Introducing

THERM-A-GAP® CIP 35E

3.5 W/m-K Dispensable Thermal Cure-in-Place and Gap Filler Material

Parker Chomerics THERM-A-GAP CIP 35E is a two-component (2k) dispensable thermal gap filler and cure-in-place material with 3.5 W/m-K thermal conductivity. CIP 35E is designed to be an alternative to hard-curing dispensable materials but also provide an improvement over standard application methods associated with thermal gap filler pads.

As a two-component dispensable material, it has an excellent flow rate and can be dispensed in high volumes or used to fill in applications that require heat transfer in challenging geometries. Once cured, CIP 35E will act as a low hardness (50 Shore 00) gap pad, able to maintain effective contact without imparting compressive forces on surrounding electronics.

With a 1:1 mix ratio and packaged in cartridges of various sizes, this material can be easily dispensed through a static mixing tip using either manual or automated dispensing equipment.

Product Features

- Two-part (2k) dispensable material

- Cures to very low hardness (50 Shore 00)

- Good thermal performance (3.5 W/m-K)

- Excellent flow rate for high speed dispensing

- Conformable to irregular shapes

- No pre-mixing or weighing of components required

- Vibration dampening

Typical Applications

- Energy Storage Applications

- Power Electronics

- Consumer Electronics

- Commercial/Industrial Devices

Get a Free Sample of

THERM-A-GAP CIP 35E

Resources

Regulating Temperatures in Electric and Hybrid Vehicles: THERM-A-GAP CIP 35E

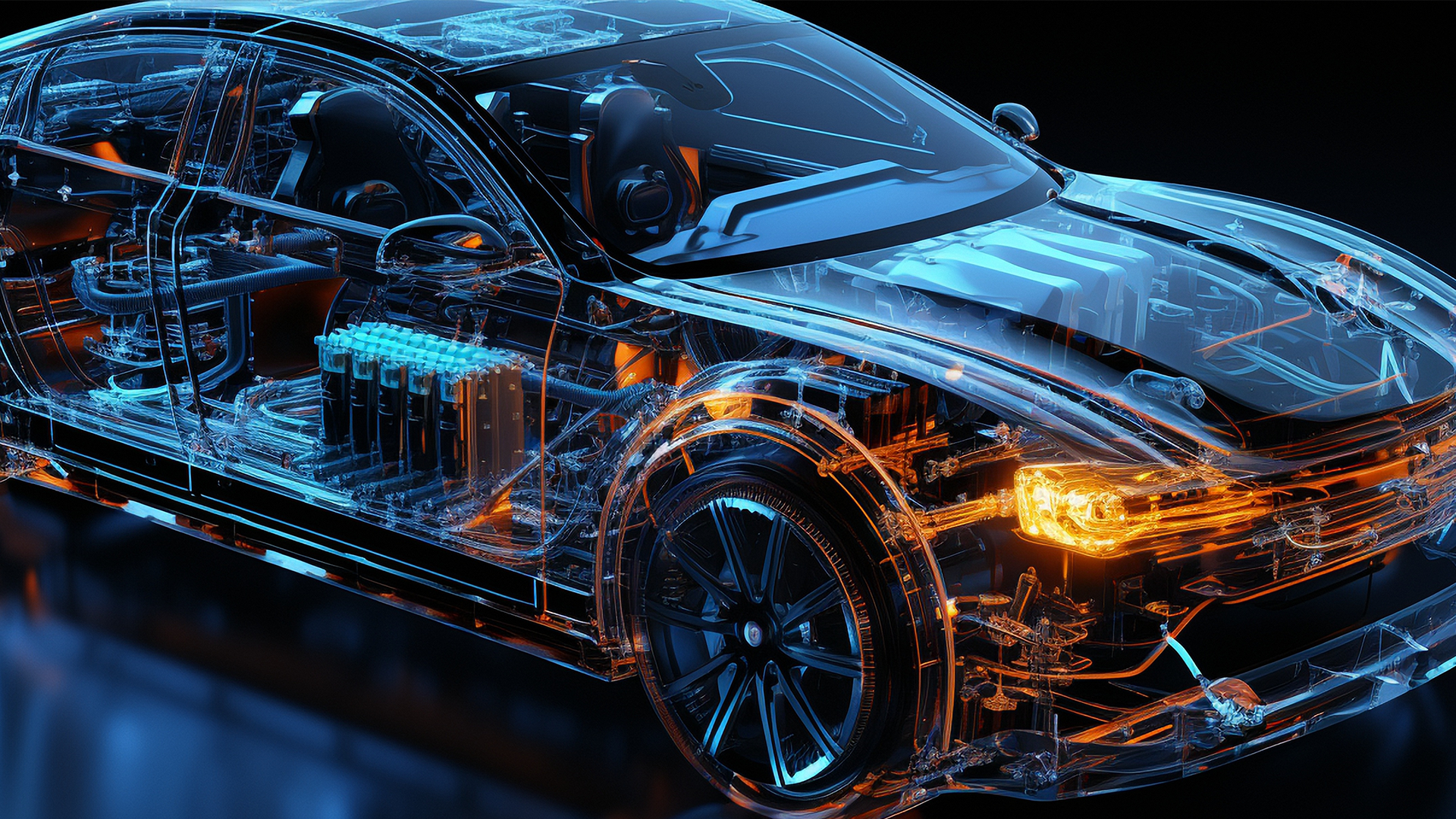

Electric vehicles (EVs) and hybrid vehicles (HEVs & PHEVs) are becoming increasingly prevalent to reduce the environmental detriments produced by traditional combustion engine (ICE) vehicles. The use of stored electrical energy as opposed to stored chemical energy (gas) requires the use of large battery packs to supply the electric drivetrain, and therefore the electric motors, with electrical power.

Selecting Between Thermal Gap Filler Pads and Thermal Gels

Discover the typical properties of thermal gap pads, also known as thermally conductive gap filler pads or simply just gap filler pads.

These soft, conformable pads are designed to reduce component stress and help with vibration dampening.

Different gap filler pads have different specifications depending on use of application, performance requirements, and much more. Watch the video to learn more about the properties of thermally conductive gap filler pads.

Embrace the Global Advantage in Manufacturing

EMC Considerations for Product Designers and Engineers

If you are a product designer or engineer who wants to know about the many solutions for electrmagnetic interference (EMI) shielding or simply wanted a refresher on the basics of EMC, this webinar is for you. You will learn the theory behind EMC, the products available to meet EMC regulations, the basics of testing for EMI/RF compliance, and hear about real-world application examples.

Can't find what you're looking for? Talk to one of our experts.