FINDING THE RIGHT CONDUCTIVE ELASTOMER GASKET FOR YOUR APPLICATION

- Availability

- Design Flexibility

- Cost Effectiveness

- Proven Performance

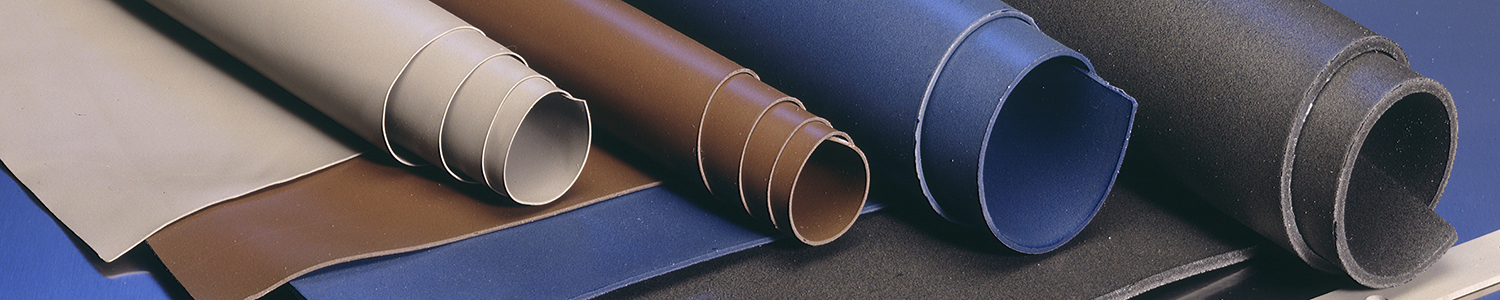

Four of the reasons why CHO-SEAL® conductive elastomer electromagnetic interference (EMI) gaskets are the right EMI shielding solution. Once used mainly to shield critical defense and aerospace electronic systems, Parker Chomerics conductive elastomers have become the progressive choice for designers of consumer, telecommunications, industrial equipment, automotive, medical devices and much more.

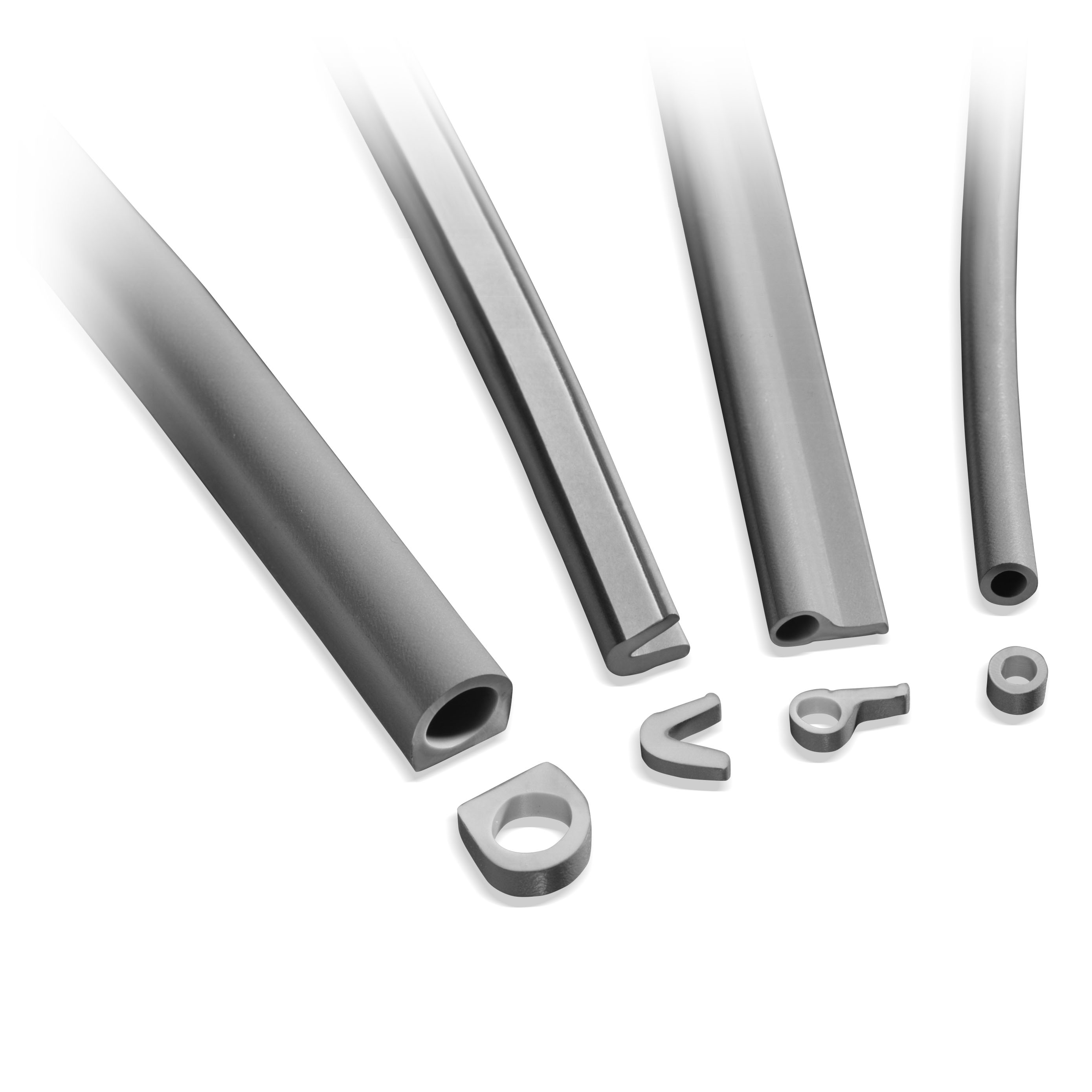

Conductive elastomers are reliable over the life of the equipment, and the same gasket is both an EMI shield and an environmental seal. Elastomer gaskets resist compression set, accommodate low closure force, and help control airflow. They’re available in corrosion-resistant and flameresistant grades. Their aesthetic advantages are obvious: almost any elastomer profile can be extruded or custom molded with modest tooling costs and short lead times for either prototypes or large orders.

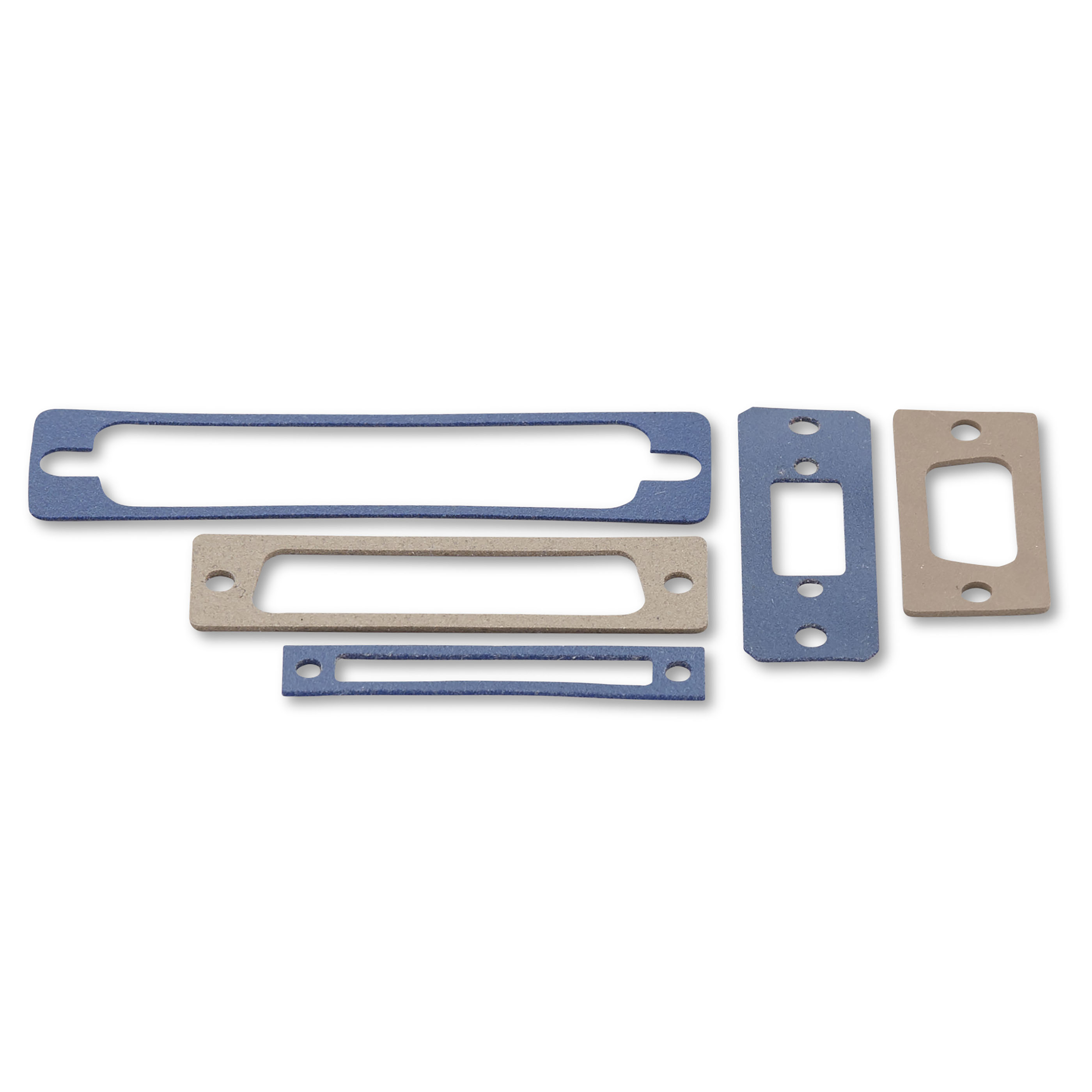

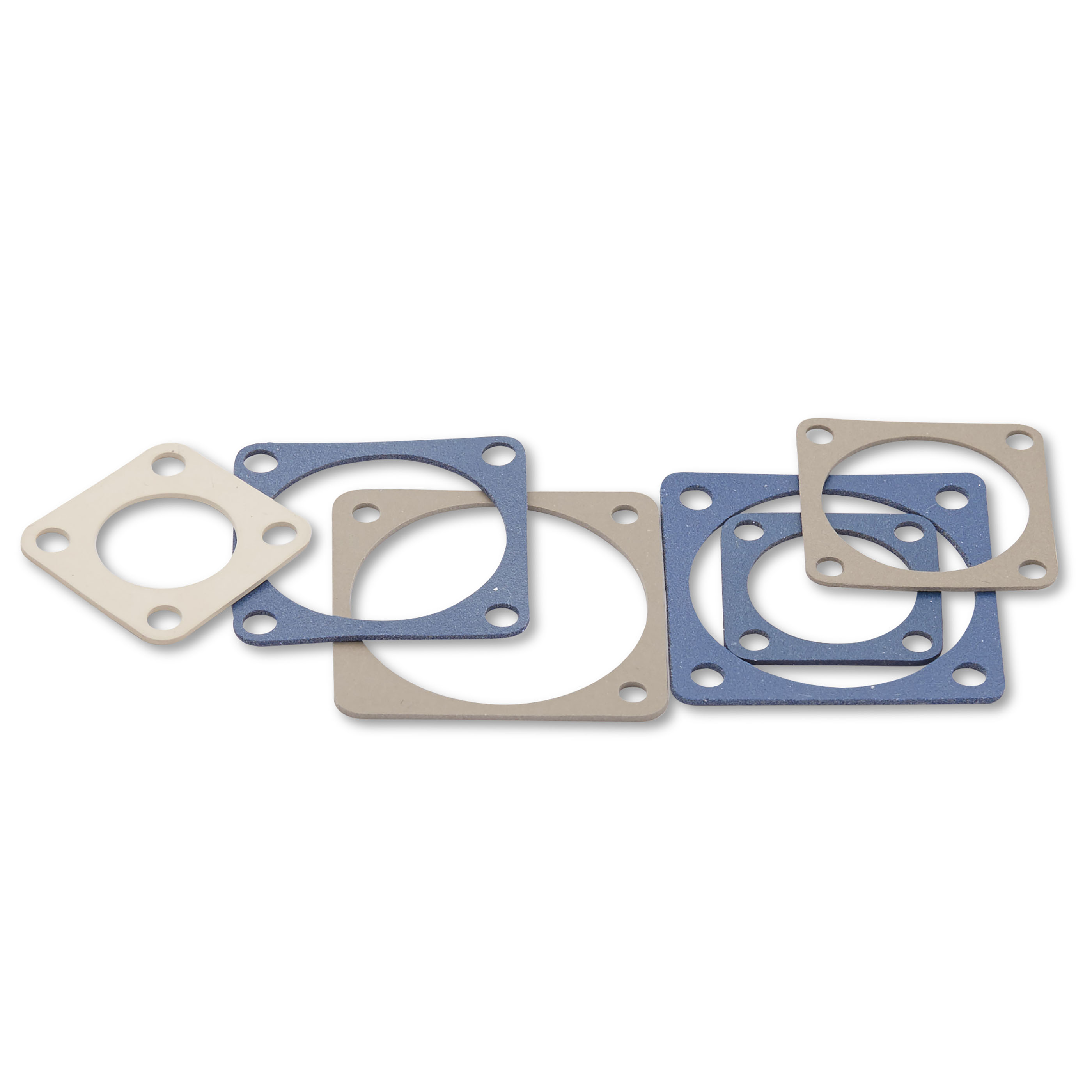

Parker Chomerics offers hundreds of standard molded and extruded products, but we can can also take a customer-supplied design and deliver finished parts. Molded products provide moisture and pressure sealing and EMI/EMP shielding when compressed properly in seals, flanges, bulkheads, and other assemblies. Extrusions provide similar benefits and are also readily lathe-cut into washers, spliced, bonded, kiss-cut, or die-cut to reduce installation labor and to conserve material, resulting in a cost-effective alternative to other methods of EMI shielding and environmental sealing.

Product Features and Benefits:

- Nearly any shape or design possible

- Many different filler material options available

- Cost effective while mantaining high performance

- Available in corrosion-resistant and flame resistant grades

Step 1. Determine Binder Material

It's very important to understand the level oc chemical resistance your EMI shielding elastomer gasket will require. Below is an example table of common exposures and fluids our customers are exposed to. Generally, a silicone gasket will be the right choice, however, there will be times -- especially in military or high end settings where an EPDM gasket is necessary.

| Exposure/Fluid | Silicone | Fluorosilicone | EPDM |

|---|---|---|---|

| High Temp | Excellent | Good | Fair |

| Low Temp | Excellent | Excellent | Excellent |

| IRM 901 (ASTM No. 1) Oil | Fair/Good | Good | Poor |

| Hydraulic Fluids | Poor | Poor | Poor |

| Hydrocarbon Fuels | Poor | Good | Excellent |

| Ozone, Weather | Good | Good | Good |

| Super Tropical Bleach | Poor | Fair/Good | Good |

| Dilute Acids | Fair | Good | Good |

Step 2. Determine Filler Material

Once you have determined the binder material that is appropriate for your application, it's time to determine the filler material. Our array of conductive elastomers offers true flexibility in selecting the appropriate material for a specific applications on the basis of cost and level of attenuation required. Price varies directly with shielding performance. Please view our Conductive Elastomer Engineering Handbook for further detail.

| Material | Filler | Binder | Shielding | Corrosion |

|---|---|---|---|---|

| CHO-SEAL 6502 | Nickel-Aluminum | Silicone | ★★★★★ | ★★★★★ |

| CHO-SEAL 6503 | Nickel-Aluminum | Fluorosilicone | ★★★★★ | ★★★★★ |

| CHO-SEAL 1298 | Silver-Aluminum | Fluorosilicone | ★★★ | ★★★★ |

| CHO-SEAL 1285 | Silver-Aluminum | Silicone | ★★★★ | ★★★ |

| CHO-SEAL 1287 | Silver-Aluminum | Fluorosilicone | ★★★ | ★★★ |

| CHO-SEAL 1215 | Silver-Copper | Silicone | ★★★★★ | ★ |

| CHO-SEAL 1217 | Silver-Copper | Fluorosilicone | ★★★★★ | ★ |

| CHO-SEAL S6305 | Nickel-Graphite | Silicone | ★★★ | ★★ |

| CHO-SEAL 6370 | Nickel-Graphite | Silicone | ★★ | ★★ |

| CHO-SEAL 6371 | Nickel-Graphite | Silicone | ★★ | ★★ |

| CHO-SEAL 6308 | Nickel-Graphite | Silicone | ★★★ | ★★ |

| CHO-SEAL 6330 | Nickel-Graphite | Silicone | ★ | ★★ |

| CHO-SEAL L6303 | Nickel-Graphite | Fluorosilicone | ★★★ | ★★ |

| CHO-SEAL 1350 | Silver-Glass | Silicone | ★★★★ | ★ |

| CHO-SEAL 1310 | Silver-Glass | Silicone | ★★★ | ★★ |

| CHO-SEAL 1273 | Silver-Copper | Silicone | ★★★★ | ★ |

| CHO-SEAL 1270 | Silver-Copper | Silicone | ★ | ★ |

| CHO-SEAL 1224 | Silver | Silicone | ★★★★★★ | ★ |

| CHO-SEAL 1221 | Silver | Fluorosilicone | ★★★★★★ | ★ |

| CHO-SEAL 1401 | Silver | Silicone | ★★★★ | ★ |

| CHO-SEAL 1239 | Silver-Copper | Silicone/Cu Mesh | ★★★★ | ★ |

| CHO-SEAL 1212 | Silver-Copper | Silicone | ★★★★★ | ★ |

| CHO-SEAL 6435 | Silver-Nickel | EPDM | ★★★ | ★★★ |

| CHO-SEAL 6307 | Nickel-Graphite | EPDM | ★★ | ★★★ |

| CHO-SEAL 6452 | Nickel-Graphite | EPDM | ★★★ | ★★★★ |

| CHO-SEAL 6460 | Nickel-Aluminum | EPDM | ★★★★ | ★★★★★ |

| CHO-SEAL V6433 | Silver-Nickel | Fluoro/Fluorocarbon | ★★★ | ★★★ |

| CHO-SEAL S6600 | Carbon | Silicone | ★ | ★ |

Step 3. Determine CHO-SEAL Gasket Configuration

- New product releases

- Updated support documentation and articles

- Existing product notifications

- The latest white papers, videos, and much more!