CASE STUDY

Microwave Absorbers for ADAS Applications

Summary

Advanced driver-assistance systems (ADAS) have life-saving capabilities, but electromagnetic interference (EMI) from the high-performing components and diverse design requirements create an engineering challenge. CHO-MUTE™ 9005 and 9025 rise to the occasion, solving these problems with engineering genius by absorbing EMI radiation and ensuring data integrity.

Customer Challenge/Requirements

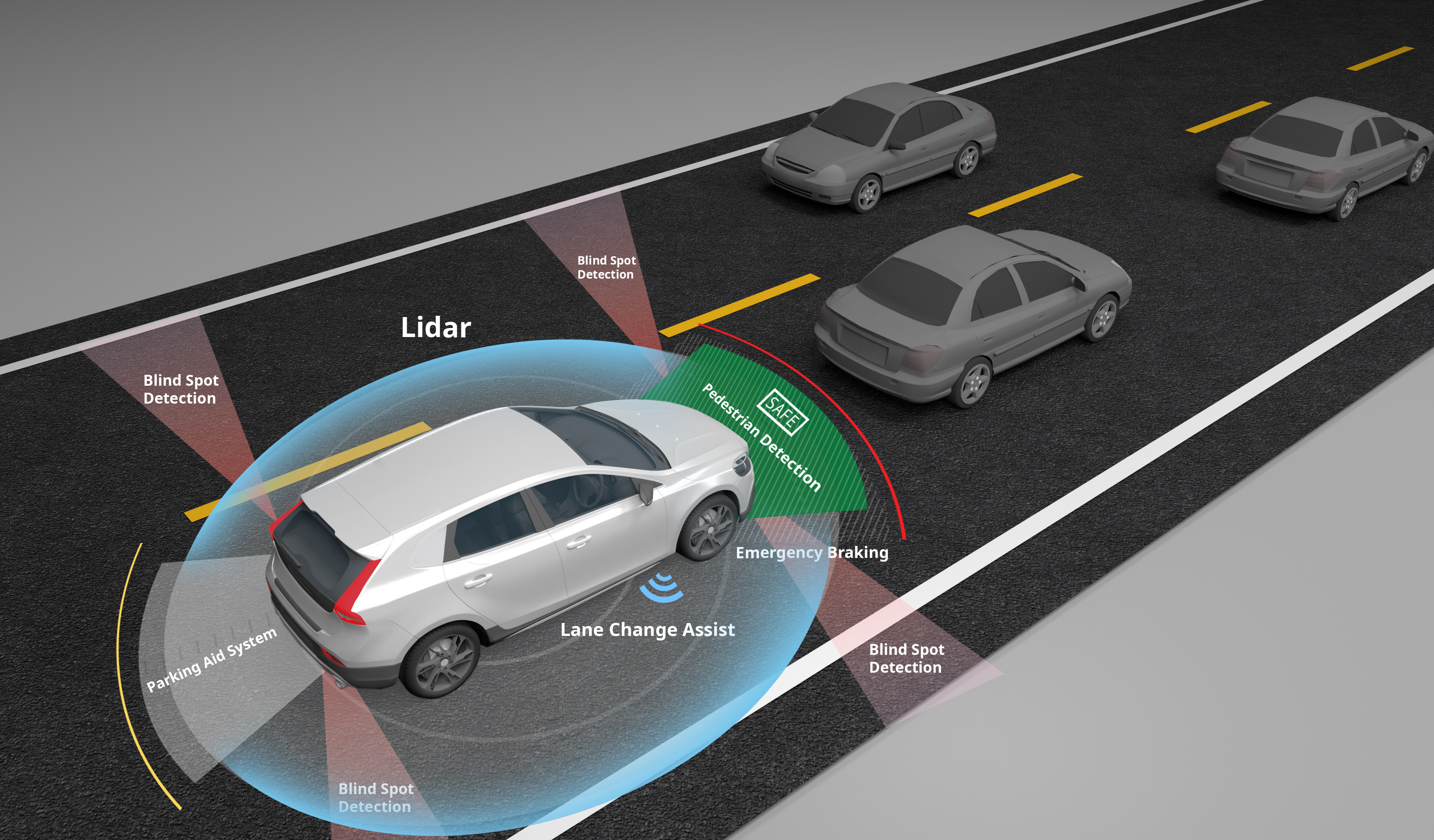

ADAS components, such as back-up cameras and lane detection warning systems, have become an important part of the modern driving experience. While this technology plays a key role in preventing accidents or reducing the severity of those that can’t be avoided, it also introduces many engineering challenges. Complex sensor and radar assemblies used in modern automobiles are subject to harsh electromagnetic interference from surrounding electronics, not to mention EMI radiation from the device itself! This latter source can cause data inaccuracies and decrease safety and reliability. EMI-shielding materials are an essential part of ensuring these systems function properly every single time. The materials utilized must be high-performing and flexible, as design requirements are usually vague and broad.

Design Requirements

Materials used for automotive EMI protection must be capable of protecting delicate sensors and electronics from challenging conditions. As devices become more and more powerful, the signals they emit can cause internal competition. Without proper management, this can cause improper working conditions that allow chips to interfere with other chips. The products utilized must prevent any kind of interference or resonance. And, these products must be flexible and customizable. Each automotive manufacturers’ specs will be different in terms of size, shape and thickness; engineers should always expect a manufacturing modification. While there are various options for EMI protection, absorbers are ideal for higher frequencies such as those found in automotive devices, and are designed to absorb electronic noise and protect sensitive devices and circuits.

Solution

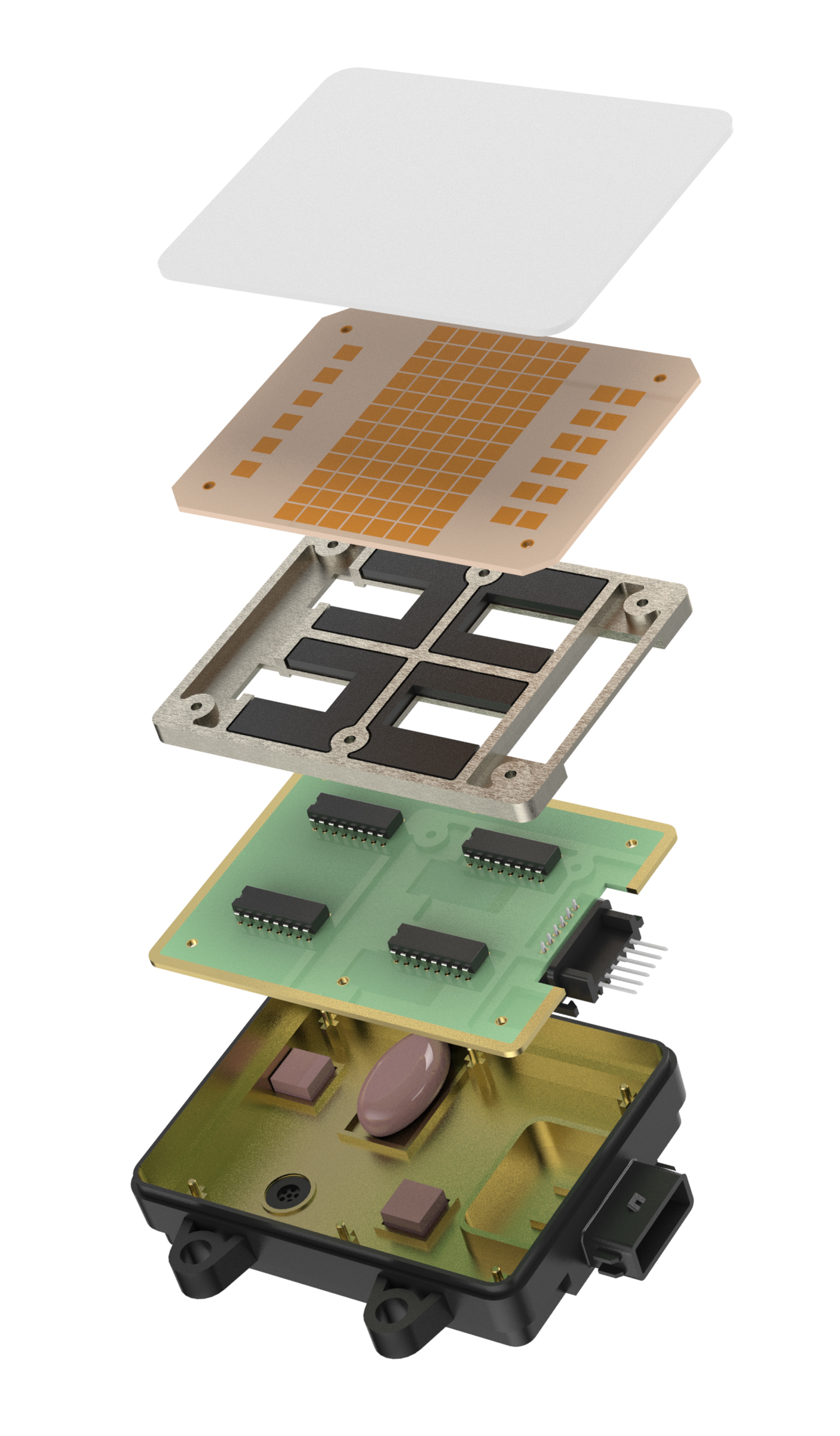

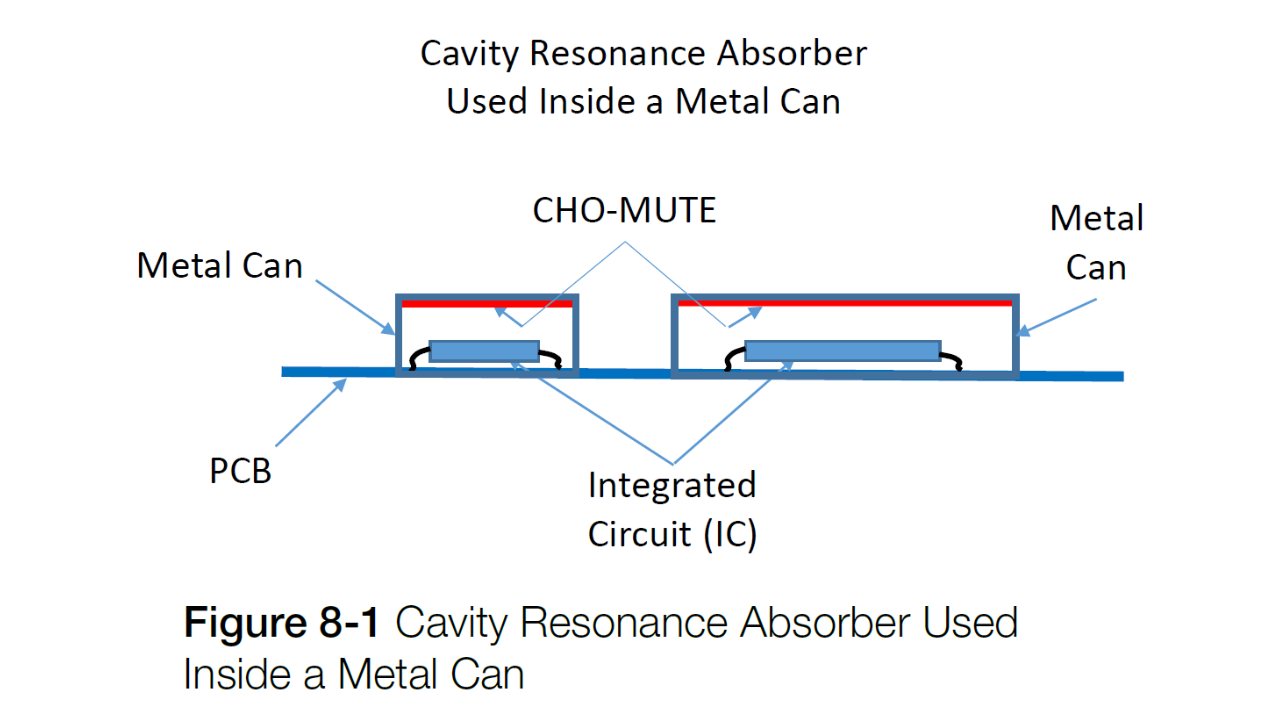

Parker Chomerics’ CHO-MUTE 9005, 9009 and 9025 offer customers performance as well as design flexibility. These elastomer-based absorber materials are designed to offer a user-friendly approach to the reduction of unwanted electromagnetic radiation from electronic equipment as well as minimize cavity-to-cavity cross coupling and microwave cavity resonances. Comprised of a silicone elastomer matrix with ferrous filler material, these materials provide RF absorption performance over a broadband frequency range from 500 MHz to 18 GHz.

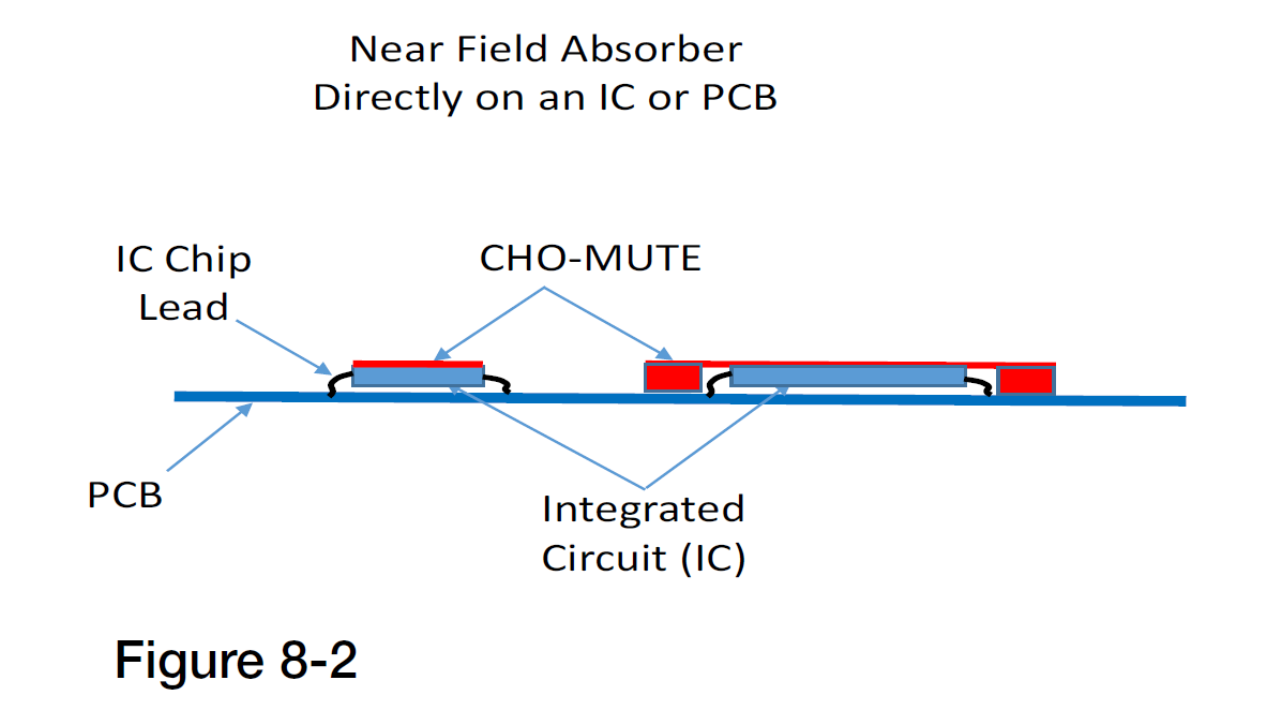

These absorbers are intended to be used in two ways:

- on top of EMI-radiating components

- in cavities containing components that are causing EMI disturbances

Both CHO-MUTE 9005, 9009 and 9025 offer many customization options to customers, allowing them to meet any engineering specification. The materials are offered as sheet stock of various thicknesses with or without pressure sensitive adhesive. They are flexible and can be easily die-cut for use in empirical testing of absorption solutions or assembled into cavities. Since both materials have been tested and certified to the UL 94 V-0 flammability standard, they may be used in close quarters with electronic circuitry to reduce unwanted electromagnetic radiation by absorption of signals and reduction of reflections from metallic surfaces. A wide variety of fabricating techniques are available for custom part manufacturing.

How to use CHO-MUTE microwave absorbers:

Results

According to the National Safety Council, ADAS could potentially prevent 20,841 deaths per year, or about 62% of total traffic deaths. With stakes this high, reliability becomes even more important. The systems must work effectively 100% of the time, as any failure in blind spot detection or adaptive cruise control could have tragic results.

Like all Parker Chomerics engineering innovations, CHO-MUTE 9005, 9009 and 9025 have been tested extensively and proven to perform.

For more information, see Parker Chomerics’ Conductive Elastomer Engineering Handbook, request a CHO-MUTE sample here, or contact a Chomerics application engineer here.

Microwave Absorber Materials

Parker Chomerics CHO-MUTE 9005, 9009 and 9025 elastomer based absorber materials are designed to offer a user friendly approach to the reduction of unwanted electromagnetic radiation from electronic equipment as well as minimize cavity to cavity cross coupling, and microwave cavity resonances.

Solutions for ADAS

Advanced Driver Assistance System (ADAS) modules and infotainment panels have led the way in terms of advancement of electronic systems within passenger vehicles. Learn more about Parker Chomerics solutions for ADAS applications.

PROVEN PERFORMANCE

EMI shielding solutions for every application.

We're always striving to bring you the newest and best technology.

Integrated Assembly Required for Automotive Instrument Gauge Cluster

Discover three challenges a global automotive supplier faced when designing an integrated gauge cluster assembly on an aluminum die cast housing, delivered as a single assembly for instrument cluster module.

High Performing Thermal Interface Material Required for Automotive Safety Module Manufacturer

A global automotive supplier required a high performing, robotically dispensed, thermal interface material for an automotive ADAS module. After extensive testing and trials, it was determined that THERM-A-GAP GEL 45 was the best thermal interface material for the camera module.

This Is the Next Generation High Performing Thermal Gap Filler Pad

Looking for high thermal conductivity, yet ultra-soft thermal gap filler pad? Then you’ll want to take a close look at THERM-A-GAP PAD 60, which offers the enticing combination of both excellent thermal conductivity at 6.0 W/m-K, at a softness of 31 Shore 00. This makes THERM-A-GAP PAD 60 more than 40% softer than current-like-performance thermal gap pads from Parker Chomerics.

Read the blog →

INNOVATION FOR THE FUTURE

The best quality products to keep your automotive electronics cool.

CHO-MUTE 9005 and 9025 elastomer-based absorber materials are designed to offer a user-friendly approach to the reduction of unwanted electromagnetic radiation.

THERM-A-GAP GELs eliminate multiple thermal gap filler pad part sizes and their cross-linked gel structure provides superior long-term thermal stability and performance.

Electrically conductive fabric-over-foam gaskets provide a selection of commercial EMI gasket solutions suitable for most all indoor EMI shielding and grounding applications.