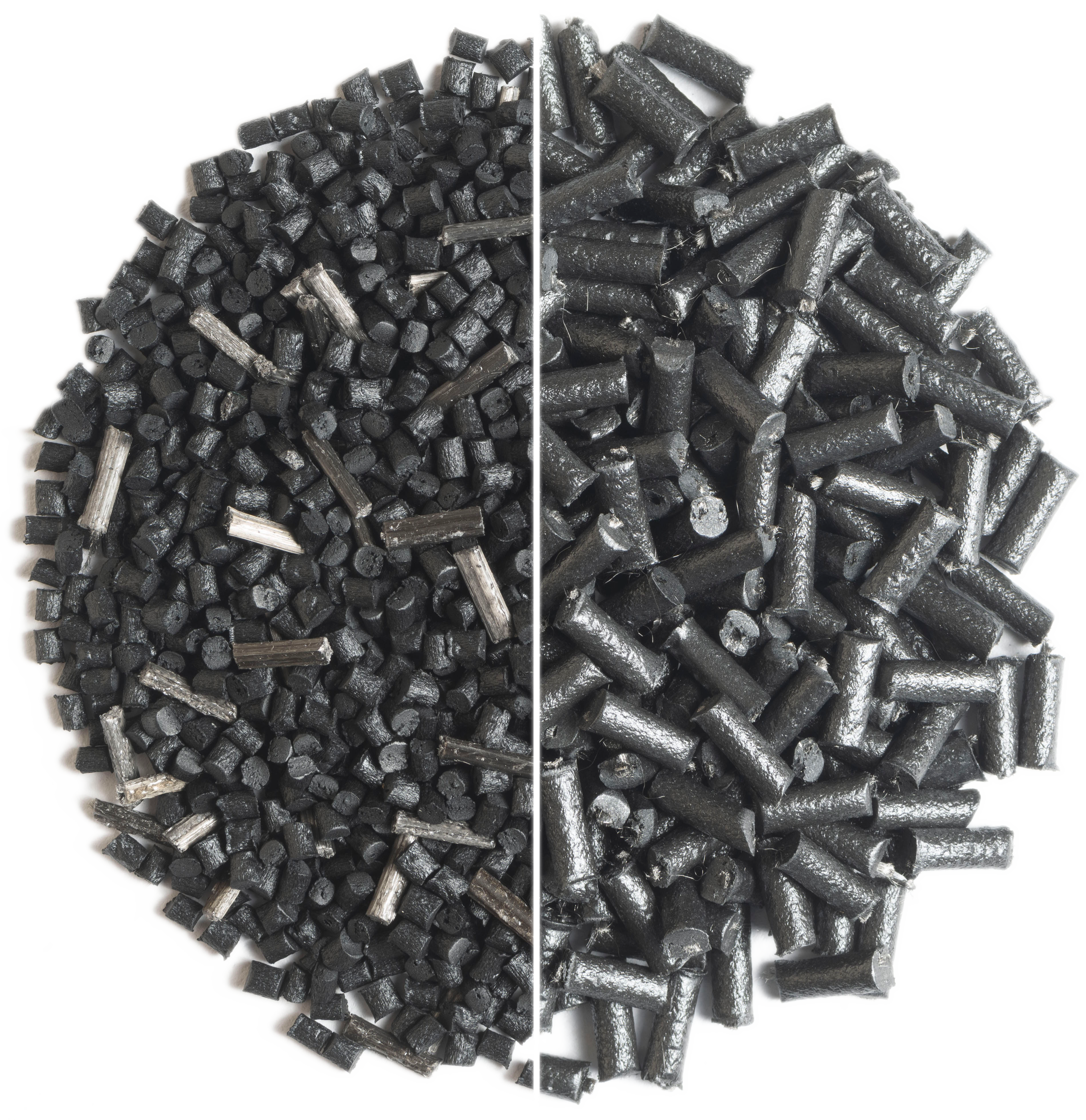

Our EMI shielding plastics come in a range of configurations to deliver high performance shielding.

Parker Chomerics' selection of EMI-shielding conductive plastic pellet materials includes conductive ATCA faceplate blanks; polyetherimide-based pellets for shielding, high-temperature performance, low smoke generation, and chemical resistance; PBT-based pellets for metal-to-plastic housing electronics conversions; and PC/ABS-based alloys to enable stable electrical, mechanical, and physical performance.

PREMIER Electrically Conductive Plastic

Parker Chomerics PREMIER electrically conductive plastics serve as a high performance, economical solution to EMI shielding and weight issues for automotive and life science markets

What is an EMI Shielding plastic?

Unlike normal plastics, electrically conductive plastics have the ability to conduct electricity -- providing “immunity” for sensitive components from incoming electromagnetic interference (EMI) and/or prevent excessive emissions of EMI to other susceptible equipment.

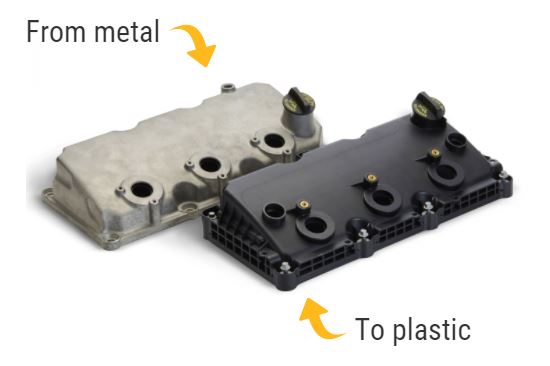

Product designers and engineers are discovering the unique advantages of electrically conductive plastics compared to traditional metals – such as weight reduction, cost reductions, elimination of secondary manufacturing steps – all resulting in leaner supply chains and better products.

Metal-to-Plastic Conversions for Automotive Applications

Metal-to-plastic conversion for automotive light weighting is quickly becoming an important characteristic as vehicles, especially EVs, try to improve emissions and range performance. This webinar discusses the benefits of using plastics your automotive application.

PROVEN PERFORMANCE

Quality EMI shielding where it matters most.

We continue to advance technologies to bring new and enhanced capabilities and efficiencies.

Electrically Conductive Plastics for EMI Shielding

Benefits, features, and advantages of electrically conductive plastics compared with metal parts or plastics sprayed with electronically conductive coatings. This webinar is approximately 30 minutes of presentation followed by a Q&A session.

Metal-To-Conductive Plastic Conversion for Major Radio Communications Manufacturer

A global manufacturer of radio communications equipment wished to replace an existing stamped metal housing with a lighter, more effective solution which would allow for access to the device for enhancements and repairs, without soldering.

Application of EMI Shielding, Conductive Plastics and Thermal Management Materials for ADAS Radar Sensor Modules

Join us for an exciting technical webinar as we discuss the benefits of metal-to-plastic conversion combined with integrated assembly manufacturing. Especially useful for automotive electronics housings such as those designed for advanced driver assistance systems (ADAS) like adaptive cruise control, lane departure warning, and blind spot monitoring.

INNOVATION FOR A SAFE AND SECURE FUTURE

The quality products you need that protect countries and civilians.

Parker Chomerics PREMIER™ PC-ABS Electrically Conductive Plastic - General Purpose grade is designed for general purpose use featuring a 85° C continuous temperature rating.

Parker Chomerics PREMIER™ PEI-140 Electrically Conductive Plastic is designed for high performance military applications, and is rated to UL 94 V-0 and features 170° C contunuous use temperature.

Parker Chomerics PREMIER™ PBT-250-FR Electrically Conductive Plastic - Flammability Rated grade is rated to UL 5VA and V-0, and is designed for fuel exposure and other fluid compatibility concerns