Problem Solved!

Application Success Stories

From initial concept to production, Parker's engineering teams support many of the world’s leading manufacturers in the ever changing trends of the industry, helping them to expand their geographical footprint and achieve optimal operational efficiency.

Fiber Optic Box Enclosure Seals

Today's environmental challenges require materials and sealing profiles to withstand harsh conditions. Parker O-Ring & Engineered Seals (OES) Division develops custom sealing solutions for the telecommunications market, providing UL94 V-0 listed materials and custom designed profiles.

Sealing Challenge:

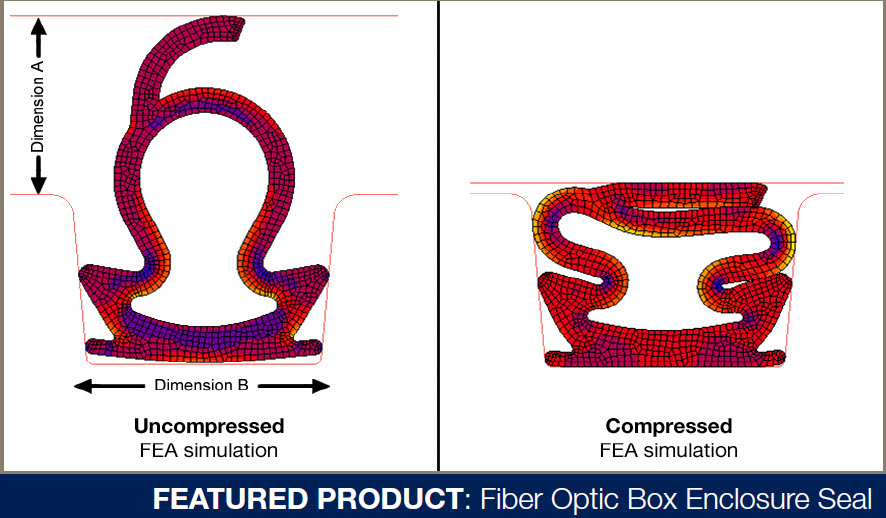

The fiber optic base stations of a telecommunications company experienced field failures due to foam seals that compressed after installation, resulting in leaks. These seals failed when exposed to temperature fluctuations, humidity, and fungal attacks, causing data outages for numerous customers. Parker was tasked with developing a seal capable of enduring this harsh environment while also filling spaces with varying dimensions (as shown in dimensions A and B) across different units.

Sealing Solution:

Parker O-Ring & Engineered Seals (OES) Division developed a custom sealing solution to meet the strict requirements of the customer. To begin, our application engineers chose a UL94 V-0 listed material that could withstand a wide temperature range and was fungus-resistant, making it an ideal choice for environmental sealing.

OES then modified the hollow D profile to accommodate the varying dimensions of the groove's width (dimension B) and the gap above the groove (dimension A). The hollow D design enabled the seal to fit flexibly in the groove with different dimensions. Additionally, our engineers added a "stem" on top of the geometry to accommodate a wide range of heights (dimension A).

The profile was extruded and spliced into 3-D gaskets using a hot vulcanization process to ensure high bond integrity. The final fabricated gasket had eight splice locations to provide a consistent profile behavior around the entire enclosure, retained within the groove during assembly, met the customer's requirements, and passed the wind-driven rain test. For further information or to discuss your project needs with a Parker engineer, please visit Parker OES.

Lastest OES On-Demand Webinar

Parker Fluorocarbon Materials for Extreme Temperatures

In today's demanding industrial landscape, O-rings and seals are facing unprecedented challenges in critical applications and environments where temperatures and pressures reach extreme levels. Industries such as aerospace and oil & gas are pushing the limits, requiring sealing solutions that can withstand these harsh conditions. Traditionally, fluorocarbon rubber has been the workhorse material for seals, known for its exceptional performance. However, it had one limitation - poor performance in low temperatures.

© 2023 Parker Hannifin Corporation

O-Ring & Engineered Seals Division

2360 Palumbo Drive

Lexington, KY 40509