Electronics & Semiconductor | Webinars

Featured Webinars

Sipiol UV is a coating that cures with UV light in seconds and was developed for electric vehicle battery applications. This coating is electrically insulative and can eliminate the need for PET tapes. Attend this session for an overview of Sipiol UV product properties, applications, and performance data.

In this webinar you'll learn the requirements drinking water materials have to meet, how regulations differ in various countries and what solutions Parker Pradifa offers for global use of sealing systems.

Which factors influence the selection of the right seal for your application? In our webinar, you will gain insight into the wide variety of solutions and learn about the key factors influencing the selection of the right seal for your application.

Shock and vibration are remarkedly different; but do you know how those differences affect your MWD directional drilling? This webinar is focused on reviewing the principles, fundamentals, and challenges of shock and vibration in a downhole oil and gas environment. In greater detail, shock and vibration theory, mitigation, and solutions will be discussed about how to successfully protect the MWD tool string from shock and vibration. There will also be a brief overview of the Parker LORD family of downhole isolators.

It’s tempting to think of vibration isolation as a simple matter of putting a vibration mount between an object and whatever it’s resting on. Anything must be better than no mount at all, right? Actually, it’s not always right. In some cases you can create problems by adding a vibration mount to a system. Learn more about how vibration actually occurs and the basic compromises in implementing vibration isolation.

Join us for a discussion on design features of metal seal profiles and understand how base metals are enhanced with custom coatings to overcome sealing challenges.

Elastomeric seals provide the necessary barrier between your process and the environment. Leakage can occur when a seal is compromised, leading to unscheduled maintenance and costly downtime. At the worst, leakage can harm personnel or the environment. Identifying and preventing seal failure is critical to minimizing downtime and keeping the environment, health, and safety a top priority.

This webinar is a quick technical overview meant for engineers and covers topics including fillers and binders, housing design ideas, groove design basics, factors of corrosion and how to mitigate them and overmolded / vulcanized covers.

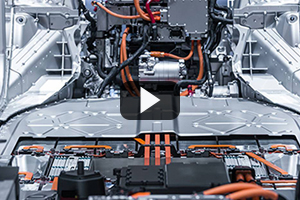

Traditional joining techniques in the automotive industry includes welding and mechanical fasteners. However, many challenges arise when using these methods. By using structural adhesives, the need for mechanical fasteners as well as post-weld rework is eliminated. Adhesives also eliminate heat-affected zones and can double as a sealant. In traditional fastening methods, mounting lugs, screws, and rivets pierce through the aluminum battery box, which can cause a potential leak point and risks potential for outside moisture to seep into the battery pack.

Automotive electronics require more power density and longer lifespans than in years past. Especially in electric vehicles, the increase of electronic components requires new design considerations, challenges and needs. As a total solutions provider, Parker LORD has a wide portfolio of thermal management materials, structural adhesives and coatings for automotive manufacturers and tier suppliers.

In traditional fastening methods, mounting lugs, screws, and rivets pierce through the aluminum battery box, which can cause a potential leak point and risks potential for outside moisture to seep into the battery pack. This presentation will dive into four top trends we’re seeing in the market for 2021 when it comes to thermal management solutions used in electric vehicle applications. Insights, data and real-world testing.

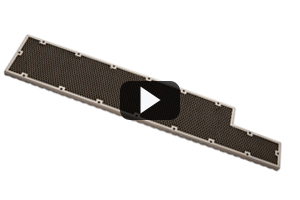

Discover the benefits of honeycomb EMI shielding air vent panels for airflow/dust and debris protection in this recent technical webinar.

The fast-growing electric vehicle market demands robust and efficient thermal management solutions for battery packs, such as gap fillers and thermal pads. Gap fillers outperform thermal pads to achieve lower thermal impedance, as the gap fillers conform to surface roughness before curing. This allows gap fillers to adhere well to surfaces and provide mechanical support during normal operation. However, this also poses a challenge during repair, removal and re-manufacturing. Currently, there is no set standard for measuring vertical pull-off, and hence, there is a lack of knowledge on what level of pull-off force is needed to service these battery packs.

Join our experts for an introduction in thermal management. We'll discuss the purpose of thermal management, why it is important, what components require it and when to consider it for your application.

Join our experts as we understand technical terms. We'll discuss an overview of technical terms used to describe thermal management products and talk through common electrical properties of cured and uncured materials.

Join our experts as we discuss silicone properties. We'll cover basic knowledge, how silicones interact, the difference between potting materials and gap fillers and what potential issues come about with material dispensing.

Join our experts as we discuss epoxy properties. Learn about epoxy properties and materials, when to choose an epoxy over different chemistries and the types offered for thermal management.

Join our experts as we discuss urethane and acrylic properties. We'll evaluate both chemistries, highlight coatings that can be paired to achieve dielectric protection and discuss Parker LORD's portfolio.

Learn more about electrically conductive plastics for EMI shielding, focusing on Metal to plastic conversion, how to pass that dreaded drop test, and light-weighting using electrically conductive plastics. Benefits, features, and advantages of electrically conductive plastics are compared with metal parts or plastics sprayed with electronically conductive coatings.

Electric vehicle batteries, much like traditional combustion engine batteries need to be repaired or replaced as they age. As EVs are designed and rolled off the production line using more innovative materials for assembly, it becomes more complex to remove or repair battery pack components. This webinar will address serviceability of electric vehicle battery packs and different methods for assembly.

What are electrically conductive coatings, and how do you choose a material? Our experts break it down in this technical webinar.

What are electrically conductive adhesives and sealants, and how do you choose a material? Our experts break it down in this recent technical webinar.

Discover the benefits of using electrically conductive materials to help limit galvanic corrosion in this technical webinar.

Which thermal interface material is best for your application? Our experts break it down in this technical webinar.

Metal-to-plastic conversion for automotive light weighting is quickly becoming an important characteristic as vehicles, especially EVs, try to improve emissions and range performance. Discover the benefits of metal-to-plastic replacement technology for automotive applications in this recent technical webinar.

What are electrically conductive form-in-place gaskets, and how do you choose a material? Our experts break it down in this technical webinar.

©Parker Hannifin Corporation | Privacy Policy