Diesel Engine Sealing Solution: Diamond Seal™ Technology Case Study

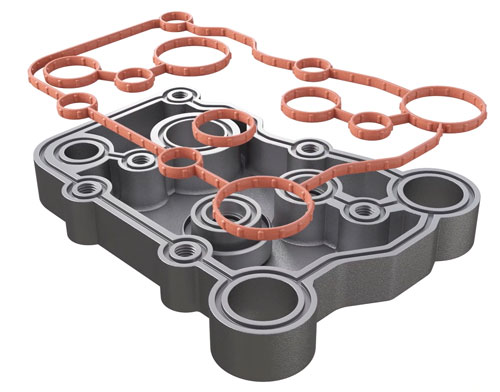

Sealing Challenge: Oil Cooler Module Redesign

As part of the development of a new light truck diesel engine, the oil cooler module was redesigned to capitalize on technology improvements. Our customer required sealing solutions for eight separate locations throughout the module. The seals needed to provide self-retention and withstand aggressive extended life coolant. The previous cooler module used silicone O-rings which provided limited durability in extended life coolants and required wide grooves.

Sealing Solution

Our engineers recommended Parker's Diamond Seal technology for all eight required seals, ranging from simple rings to complex geometries, sealing around multiple ports. Diamond Seals offers excellent sealing characteristics over a wide compression range while minimizing groove size for optimum packaging. EPDM rubber was used in coolant passages and fluorocarbon rubber was chosen for oil sealing duties. These Diamond Seals survived extreme durability tests including on-engine and 3,000 hour thermal cycle bench tests. Improved chemical resistance, sealing range, and self-retention distinguished the Diamond Seal from conventional sealing technology. By using this product, our customer was able to take advantage of reduced elastomer usage, increased design and packaging flexibility, as well as lower load and higher sealing pressure. This improved operator installation and safety, purchasing simplification, and reduced maintenance costs/downtime.

Parker Diamond Seals are used in a wide range of applications from electronics enclosures to engine seals to consumer products. Parker O-Ring & Engineered Seals Division offers custom seals that withstand a wide variety of environments, fluids, pressures, and temperatures. Contact us below and speak with an engineer via live chat or contact us at oesmailbox@parker.com for more information.

Diamond Seal Benefits

• High sealing pressure

• Combine multiple parts into 1 component

• Improved seal retention

• Easy installation and removal

• Low seal load

• Narrow-straight walled groove width requirement allows more room for other

components

• Optimal material usage

Common Applications Diamond Seals Are Used In:

• Cover seals

• Manifold seals

• Face seals with low to moderate system pressures

• Motorcycle fuel systems

• Diesel engines

• Fuel cells

• Military handheld radios

• RFID enclosures

• Portable dialysis equipment

LET'S DISCUSS YOUR APPLICATION. CONTACT US NOW.

Parker Hannifin Corporation

Engineered Materials Group

O-Ring & Engineered Seals Division

2360 Palumbo Drive, Lexington, KY 40509

859-269-2351