Engineered Materials Group

Composite Sealing Systems Division

Edge-Bonded Gasket Sealing Technology

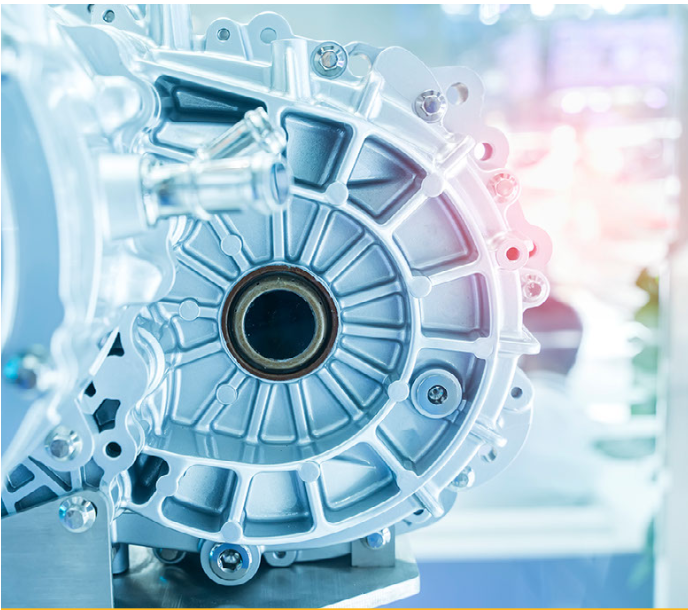

Integral Seal™ – Rigid carrier and molded-in-place rubber gasket seal solution

Fewer Components and More Design Possibilities

Parker has been improving productivity and providing freedom of design possibilities for over 65 years by helping OEMs reduce the complexity of component assemblies with composite bonded sealing technology.

Parker's one-piece, edge-bonded gasket solution Integral Seal™ is so named because it effectively integrates a rigid stamped or machined metal or molded retainer with a molded-in-place, vulcanized rubber sealing element.

What is an Integral Seal?

Sometimes referred to as a carrier seal or an edge-bonded gasket used to seal between static mating surfaces or flanges, the Integral Seal™ features a custom engineered rubber element that is edge-bonded and vulcanized to a rigid metal, plastic or composite carrier.

Solves Static Seal Challenges and More

Parker's bonded Integral Seal™ design technology not only helps design engineers overcome challenges commonly encountered with singular elastomer seals used in component assemblies, it provides significant improvements that:

- Simplify installation and maintenance by eliminating pinching, tearing, or crushing of seal element, plus there's no need for lubricant

- Provide visual confirmation the seal is installed

- Eliminate need for re-torquing

- Eliminate cost and necessity for groove machining in mating flanges

- Accommodate multiple materials and/or multi-port sealing on a single plate which also reduces potential for leakage from connected seal geometries

- Simplify procurement and inventory by reducing the number of single-piece parts

How Do You Select a Gasket Material?

Material selection of both the rigid carrier and sealing element is based on considerations that include:

- Media, or fluid which will come in contact with the seal

- Temperature, including operational and peak temperature values

- Pressure, taking into consideration minimum, maximum, proof, burst, cycle, pulsation

- Vibrational movement

- Thermal expansion

Common INTEGRAL SEAL™ Configurations

Whether mating surfaces are flat, curved, or have an irregular shape, composite bonded solutions can be designed to fit most any configuration.

Each customized solution is engineered with a precise squeeze or compression ratio of the elastomer to establish the optimal amount of intimate contact between the seal and the mating surfaces.

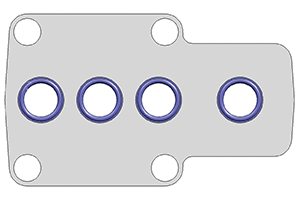

Single-Port or Multi-Port Sealing

There is virtually no limit to the number of ports, compartments or chambers that can be sealed with a single plate-like package to facilitate simple and foolproof installation. This greatly reduces assembly time and missing seals. Prerequisites include sufficient flange hardware, strength and adequate bolting pattern and force to assure plate seal and joint integrity during pressurization.

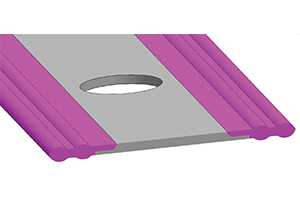

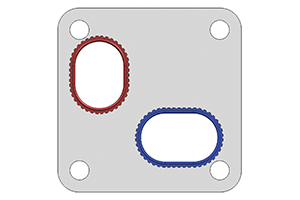

Tandem or Redundancy Seal

For “zero leakage” applications, a secondary companion groove and seal element parallel to the primary seal can be added. Note the leak-rate monitoring groove that can be provided between the two seals. The land width must be widened to accommodate dual seals.

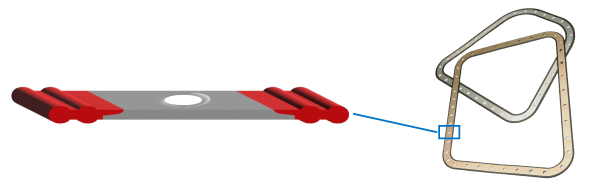

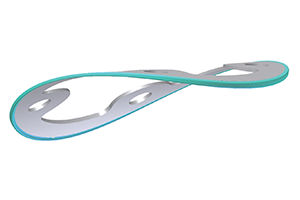

Contoured or Non-Planar Surface Seal

Parker currently designs and manufactures several Integral Seals used in contoured applications. When configured with a thin retainer, it's possible to bend the retainer during assembly and ensure intimate contact between two non-planar surfaces.This should be discussed in detail with CSS Division engineering department during the design phase.

Retrofit Seal

A retrofit Integral Seal can be designed for applications that have O-ring grooves in their hardware. It is extremely helpful in high pressure situations where the O-ring simply cannot handle the pressure or when the customer has a difficult time determining if there is a missing seal at the end of the assembly operation.

Segmented Seals

When an application requires customized gasket sealing for very large diameter assemblies, CSS can design segmented edge-bonded Integral Seal solutions that deliver reliable seal performance and reduce manufacturing and assembly costs.

Multiple Materials

Some applications require multiple materials for proper sealing. This may be due to chemical compatibility, permeation, or multiple ports with different fluids. Being able to incorporate different seal materials into the same retainer allows for optimization of the seal design vs. compromising with a single material selection. This feature should be discussed in detail with Composite Sealing Systems Division’s engineering department.

BONDED INTEGRAL SEAL™ SOLUTIONS, CATALOG, PRODUCT INFORMATION

Contact us to discuss bonded sealing solutions for your application.

Fill out the form below and one of our engineering associates will contact you.

©2022 Parker Hannifin Corporation

Engineered Materials Group

Composite Sealing Systems Division

Ph: 619-661-7000