RFID Technology

Patented Technology for Embedded RFID Tags

Discover the Unique Advantages & Robust, Built-In Protection of Embedded RFID Tags

Patented Technology for Embedded RFID Tags

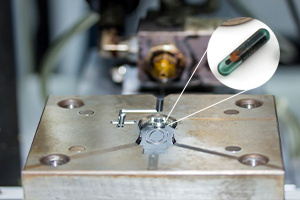

Using proprietary, patented and patent-pending techniques, Parker can embed a variety of RFID tags into a wide range of medical device component configurations. Parker has been particularly successful integrating RFID tags within thin walls or space-limited molded polymer components requiring only very small offsets from the part’s outer surfaces.

Complying with the FDA’s Unique Device Identifier Rule While Differentiating Your Products

Achieve compliance with the machine-readable requirement of the U.S. FDA’s Unique Device Identifier (UDI) Final Rule using Parker's proven, patented, techniques for embedding RFID tags into molded components during their fabrication.

Using embedded RFID tags for auto identification and data capture (AIDC) offers numerous additional opportunities for product enhancement and/or differentiation, including high level anti-counterfeiting characteristics, damage/tamper resistance and automatic parameter settings.

- No labels, adhesives or plugs to fail

- Tamper-resistant ID

- Extremely counterfeit resistant

- Covert in opaque materials

- No contaminant-harboring seams or manufacturing marks

- Equipment can automatically recognize components

- On-board tracking of device life cycles

Preventable Medical Errors Prompt U.S. FDA's UDI Rule

Preventable medical errors cause as many as 98,000 deaths each year. The U.S. Food and Drug Administration’s Unique Device Identifier (UDI) system aims to reduce medical device errors through:

- More rapid and precise identification of devices and their accompanying information/characteristics (e.g., expiration dates).

- Improved tracking of medical device use across all systems.

- Reduced counterfeiting and diversion of medical devices.

- Improved reporting of adverse events.

- Better management of medical device recalls.

- The development of a Global Unique Device Identification Database (GUDID).

UDI Requirements for Medical Device Manufacturers

All UDIs are issued by an FDA-accredited issuing agency, with each UDI having a unique numeric or alphanumeric code consisting of two parts:

(1) The device identifier (DI) is the fixed portion of a UDI that identifies:

- The labeler

- The manufacturer’s name, address and contact information

- The specific version or model of a device

- Product characteristics: for example, whether the product is single-use, sterile, latex-containing, etc.

- Clinic size and/or storage conditions

(2) The production identifier (PI) identifies characteristics of each unique (specific) device:

- Its manufacturing lot or batch number

- The device’s serial number

- Its expiration date

- Date of manufacture

- ID code for human tissue- based products regulated as a device

UDIs are not only required on the medical device but also its packaging, which can include device box, carton, case, etc.

UDI readability: Each Unique Device Identifier must be human- and machine-readable.

FDA Final UDI Rule is Now in Effect

Automatic exceptions include the following:

- Finished devices manufactured/labeled prior to compliance date. However, this exception automatically expires three years after compliance date.

- Class I devices exempt from Good Manufacturing Practice (GMP) requirements, e.g., a manual toothbrush.

- “…individual single-use devices that are distributed together in a particular package and are intended to be stored in that package and then removed from those packages for use do not need to have the UDI on the individual device itself. Rather, the UDI can go on the next higher level of packaging. And this applies for all classes of single-use devices.”6 This exception is not available for any implantable device.”

- Investigational devices or devices not intended for any clinical use, i.e., research, teaching or chemical analysis.

- Custom devices.

- Exported devices. Note, however, that The International Medical Device Regulators Forum (IMDRF) UDI Working Group (nations outside the U.S.) is working on a comparable UDI system.

Exceptions to the UDI Rule (§ 801.30)

Manufacturers must prove that a UDI for their device is technically unfeasible or possibly unsafe, or that they can better address the objectives of the UDI rule through alternative means. The FDA must approve the requested UDI exception or extension and may rescind it at any point.

Automatic Identification and Data Capture Technologies for Medical Devices and Instruments

The FDA UDI Final Rule states: “Automatic identification and data capture (AIDC) technology means any technology that conveys the UDI or the device identifier of a device in a form that can be entered into an electronic patient record or other computer system via an automated process.”

Why Choose Parker?

Experience. Expertise. Purpose.

- Leverage Parker's patented polymer fabrication technology for embedding RFID tags directly into your devices' plastic materials.

- Quickly re-engineer existing molded polymer components to include built-in RFID UDI technology.

- Jump start new product development by working directly with Parker from the earliest device concept to high-volume component production.

FAQs about Parker's Embedded RFID UDI

Q: Can the tags withstand gamma radiation sterilization?

A: Yes, gamma resistant tags can be utilized for many applications.

Q: Can the built-in RFID tags withstand repeated autoclave sterilization?

A: Yes. As long as the device and the material are designed to withstand autoclave cycles, the tags will as well.

Q: How small can the tag be?

A: RFID tags can be as small as a grain of sand. However, as you increase the tag’s data capacity and its read range, the tag, in general, increases in size.

Q: What are the data capacities of RFID tags?

A: As noted, the larger the tag, the greater the potential for increased information capacity. Parker can evaluate your storage needs against your device’s footprint and other requirements and provide advice on what is possible. Most applications will not required excessively large tags to accommodate their data storage requirements.

Q: Can the tags be written-to?

A: Yes.

Q: Can the data on the tags be locked? Encrypted?

A: Yes and yes.

Q: What are the read ranges for polymer-embedded RFID tags?

A: RFID read distances can range from near contact to 30+ feet. RFID read range is a function of the tag’s antenna size and the reader’s antenna size and power. “Active” RFID tags (i.e., with a battery) can have even longer ranges, but most medical device applications likely only need smaller “passive” tags that receive energy from the reader’s antenna.

Q: Does the embedded RFID tag make the medical device look different?

A: In general, no. However, it depends on the device: with opaque polymers, most patients won’t know about the built-in RFID tag unless they see it read by a healthcare worker. Parker has been very successful embedding RFID tags into small components without altering the size, form factor or appearance of the part.

Want more information about RFID Technology?

CONTACT PARKER

Learn more about the advantages and benefits of our embedded RFID technology and how it can help your next project. Talk with one of our application experts.

Parker Hannifin Corporation

Composite Sealing Systems

7664 Panasonic Way

San Diego, CA 92154

Ph: 619-661-7000

Parker Hannifin Corporation

O-Ring & Engineered Seals Division

2360 Palumbo Drive

Lexington, KY 40509

Ph: 859-269-2351

FOLLOW US