Webinar: Degradable Elastomers for Oil and Gas Downhole Completions

Hello and welcome to Parker's Tech Talk on degradable elastomers. My name is Nathan Sowder and I'm a business development engineer for Parker's O-ring and Engineered Seals Division, focusing on the oil and gas market.

Hi, I'm Jacob Ballard. I'm a R&D engineer of Parker O-Ring Engineered Seals Division focused on new compound development, including these degradable elastomers.

Before we get started today, just a few housekeeping notes, participants will be muted during the presentation. If you have a question during the presentation, please enter it into the Q&A feature in the Zoom panel and it will be answered at a later time. This webinar will be recorded and available for future listening. And also please fill out the survey at the end of the presentation to assist us with offering future topics that you may be interested in.

In today's tech talk, we'll be covering what is degradable technology, degradable versus dissolvable, an inside look at Parker's degradable elastomer offering, degradation characteristics of those materials and what products we are able to manufacture utilizing these compounds.

So to get started today, I think we should ask what is degradable technology? Degradable materials are those which break down over time in a predictable and desirable manner. This is a unique challenge for many manufacturers, as most are looking to design components to last long periods of time in service without showing signs of deterioration. A degradable material may serve as a solution if an application requires a temporary fix, which may be difficult or require significant expense to remove. Some arenas that utilize degradable materials today are the medical industry with dissolvable stitches and sutures, which can be used to eliminate a follow up visit to the doctor's office for removal.

As well, the oil and gas industry utilizes degradable and dissolvable components, mostly in the completion segment to help make oil and gas production more efficient. Jacob, can you give us a little bit better understanding on the differences between the terms degradable and dissolvable?

Thanks, Nathan. So we are often asked questions about the terms to and dissolvable and what is the difference. They get used interchangeably at times, so it can be somewhat confusing. So I wanted to be sure to clearly define them at the start. Typically, when we say dissolvable, we're referring to something that is chemically soluble in a solvent. For example, think of sugar or salt stirred into water. The solid material disappears, but the original substance is still present in the solution.

In contrast to degradable, materials undergo a chemical change when exposed to the right conditions. The original material is broken down or reduced in some way and changes form. This category includes biodegradable materials as well as the medical devices mentioned earlier, which are absorbed in the human body. The elastomers we'll be discussing today fall under this second category, as well, as degradable materials that chemically change when exposed to the right conditions.

Thanks, Jacob. So, as stated prior, one of the markets that utilize degradable and dissolvable materials is the oil and gas industry. This will be the primary market focus for today. There are several benefits of utilizing degradable materials in the oil and gas industry. We'll highlight a few here.

First, the use can simplify the process of extracting natural resources from the Earth. By using degradable components, oil and gas companies are able to remove an entire step from the well completion process by not having to return to drill out or clean out the well after frac. This, of course, results in a time savings, which can be on the scale of days to weeks. But it also results in an overall cost savings and increased rate of return by getting that well into production faster.

The use of degradable technology also reduces the human head count on a well site, which in return reduces the risk of a safety incident occurring. Another risk that is mitigated by the elimination of the drill out step is you aren't able to get stuck downhole and result in massive downtime and cost, if that process isn't required.

And lastly, a benefit that can be seen is in environmental impact. Studies have been completed today showing that the use of degradable components to fully dress a well can eliminate that coil intervention step, which significantly decreases the carbon footprint of the operation. This is a benefit which is becoming more and more important with today's government regulations.

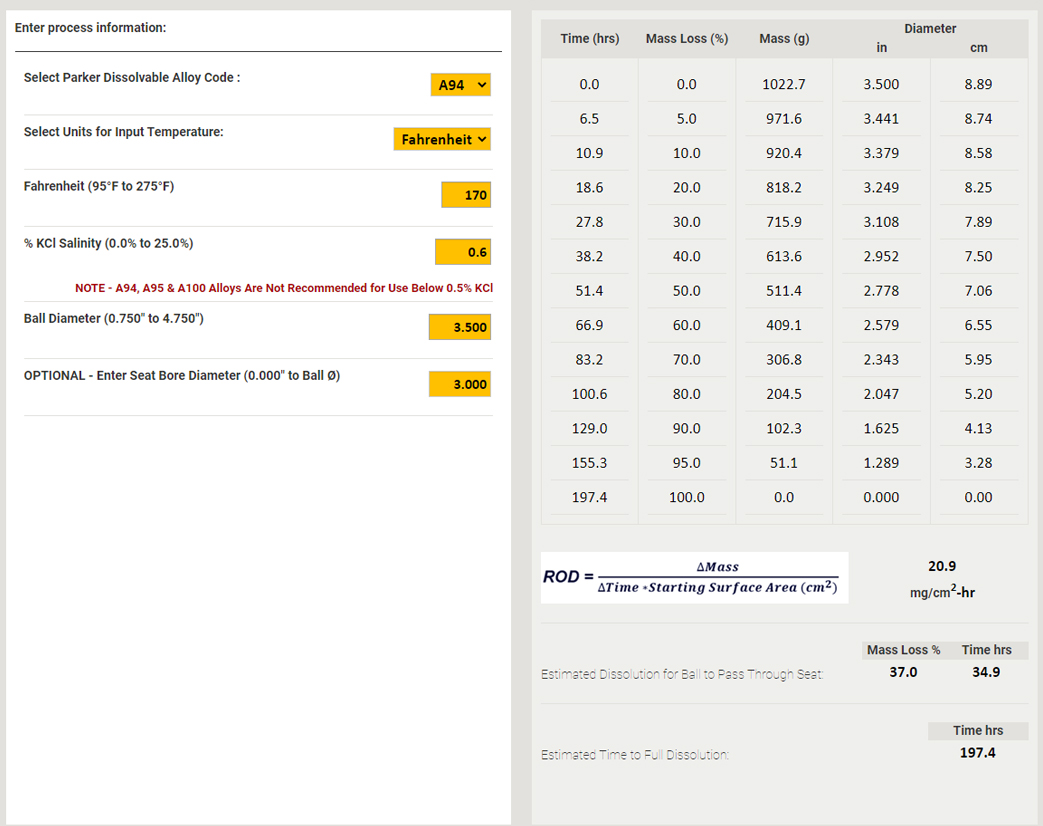

Some of the typical components in the oil and gas industry that are manufactured from degradable or dissolvable materials are hydraulic frac plugs. Traditionally, frac plugs were made from composites and then after the frac would be drilled out. However, the use of the degradable materials allow for the use of longer laterals, which were typically limited due to the inability to drill out those composite plugs at the toe of the well. Dissolvable frac balls are present, which can be used to actuate sliding sleeves or seal off certain stages of the well. Liner wipers are also used commonly to clean out the downhole casing from any debris which resulted from the drilling stage. Check valve seats can be used to limit flow between stages and also can benefit from degradable or dissolvable materials.

All of these components can be used with a mixture of materials, including dissolvable alloys, plastics and elastomers. But for today's discussion, we are only going to focus on the degradable elastomers.

When developing Parker's degradable elastomer offering, it was very important that we created a material which would have superior physical properties and stand up to the rigors of a typical oil and gas environment. These materials need to provide toughness and extrusion resistance; being able to run downhole and then seal pressures of 10,000 psi or greater.

It was also found to be very important for the elastomer to maintain flexibility and resilience, like traditional elastomers that have been use. This allows a packing element on a frac plug to set properly or a wiper fin on a liner wiper to properly perform its function. Parker's degradable elastomer fits both of those bills and is currently offered in both an 80 and a 90 Shore A hardness version.

The second part of the development was the trickiest. It was to make a material that not only performed well in high pressure applications without extruding or any damage occurring, but then also deteriorate after a period of time in various fluid composition across a wide variety of temperatures.

Parkers degradable elastomer is able to break down in both freshwater and brine solutions, with an ideal operating temperature range of 130 to 180 degrees Fahrenheit. Deterioration or degradation can be possible outside of this temperature range, although it may be shorter or longer periods of time.

Lastly, it was very important that after breaking down, the materials produced flowable, non-clogging particulates which could be flowed back without causing any issues in service. That is what is being shown in the images to the right of the slide. Here we have a vial with particulates that have resulted from the aging of a degradable elastomer in fluid. You will notice that these particles are small enough that they are able to be drawn up into a pipette. We believe that particles that are able to flow and are of this size should not cause any issues with filters or screens that could be present in the flowback process. Now I'm going to pass it back to Jacob, who will talk a little bit more in depth and with some test data regarding physical and degradation properties of Parker's degradable elastomer materials.

Thanks, Nathan. Over the next few slides, I'll cover some representative data to illustrate the properties and performance of our degradable elastomers. Now, for simplicity, I'll be focusing on the 90 Shore A material ZP204-90. We do also have an 80 Shore material available ZP208-80, which behaves in much the same way and we do have data to share upon request.

As Nathan mentioned earlier, our goal was to develop materials that would meet the requirements of oil and gas completions with high pressure sealing.

So looking at the basic physical properties of ZP204, we have them compared here with a typical 90 Shore A Nitrile compound that you might find on a traditional composite frac plug. Comparing hardness, tensile strength and modulus, we can see that the degradable material ZP204 has about the same properties in the same neighborhood. Though we do not expect the degradable material to see regular use in hot air, we did also test compression set. And the value of 13% set shows that this is truly a elastomer material with resilience and does spring back even after that extended compression.

In order to quantify the potential for degradation, we also test the tensile properties of our materials after short term exposure to fluid. So in this case, test conditions were 160 degrees Fahrenheit and a 3% by mass solution of potassium chloride. This is used to represent typical completion fluid. After eight hours the test specimens were significantly softened and had lost the majority of their tensile properties. Though, as shown in the picture on the right, they were still maintaining their general shape and had not started to lose significant mass.

Of note, this test is mainly of use as a screening test to compare the degradation potentials of different materials under different conditions. The thin dumbbells with about 80 thousands of thickness are not necessarily a good representation of typical seals found in downhole tools. For that, we rely on testing of mass loss of a thicker, button shaped sample. So testing mass loss lets us make some estimate of how long it will take an element to completely degrade and leave the well free for production.

This basic procedure is immersing a button of the test material in an excess of fluid for a certain amount of time and then rinsing it on a quarter inch screen and measuring the mass retained on that screen. This procedure currently is in development by the Advanced Well Equipment Standards Group, which we have participated in, though it is currently still in the draft state. As shown here, our ZP204-90 compound loses about 50 percent of its mass after 19 hours at 200 degrees Fahrenheit. But once that specimen is dried out, the true mass loss is closer to 60 percent.

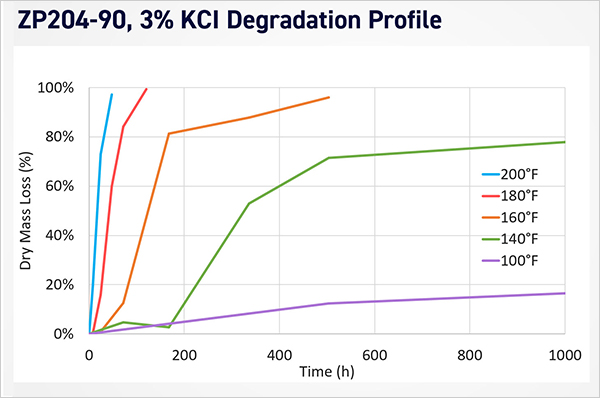

This procedure can be extended to multiple temperatures and times to produce a plot of degradation performance under a range of conditions. As shown here, temperature is very critical to driving the degradation. At 100 degrees Fahrenheit, after fully six weeks of degradation over 1000 hours, the specimen has lost very little mass. However, increasing the temperature to just 140 degrees Fahrenheit results in about 50 percent mass loss after two weeks; seventy-five percent after three weeks; and an eventual close to complete degradation. One important thing to note is that the un-degradable material, the material not passed through that screen-- is not unchanged or undegraded --is still very soft. It just is not able to pass through that 1/4 inch screen with the gentle rinsing.

To illustrate this, there's a series of pictures of the test specimens from the 160 degrees Fahrenheit test. So shown here the initial sample is again that standard button about 1/2 inch thick and an inch in diameter. After 24 hours in solution, it's grown softer on the exterior, but still is holding the general shape of the button and has not yet begun to lose mass. After 72 hours, parts of the surface are starting to separate from the main sample and there is a measurable loss in mass. The pieces on the left are very soft and probably could be passed through the screen with just a small amount of pressure. While the piece on the right, it is still somewhat hard in the center.

By one week, the entirety of the sample has become very soft and could easily be passed through the screen with pressure. This process continues over the next remaining weeks, though at a slower rate as pieces grow softer and it takes even less force, and just the act of rinsing is enough to pass them through the screen. This process continues with the last few pieces breaking down at a slower rate over the next few weeks. Shown here is two weeks and after three weeks, there is barely a measurable amount left.

One other important factor to consider is the effect of fluid chemistry. Shown here, we have a comparison of both freshwater and a 3% solution of potassium chloride, a 15% solution of hydrochloric acid, and diesel as a representative hydrocarbon. We can see from the tensile change that all these samples, with the exception of the diesel, do degrade in a short time. The general rule of thumb is that our degradable elastomers will react with any water-based fluid. They will not react with any hydrocarbon. They aren't strongly affected by the chloride concentration, and this trend continues up to at least 15 percent potassium chloride.

As further evidence of this mass loss is also very similar for distilled water, compared with 3% potassium chloride. Next, we have a short video showing the condition of a larger test specimen after exposure to160F fresh water for one week. At this point, the material is completely degraded and is very soft. The sample has retained some semblance of its original shape, but as you can see, it can be easily squished. Downhole, we would not expect it to obstruct tools or block flow back. Finally, Nathan will talk about some of the product offerings we have made from this material.

So now that we have highlighted a good spectrum of test data to support the performance envelope, we'll finish up with an overview of the products that Parker's Engineer Materials Group is able to manufacture utilizing this degradable elastomer technology.

Parker is able to process the degradable elastomer using all traditional manufacturing methods, including various molding techniques to create O-rings, custom molded shapes and packing elements. We are also able to extrude tubes and machine elements, which is great for production of intricate geometries or if there is a need to add features on the I.D. of the part.

Machining is also very beneficial for prototyping of low volumes of parts without having an additional tool charge. In combination with other divisions of Parker's Engineered Materials Group, we're also able to create bonded seals which use a combination of the degradable elastomer as well as the dissolvable alloys. So as you can see, Parker's Engineered Materials Group has a wide range of products available to help meet all of your oil and gas degradable needs.

Thank you for joining our presentation today. If you have any future questions, inquiries or requests pertaining to Parker's degradable elastomer technology, please contact myself, Nathan Sowder via the email, Nathanie.Sowder@parker.com, or my phone number (859) 335-2000, and we'll try to answer those for you quickly and as concisely as we can.

With that, we'll open up the live feed to any questions that may have arisen during the presentation. Once again, thanks for joining.

(End of recording)