CASE STUDY

Meeting EMC Compliance and Managing Heat in Drones and UAVs

A leading drone and UAV manufacturer, specializing in a wide range of drone platforms required an EMI shielding and thermal interface material solution to meet EMC regulations as well as improve the performance and reliability of their products.

Drone Experiencing EMC Compatibility Issues and Overheating with Use

All drone equipment must comply to electromagnetic compatibility or EMC regulations when the product is released to the market. These regulations ensure the safe, secure, and sustainable use of drones.

As well as compliance, the drone’s electronic system was not working to its full potential and connection to the drone was inconsistent, prompting safety issues.

Drones Need Critical EMI Shielding Initiatives

Electromagnetic inference (EMI) within the drone’s electronic housing was causing system failure due to its operation near or around cell phone towers, buildings, antennae, high-voltage power lines and other obstacles. Communication from ground systems were causing serious electromagnetic interference, affecting the drone’s performance.

The drone’s electronics were also producing excess heat as a result of the high processing power and strong rotors, so our customer was searching for a thermal management solution that would help to improve reliability and prevent premature failure.

Drone EMI Shielding Design Requirements

- High shielding effectiveness was required to protect the internal electronics from malfunctioning.

- A faraday cage was required to shield the internal electronics from external electric fields.

- The electronic chipset processor required a better thermal solution to enable the drone to operate efficiently and not overheat after only a few minutes of use.

- The drone would be mass produced in large volumes, so manufacturing by automation would be beneficial to keep assembly costs down.

- The electronic housing was small and compact, so the size and weight of any materials added to the drone needed to be considered.

- The drone must operate effectively and safely. Connection from drone to controller should be consistent.

Key Specification Material Requirements

- A high shielding effectiveness of approx. 80 dB was required to prevent internal compartmental electric circuits from cross-talking.

- The solution should be small and lightweight as any extra weight on the drone would influence its performance.

- The drone will be exposed to a wide range of weather conditions such as rain or fog so the solution must be robust and corrosion resistant.

- The customer required any solution to be applied to the drone by automation to speed up time to market and keep costs down.

- Global manufacturing capabilities were required.

EMI Shielding Solution Developed by Parker Chomerics

The drone manufacturer’s design team and Parker Chomerics application engineers devised a solution that would help the drone pass testing methods for EMI/EMC susceptibility.

The design team needed to reduce EMF radiation levels as well as mitigate sources of external disturbances to harden the design.

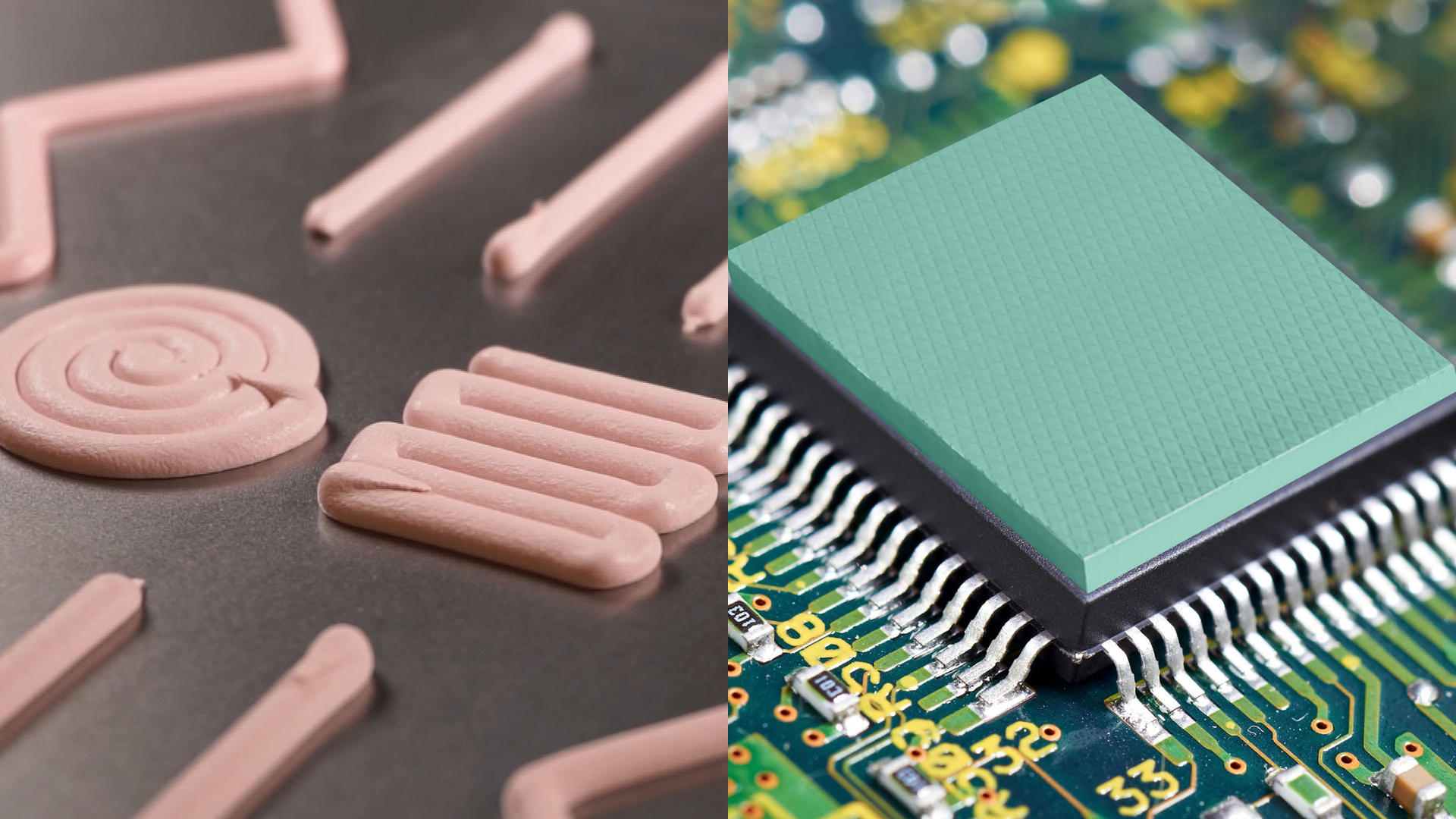

A robotically dispensed form-in-place (FIP) EMI gasket called CHOFORM® 5575 was directly dispensed onto the aluminum casting of the drone as a barrier to prevent the different electrical circuits from talking to each other and to prevent electronic failure of the drone. CHOFORM 5575 is a moisture cured silver-plated aluminum filled silicone offering up to 80 dB shielding effectiveness.

Using an FIP gasket saved 50% of space and weight in the housing as flanges can be as narrow as 0.025 in (0.76mm).

CHOFORM 5575 has a high resistance to corrosion when dispensed onto aluminum, so was selected to prevent galvanic corrosion in the electronic enclosure.

CHOFORM 5575

Parker Chomerics CHOFORM 5575 form-in-place EMI gasket is a moisture cure silicone system with 80 dB shielding effectiveness ideal for corrosion resistance in high temperature applications. Learn more.

Thermal Interface Material Solution Developed by Parker Chomerics

THERM-A-GAP™ GEL 37 (3.7 W/m-K thermal conductivity) was used to conduct the heat from the chipset to the enclosure. This pre-cured, single component thermal gel material was dispensed directly onto the chipset by automation, significantly reducing production time. GEL 37 has a soft, paste consistency which eliminates any stress on the electronic components and requires no mixing or curing.

Adding the EMI shielding and thermal solution to the device by automation improved productivity and reduced time to market.

Parker Chomerics global operations can offer local manufacturing in line with customer requirements, as well as provide application engineering and supply chain support

Our total assembly service can supply the metal castings, add EMI and thermal management solutions to the electronic housing or PCB, and supply as one complete unit. To learn more please contact us at www.parker.com/chomerics.

THERM-A-GAP GEL 37

Parker Chomerics THERM-A-GAP™ GEL 37 is a single-component, fully cured, dispensable thermal gel with 3.7 W/m-K Thermal Conductivity, designed for more consistent and repeatable dispensing by minimizing batch-to-batch flow rate variations. Learn more.

EMI Shielding Technology Applications in Defense Systems

As the defense industry continues to push the boundaries on advanced electronic systems and state-of-the-art communication devices, the requirements governing these programs must follow suit. Among the many technical requirements is Electromagnetic Compatibility, defined as the ability of a device to withstand both anticipated and unanticipated electronic interference (EMI) as well as minimize the interference being radiated.

Solutions for Thermal Interface Materials

Parker Chomerics thermal interface materials transfer heat from electronic components to heat sinks and are used to eliminate air gaps from the interface. Our THERM-A-GAP® materials deliver lower thermal impedance, higher thermal conductivity and greater compliance and conformability to both microelectronics and large scale electronics.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

Empowering Your Business on a Global Scale

Parker Chomerics’ manufacturing operations span the globe, allowing us to serve you locally no matter where you are. We understand your unique needs and provide personalized solutions that cater to your specific requirements.

Can't find what you're looking for? Talk to one of our experts.