SEALING SOLUTIONS

FOR FLUID POWER APPLICATIONS

Our expertise and complete fluid power seal product offering means Parker is your one source manufacturer and sealing solution partner. Parker‘s innovative technology and value added services allow us to engineer your success with leading edge material development, experienced design and application engineering, quality and outstanding customer service.

Featured Products

With in-house compound and design expertise, testing and process technology plus state-of-the-art manufacturing facilities Parker offers a wide portfolio ranging from standard products through to customized system developments.

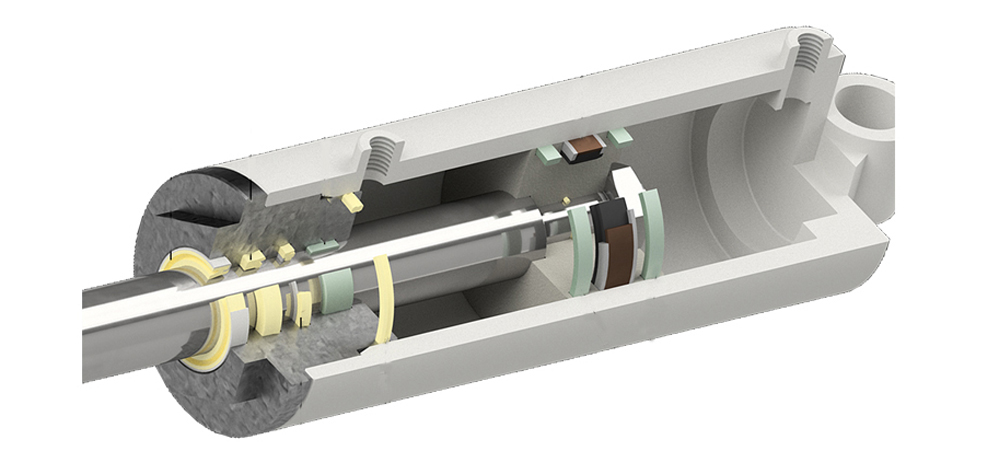

Zero Leak Rod Seal Package

Parker’s combination of advanced seal design technology and material expertise has produced a reliable Zero Leak Rod Sealing system for hydraulic cylinders for greater equipment output which maximizes equipment uptime by extending maintenance intervals.

Tight Tolerance Wear Rings

Parker’s tight tolerance wear rings in our 4778 material offer an internally lubricated surface, industry leading tolerances and best-in-class compressive modulus to resist side loading and prevent leakage and damage due to metal-to-metal contact.

Friction-optimized

Rod Seal HL

The “intelligent” HL rod seal improves the energy efficiency of hydraulic systems by combining a special functional principle and a friction-optimized material to ensure optimum friction, as well as sliding and sealing performance in all pressure conditions.

AV Wiper with Integrated “Dirt Shield”

The HS static radial seal exhibits a number of strengths versus the existing industry standard – the combination of an O-ring and back-up ring – for static sealing at high pressures.

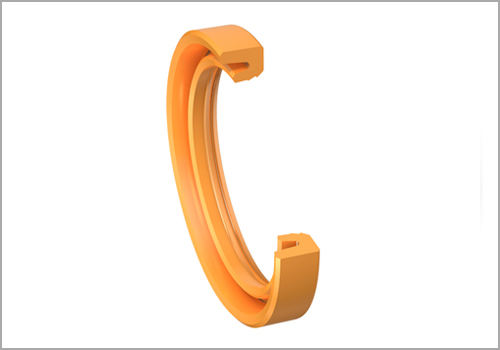

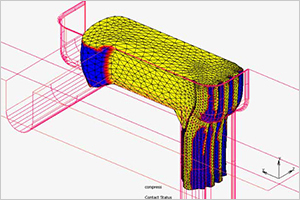

Press-in-place (PIP) Seals

Press-in-place (PIP) seal technology delivers excellent sealing characteristics over a wide compression range while minimizing groove size for optimum packaging.

Tube or Port Seals

Parker’s tight tolerance wear rings in our 4778 material offer an internally lubricated surface, industry leading tolerances and best-in-class compressive modulus to resist side loading and prevent leakage and damage due to metal-to-metal contact.

Air Duct Seals

Parker's Air Duct Seals for Heavy Duty Engines are a single piece, easy to install design, providing lower leak rates than traditional labyrinth piston ring seals.

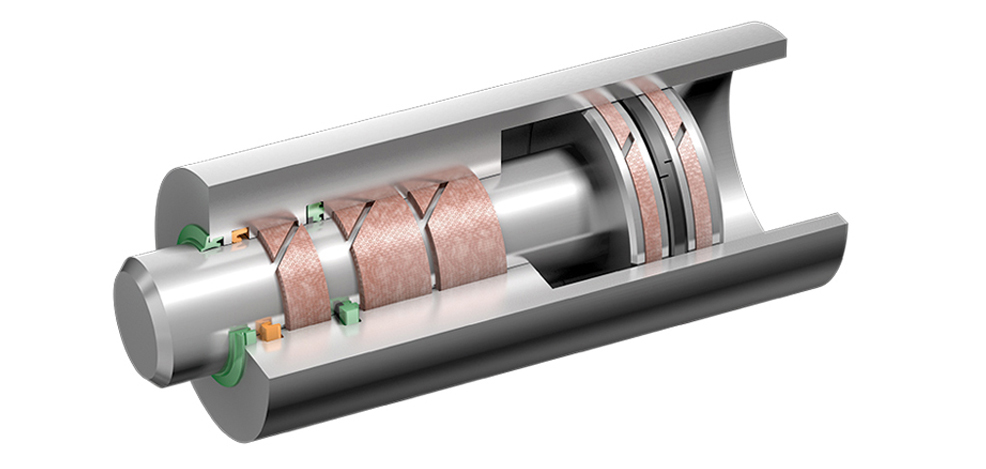

Unmatched strength and Heat Resistance - Fabric Reinforced Products

Parker’s fabric reinforced products offer industry-leading tensile strength, pliability and fire resistance in a low cost, durable elastomeric fabric composite.

Sealing Systems

By optimal pairing of seal design and material, the Parker sealing systems ensure that mobile construction equipment meets current and future demands in terms of loads, service life, ease of maintenance and eco-friendly operation.

Example: Sealing Systems for Wheel Loaders, Bulldozers & Backhoes

The individual seal designs in specified materials as well as the collective functions of all components in the sealing system shown ensure that cylinders used in earth moving equipment meet current and future demands in terms of loads, service life, ease of maintenance and efficient operation. Parker EPS Division's solution consists of the following components:

View Products

Example: Sealing System for Mini Excavators

By optimal pairing of seal design and material, the sealing system by Parker Prädifa ensures that mini excavators meet current and future demands in terms of loads, service life, ease of maintenance and eco-friendly operation. The solution is a tandem sealing consisting of the following components:

View our Product Catalog

Related Blog Posts

Seal T-Joints Without

RTV Silicone

New Sealing Solution Extends Service Life of Swivel Joints for Mobile Cranes

Innovative Heavy-Duty Vehicle Technology on Display at IFPE

Optimum Sealing Performance, Even in Low-Pressure Conditions With the HL Rod Seal

Support

You can also call us at (800) 854-5350 or request additional information about Parker materials and solutions for your fluid power applications using the button on the right.

Engineered Materials Group

© Parker Hannifin Corp 2019 I Privacy Policies