- Valve installation and interchangeability

- Clockwise pressure adjustment (increase)

- Zero calibration required (Factory Set)

- Predictable and consistent performance

- High quality manufacturing

- Ability for OEM specific customization

- Global manufacturing, distribution, and support

- Extended system service life

- Extended brake motor life

- Reduced wear & life-cycle cost of operation

- Improved uptime

- Protection against overrunning loads and/or hose failures

What is a counterbalance valve?

Counterbalance valves are modulating, load control valves. Counterbalance valves are most typically used in applications that require load holding, critical metering control, controlling an overrunning load, or protection against hose failures. Additionally, these valves can be utilized as a brake control in hydraulic motor applications. ...

There are several functions/uses for this valve type:

Load Holding – Similar to PO checks, a counterbalance valve will hold a load in place. For example, preventing a cylinder from unwanted drifting.

Load Control – Counterbalance valves provide control for load motion. In the event of a runaway load, the valve will modulate the fluid flow and prevent further runaway which could lead to cavitation or equipment damage.

Load Safety – In the event of a hose or line break, the counterbalance valve will prevent uncontrolled and unsafe load motion.

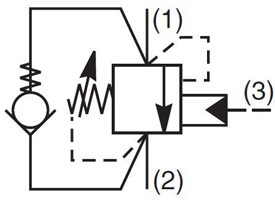

How does it work?

Pressure is developed at the work port of the holding valve when the actuator is pressurized. This pressure acts on the differential area, and the force generated is counteracted by the bias spring. When there is sufficient pressure present to overcome the spring setting, the poppet begins to shift, allowing fluid to pass through the valve port to tank via the control valve. ...

To assist in the shifting of the poppet, an external pressure source (generally the opposite side of the actuator) is connected to the pilot port of the counterbalance valve. This pressure is applied to the pilot area and assists in opening the valve. The pilot assist reduces load pressure required to open the valve and allows for a reduction in the horsepower required to move the load. If the load attempts to “run-away” (move faster than the pump can supply flow), the pilot signal will diminish, and the poppet will begin to close restricting flow to tank and thus controlling the load. The counterbalance poppet will maintain a position that keeps a positive pilot signal and will control the descent of the load.

When the flow is reversed to the actuator, pressure unseats the built-in bypass check portion of the counterbalance valve allowing flow to pass from the valve port to the work port. When no pressure is applied to either port of the counterbalance valve, the load is held in place.