Technologies for Hydrogen & Fuel Cells

As a world-leading manufacturer of engineered components and systems for a wide range of fluid and gas handling applications, Parker has an established track record of successfully helping customers bring new technologies to market.

With hydrogen gaining momentum and seen as a leading energy source for the future, Parker is well positioned to support the newest applications – from processing and isolating the gas to transportation, storage and dispensing, right through to final use in its various forms.

We develop advanced products and technologies for hydrogen applications that increase efficiency, reduce cost and ensure safety. And using our expertise in other market sectors, we can also transfer existing technologies to provide hydrogen-ready solutions. Re-engineering components between different markets and applications can be cheaper and faster than developing them from scratch.

Find out how technology transfer can accelerate product development in our blog which considers the value of technology transfer for hydrogen applications.

Products and services for the hydrogen industry

Whether designed specifically for use within hydrogen applications or re-engineered from other industries, our products offer high levels of reliability and durability.

With fittings that can withstand extreme cold, heat and aggressive media, and hoses that prevent liquids from freezing in critical applications, our hydrogen-ready products include tubing, filtration components, control valves, dryers, pressure regulators and transducers, seals, tubing, heated hoses, chillers, asset management tools and large bore non-weld piping solutions.

Hydrogen Enquiry?

To find out more about technology for Hydrogen applications, please complete the form below and one of our team will get back to you .y

PRODUCT SPOTLIGHTS

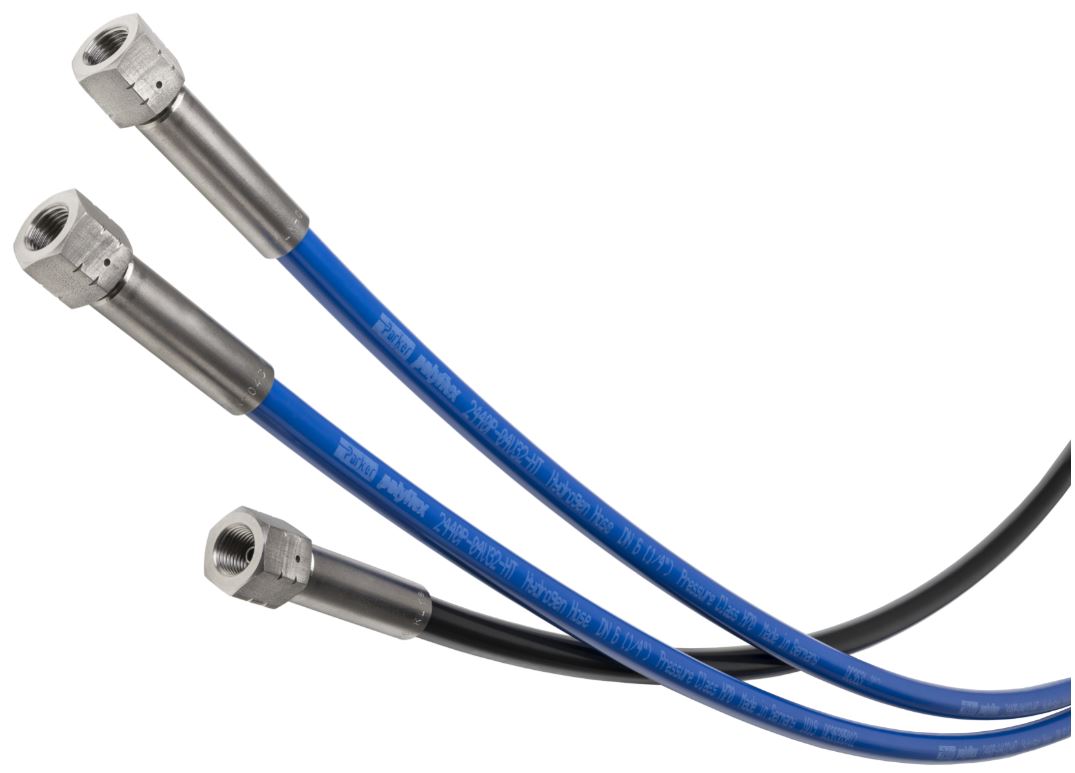

Thermoplastic Hose

Parker’s hydrogen hose is designed to match the challenging demands of high pressure hydrogen transfer providing fast refuelling and no leakage for pre-cooled hydrogen at -40 °C. The robust design offers a high level of reliability and an extended life cycle for use in 100 bar hydrogen fuel stations, and the tight bend radius enables more convenient usage and installation in limited spaces.

Heated Hose

Often hydrogen solutions exist in other markets and applications. Parker’s electrically heated hoses and tube blankets were originally created as a response to prevent Diesel Exhaust Fluid from freezing within diesel after-treatment applications. The technology is being adopted within the hydrogen market to stop the by-product of water freezing, to keep vent lines running, help in a constant ambient temperature and reduce downtime and maintenance.

See the links for the product information in its original application:

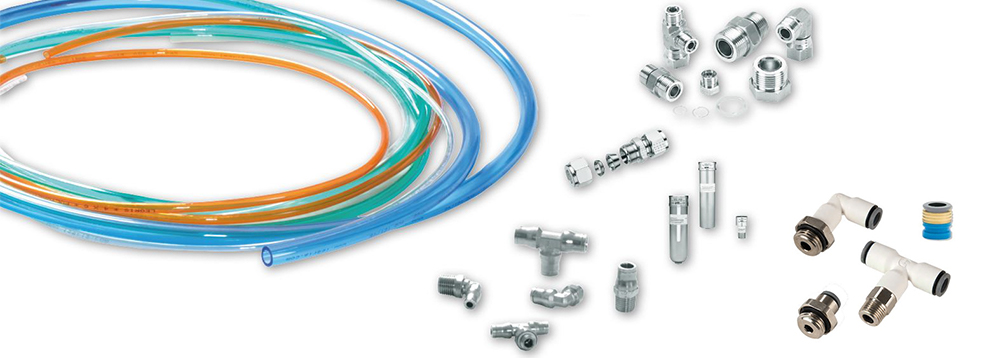

Tube Connections and Valves

Safely and effectively connecting hydrogen pipework and tubing is crucial and Parker continues to lead with the way with products engineered to optimise fuel conveyance. Both nut and ferrule type fittings and our flat face sealed varieties have EC79 approvals. This highlights their capability and robustness in on-vehicle applications and they can therefore be safely re-engineered for use within static hydrogen systems.

We offer certified training on the safe use and installation of these products.

Low Pressure Fittings

Fittings and connectors are often viewed simply as commodity parts, yet fittings have their own engineering challenges especially in critical applications and when passing corrosive materials. Parker’s plastic low-pressure fittings are strong alkaline-resistant with a wide temperature range to ensure safety and a long service life. Our stainless-steel fittings have excellent sealing properties for low pressure gases.

Filtration

Within hydrogen applications, filtration plays a crucial part in ensuring that cleanliness levels are met. Parker’s filtration and gas preparation solutions purify water and remove compressor oils, hydrocarbons and moisture to ensure the cleanest production of hydrogen while protecting critical components.

Parker Sales Company UK, Tachbrook Park Drive, Warwick, United Kingdom