP GEL 75 Thermal Gel Offers High Thermal Conductivity and Reliability

Thermal

Parker Chomerics has recently released THERM-A-GAP™ GEL 75, a 7.5 W/m-K thermal conductivity, single-component, dispensable thermal interface material. THERM-A-GAP GEL 75 is the latest from the THERM-A-GAP family of dispensable thermal materials from Parker Chomerics to be released to the market.

When applied to a heat-generating component, THERM-A-GAP GEL 75 provides minimal stress and pressure due to its low compression force. It is form stable in horizontal or vertical applications and allows for lower assembly costs when compared to multiple thermal gap pads in higher volume applications.

Top 8 Questions from Webinar Intro to Electrically Conductive Sealants and Adhesives

EMI Shielding

In our recent webinar about electrically conductive sealants and adhesives, our experts covered many topics from electrically conductive filler packages to the physical properties of the materials like adhesive strength, flexibility and working life. Did you miss Introduction to Electrically Conductive Sealants and Adhesives? Watch it now.

Overcoming Challenges of Fully Autonomous Vehicles

EMI Shielding / Automotive / EV

As the automotive industry moves toward more automated, connected vehicles, engineers are challenged to identify technologies that can process and transfer large volumes of data in real-time without adding significantly to the price of the vehicle.

EMI Shielding Honeycomb Air Vent Panel Design Features

EMI Shielding

Honeycomb air vent panels are used to help cool electronics with airflow and while maintaining electromagnetic interference (EM) shielding. Recently, our team of experts held a webinar on EMI shielding air vent panels, now available on-demand. This blog post will highlight some topics discussed in the webinar.

The most important factors of honeycomb air vent panels are shielding effectiveness and airflow, which are both directly related to the cell size. Both factors have a large impact on the size, material, and design of the vent panel. While you will need to balance the tradeoffs between airflow and EMI shielding needs, you should also ask yourself if air particle filtration is needed as well.

Vehicle Connectivity Drives Demand for EMI Shielding with High IP Rating

EMI Shielding / Automotive / EV

The growing connected vehicle and electric car markets are currently driving up demand for IP-rated (Ingress Protection rating) and EMI protection. Even standard road vehicle electronics need to be increasingly protected environmentally and electrically.

Vehicle functionality is being taken over by sophisticated electronics and these systems need protection against EMI and environmental elements such as dust, dirt, and water to operate efficiently.

Thermal Interface Materials for Challenging Private Spaceflight Applications

EMI Shielding / Aerospace & Defense

The advent of new and advanced technology has revolutionized the space industry, ushering in a new era of innovation and change brought by private space companies.

Parker Chomerics was recently honored by one customer for its engineering accomplishments in the development and application of its EMI shielding and thermal interface materials for challenging applications in private aerospace.

Selecting a Thermal Gel or Thermal Gap Pad – Your Questions Answered (Part I)

Thermal

The objective of thermal management programs in electronics packaging is the efficient removal of heat from the semiconductor junction to the ambient environment. While selecting a material for your application can be daunting, two of the most popular thermal interface materials you should consider are thermal gap filler pads and dispensed thermal gels.

In our recent webinar Selecting a Thermal Gel or Thermal Gap Pad, available on-demand, our team of thermal material engineers answered your top 14 most interesting and thought-provoking questions, starting with #14 below.

Selecting a Thermal Gel or Thermal Gap Pad – Your Questions Answered (Part II)

Thermal

The objective of thermal management programs in electronics packaging is the efficient removal of heat from the semiconductor junction to the ambient environment. While selecting a material for your application can be daunting, two of the most popular thermal interface materials you should consider are thermal gap filler pads and dispensed thermal gels.

You asked us a variety of interesting and thought-provoking questions during the webinar, which our team of thermal material engineers has answered below.

Need Better Flow Rate Control? Look to THERM-A-GAP GEL 37

Thermal

The demand for dispensing thermal interface material (TIM) has increased exponentially because dispensables offer engineers flexibility in the designs and patterns that can be applied to electronics packaging.

Single-component, dispensable TIMs such as THERM-A-GAP GELs, can cover a variety of gaps and form complex geometries which provide reduced thermal contact resistance, thus reducing the temperature and increasing the efficiency of the application.

Thermal Conductivity Measurement Frequently Asked Questions (FAQs)

Thermal

Over the years, we've taken many questions from customers just like you about the measurement and testing of our thermal interface materials. How are they used? How are measurements determined? What's the best way to characterize performance? So, we asked our engineers for help answering these questions. Read on to find out their answers.

Meeting NASA Low Outgassing Requirements in EMI Shielding Applications

EMI Shielding / Aerospace & Defense

Design factors for satellite, high altitude, and space-based applications vary dramatically from those of land or ship-based programs. These factors include: low payload capacity, low operating temperature, and meeting material limits.

Outgassing standards, established by NASA, set a limit on the release of gasses that can possibly interfere with sensitive technology within vacuum environments such as Low Earth Orbit (LEO). This is especially important for sensitive optical systems or camera lenses where the smallest bit of vapor or gaseous components can dramatically reduce performance.

Chomerics Earns GM Supplier Quality Excellence Award for 3rd Year

Plastics / Automotive / EV

We’re thrilled to announce the Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, has been awarded the prestigious 2019 GM Global Supplier Quality Excellence Award for its Engineered Plastic Solutions business unit in Fairport, NY.

What You Should Know About Electrically Conductive Elastomers

Elastomers / EMI Shielding

Electrically conductive elastomers are elastomeric polymers filled with metal particles. They can be grouped by filler type and elastomer type. Then within each of these classes, there are standard materials and specialty materials.

6 Tips When Selecting an Electrically Conductive Adhesive

Special Materials / EMI Shielding

There are many ways to improve the electrical continuity of electronic enclosures and the resultant EMC performance using a variety of electrically conductive gaskets and mechanical fasteners. Such arrangements have the advantage of being clean and easy to use as well as allowing for the equipment to be disassembled and the components replaced. So, ask the question: Is a compound the right solution in this particular case?

Five Things to Consider When Dispensing Form-In-Place EMI Gaskets and Thermal Gel

Thermal

Automated form-in-place (FIP) dispensing of EMI shielding gaskets can be ideal for complicated patterns on electronics housings because automation allows for control over the size and shape of the bead. In addition to form-in-place EMI gaskets, thermally conductive gels can also be automatically dispensed, and often span oddly shaped gaps and conform to complex geometries.

EMI Shielding and Thermal Interface Materials for Robot-Assisted Surgery

Thermal / EMI Shielding / Life Science

With proven solutions in EMI shielding and critical thermal management, Parker Chomerics gives you a wealth of integrated, multi technology systems and components that meet or exceed your specifications and expectations.

Meeting the Needs of Automotive OEMs with Collaborative Engineering Innovation

Plastics / Automotive / EV

Parker Hannifin collaborated across business units to develop access port covers for EV cooling systems that are manufactured from high-precision, injection-molded plastic. This value-added, integrated solution leverages two different Parker technologies to bring top-tier original equipment manufacturers (OEMs) an innovative and proven solution.

EMI Shielding Technology Applications in Defense Systems

EMI Shielding / Aerospace & Defense

As the defense industry continues to push the boundaries on advanced electronic systems and state-of-the-art communication devices, the requirements governing these programs must follow suit. Among the many technical requirements is Electromagnetic Compatibility, defined as the ability of a device to withstand both anticipated and unanticipated electronic interference (EMI) as well as minimize the interference being radiated.

EMI Testing for Medical Devices – What You Need to Know

EMI Shielding / Aerospace & Defense

Medical devices require complex analysis of the EMI/EMC regulations used for medical equipment and system certification. There are many new aspects that need to be addressed since medical devices are no longer used in just a hospital setting. With the increase of wearable medical tech, patients can theoretically be anywhere in the world. Therefore, EMI/EMC compliance testing needs to address the location of “end use” such as in the home healthcare environment and transportation considerations – trains, planes and automobiles.

Thermal Gels or Gap Filler Pads? Top 6 Things You Should Know

Thermal / Consumer Electronics

Two principal “gap filler” thermal interface materials prevalent on the market today are thermal gels – also known as dispensable gap fillers – and gap filler pads.

So, which one should you select for your application? Here are the top 6 things you need to know.

Protecting Robotic Surgery Systems from Electromagnetic Interference (EMI)

Thermal / EMI Shielding / Life Science

Robotic surgery systems or robot-assisted surgery, offer immense patient benefits -- from shorter recovery time to better surgeon visualization, which leads to a more precise, effective, and successful surgery. Robot systems are used for various surgical procedures, including urologic, gynecologic, cardiothoracic, general, and head and neck surgeries. Manufacturers and designers of these surgical systems are now focusing on robot specialization instead of all-encompassing surgical systems.

Form-In-Place Gaskets: What They Are and What They Are Not

EMI Shielding

Form-in-place EMI gaskets, also known as FIP EMI gaskets, is a robotically dispensed electromagnetic interference (EMI) shielding solution that is ideal for modern densely populated electronics packaging.

The most important distinction of form-in-place EMI gaskets is that they were developed for applications where inter-compartmental isolation is required to separate signal processing and/or signal generating functions.

New Thermal Gel Benefits Consumer and Automotive Applications

Thermal / Consumer Electronics

Careful management of thermal interfaces is crucial to maintaining the reliability and extending the life of electronic devices and equipment. As each new electronic product generation requires higher power in smaller packages, the challenges associated with thermal management become more and more intense.

THERM-A-GAP GEL45 is Parker Chomerics' latest high-performance, fully cured, dispensable thermal gel, designed for dispensing over heat-generating electronic modules to transfer the heat from the component.

6 Benefits of Overmolded Covers for Aerospace and Defense Applications

Thermal / Consumer Electronics

It's no surprise that electronic enclosures and housings in aerospace and defense applications are built to meet the most stringent of military standards. These include but are not limited to environmental stresses, EMI shielding, and maintenance requirements. Additionally, the advanced technological requirements of the devices requiring these enclosures mean that these devices must be more rugged and more powerful, as well as smaller, lighter, and easier to replace.

Why You Should Single-Source EMI Shielding Materials

Thermal / Telecom

EMI shielding of electronics using thermoplastic housings traditionally has been a complex and costly process. Today, OEMs not only have to meet the form, fit, and function requirements, but also must reduce the total cost of ownership, reduce weight, simplify the supply chain and reduce time-to-market.

Metal-to-Plastic Conversion Benefits for Automotive Engineers

Plastics / Automotive

For automotive engineers looking to reduce vehicle weight, metal-to-plastic conversion is a win-win. At the highest level, injection plastic molds are capable of producing multiples of millions of parts required for automotive programs with ease. Typically, a single tool can support a program for its entire life-cycle, meaning you only must go through the cost and design of tooling just once.

Five Ways to Maximize Performance of Electric Vehicle Batteries

Thermal / EMI Shielding / Plastics / Automotive / EV

Electric vehicles are developing fast in line with growing demand. However, only by selecting proven, reliable, high-quality products for the effective thermal management and EMI shielding of batteries, is it possible to maximize performance.

Best Conductive Plastics: Five Things to Look For

Plastics

Can electrically conductive plastics really replace traditional metal electronics enclosures? The answer is a resounding yes! There are very effective electrically conductive plastics available today that provide excellent electromechanical properties that help shield portable electronics from the electromagnetic interference (EMI) noise that is proliferating our daily life. Smart phones, Bluetooth, Wi-Fi, radio, even your television are all susceptible to EMI.

Improved EMI Shielding Consistency of Single Pellet Conductive Plastics

Plastics

For designers of electronics enclosures, conductive plastics offer the benefit of lighter weight coupled with cost effective injection molding. But for years, using traditional blended plastic pellet materials, the EMI shielding results were often inconsistent at best, leaving many engineers grasping for something better. There is a new single pellet alternative on the market, promising improved EMI shielding consistency, created using tightly controlled conductive material that delivers unparalleled EMI shielding performance and superior processing.

The Art of Spraying Electrically Conductive Paints

EMI Shielding

Electrically conductive coatings for plastic enclosure electromagnetic shielding are growing in popularity as concerns overweight increase for a variety of EMI applications in the military, aerospace, automotive, telecom, medical, and semiconductor marketplaces. These paints are filled with conductive metals such as silver, nickel, copper, or other specialty powders and flakes.

Conductive paints cannot be applied in the same way conventional paints are. Many first attempts do not go as well as planned. With proper preparation and practice, you will achieve success.

Design Decisions Relating to EMC Shielding

EMI Shielding

When approaching the problem of electromagnetic compatibility (EMC) the electronic design engineer quite often considers it to be a secondary issue that can be dealt with once the device is working and, after all, it can be dealt with by putting a metal box around it!

EMI Shielding Caulk Delivers Superior Performance in Military Radar Systems

EMI Shielding / Aerospace & Defense

Shielding for electromagnetic interference (EMI) is critical to military electronics systems operating in demanding environments requiring low emitted electronic signatures and protection from electromagnetic radiation. In mobile military applications, EMI shielding must be maintained during storage, transport and operation in a wide variety of demanding and corrosive environments.

The Benefits of Thermally Conductive, Fully Cured Dispensable Gel

Thermal

The use of Thermal Interface Materials (TIM) in high volume applications requiring low forces on components has evolved from hand applying greases and thermal pads to the high speed dispensing of 2-part cure in place systems. Most recently is the introduction of pre-cured one component gels. Automotive and electronics markets especially require greater throughput with reduced set up, change over, and increased application flexibility. Consumer expectations and warranties necessitate the use of high performance materials able to withstand extreme temperature cycling and shock and vibration environments.

EMI Shielding

There are many electromagnetic interference (EMI) shielding elastomer gasket mounting techniques that offer designers reliable, cost-effective choices in both materials and component assembly. These options offer aesthetic choices and accommodate packaging requirements such as tight spaces, weight limits, housing materials, and assembly costs. Most EMI shielding elastomer gaskets attach using easily repairable systems. Take a look at the list we've compiled of the seven most common elastomer EMI shielding gasket mounting systems below.

Top Three Design Tips for Corrosion Resistant EMI Protection

EMI Shielding

Every design engineer should know that an EMI gasket must be installed between mating flanges to prevent electromagnetic radiation (EMI) from entering or leaving an electronic enclosure. But what if your equipment will be used in humid or tempest environments? How confident are you in your design that corrosion protection will be addressed? Not so much? Well, then read on. Here’s our top three design tips for ensuring corrosion resistant EMI protection.

Interesting New Developments in Commercial Aerospace Gaskets

EMI Shielding / Aerospace & Defense

What are the premium requirements of gaskets for flange-to-flange aerospace assemblies such as antennas, access panels, radars and lighting? Electrical conductivity? EMI (electromagnetic interference) shielding? Fluid and pressure sealing? Galvanic corrosion mitigation? In short, the answer is all of these things and more.

For this reason, designers choosing fully-cured, urethane-filled expanded aluminium gaskets will not only find a solution that meets all of these criteria, but one that offers numerous performance improvements when compared with alternative sealing solutions. In fact, users can expect a 33% lower total cost of ownership (TCO) resulting from the avoidance of assembly rework and material replacement.

Can Electrical Resistance Be Used to Predict Shielding Effectiveness?

EMI Shielding

Conductive elastomer EMI shielding gaskets use metallic particles to create a conductive path and shield enclosures from electromagnetic radiation. A key measurement of these gaskets is Electrical Volume Resistivity. Gaskets that have a lower DC resistivity generally indicate a more conductive particle. In many cases, this lower resistance / higher conductivity is associated with better levels of shielding effectiveness. This explains why gaskets with silver particles, which are very conductive, often out-perform gaskets with graphite particles. However, this is not always the case.

Managing EMI and Lightning Strike Protection in Today’s Aircraft

EMI Shielding / Special Materials / Aerospace & Defense

Composite materials have been replacing metal structures throughout the aircraft industry primarily to save weight, improve fuel economy and reduce costs. But the lack of electrical conductivity in these materials is a disadvantage when compared to the conventional metal airframes of the past. The conventional, metal airframe allowed designers to take advantage of the natural Faraday cage it formed to protect equipment against interference. There were many opportunities to ground items of equipment reliably by connecting directly to a convenient surface ground.

EMI and Environmental Sealing for Munitions Applications

EMI Shielding / Special Materials / Aerospace & Defense

Material selection for military applications requires careful consideration, as there are strict requirements to ensure maximum durability, security and of course performance. In munitions, or missiles and missile launch systems, materials that provide electromagnetic interference (EMI) shielding and environmental sealing are critical for the functionality and field life of the application.

Thermal Pads: Which Layer Do I Peel Off?

Thermal

Most thermal pads, also known as thermally conductive gap filler pads, thermal gap pads, or thermal gap filler pads, have many different layer materials or carrier substrate options to choose from. It can be confusing which layer is supposed to stay on the product and which layer gets peeled off and removed before application. In fact, it’s one of our customer’s most asked about questions and can cause a lot of confusion on the manufacturing floor.

5 Design Considerations for EMI and Weather Sealing Combination Gaskets

EMI Shielding / Metals / Aerospace & Defense

Combination electromagnetic interference (EMI) shielding and weather gaskets, more commonly known as EMI shielded combo strip gaskets, are an excellent choice for a variety of applications that require a resilient, highly conductive sealing solution of knitted wire mesh with the integration of an elastomer for weather sealing. Typical applications include electronics cabinet doors, telecommunication trailers, wing panel gaskets for the protection against lightning strikes, and EMP specified requirements and sealing of shipboard and EMI.

Discover a New Electrically Conductive Flame Retardant Plastic

EMI Shielding / Plastics / Automotive / Electric Vehicles

Electrically conductive plastics continue to provide reliable EMI shielding in a wide variety of applications. Specifically, thermoplastics can overtake bulky metal enclosures due to their superior weight, EMI shielding capabilities, and simpler manufacturing process. However, before purchasing any thermoplastic, it is important to consider performance capabilities.

Observations From the Electric & Hybrid Vehicle Technology Expo North America

EMI Shielding / Thermal / Automotive / Electric Vehicles

Another Electric & Hybrid Vehicle Tech Expo North America has concluded and it is evident that this show has grown by leaps and bounds. In just a few years since Parker Hannifin has started exhibiting, the interest and demand in EVs and PHEVs have seemingly exploded, and the 2019 show proved to have the most suppliers and attendees the show has ever seen.

Parker Chomerics Earns 2018 Outstanding Quality Supplier Award from FCA

EMI Shielding / Plastics / Automotive / EV

We're thrilled to announce that the Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, has been recognized for its outstanding quality by global vehicle manufacturer Fiat Chrysler Automobiles (FCA) for both its production part and Mopar® unique parts partnership for the calendar year 2018.

This award, which specifically refers to Parker Chomerics Engineered Plastics Solutions business unit in Fairport, NY, has been awarded because of Parker Chomerics’ excellent performance as an FCA supplier.

Viscosity vs. Flow Rate - Which Is Best in Thermal Interface Materials?

Thermal

A common question often asked by our customers is the reason why flow rate is reported on datasheets of liquid-dispensed thermal interface materials instead of viscosity. And it’s a fair question; viscosity is a fundamental property of fluids such as thermally conductive pastes. But measuring viscosity, however, is more complicated than meets the eye.

How to Reduce Galvanic Corrosion Using Conductive Filler Systems

EMI Shielding / IT / Consumer Electronics

Galvanic corrosion (also known as bimetallic corrosion or dissimilar metal corrosion) is the breakdown of metallic surfaces as a result of the difference in electrical potential of adjacent metals and the presence of an electrolyte.

Electromagnetic Compatibility in Next Gen Autonomous Vehicles

EMI Shielding / General Industrial

or more than 100 years, the car has simply been used as a device for transporting a driver and passengers from point A to point B at speed with minimum effort.

With the introduction of Advanced Driver Assistance Systems (ADAS) and other semi-autonomous driving technologies, a different concept of the vehicle is emerging. In the future, the car will be a media playback center, telephone, office, and extension of the home’s living room which also happens to be able to convey passengers from A to B.

Honeycomb Air Ventilation Panels – The Polarity Principle

EMI Shielding / Telecom / Defense

Honeycomb air ventilation panels are used in applications where superior electromagnetic interference (EMI) shielding must be incorporated with heat dissipation in the form of airflow. Every vent panel has a variety of design features, each providing benefits to end customers based on specific application needs. These design features can include framing, plating/painting, gasketing, and vent size control.

Surface Preparation for Painting Conductive Coatings

EMI Shielding / Defense

Did you know that up to 80% of conductive coating failures can be directly attributed to inadequate surface preparation? Not properly preparing your surfaces for spraying or adherence is almost certainly the best way to set yourself up for failure. And on top of that, many different surfaces require vastly different preparations – it’s hard to keep up with which goes with which!

The Four Best Thermal Interface Materials For Cooling Electronics

Thermal

The world of thermal interface materials continues to evolve as the cooling requirements for applications in the automotive, consumer, medical, and aerospace markets continue to demand lower prices and higher performance. As each new product generation requires higher power in smaller packages the challenges associated with thermal management become more intense.

What Are Electromagnetic Interference and Electromagnetic Compatibility Measurements, and Why Do We Care?

EMI Shielding

Fundamental design checkpoints of new products generally focus on the designs of mechanical, electrical and software systems. On the whole, EMI/EMC design falls by the wayside for many companies, including preparation for certification testing.

How to Identify Quality Thermal Gap Fillers in Four Steps

Thermal / Telecom

There are a variety of thermal pads and gap fillers to choose from -- so many choices that it can become so overwhelming. How can you decide what's best for your application? And how does quality come into play? Read on, we answer these questions and much more.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.