Find the Right Form-In-Place EMI Gasket

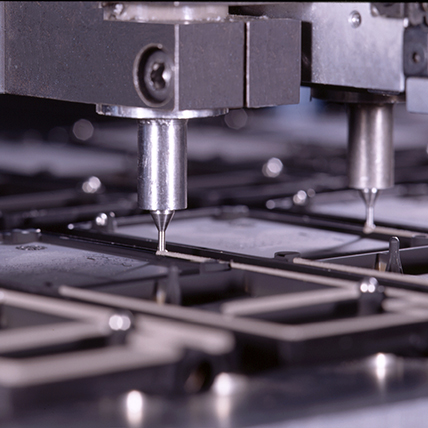

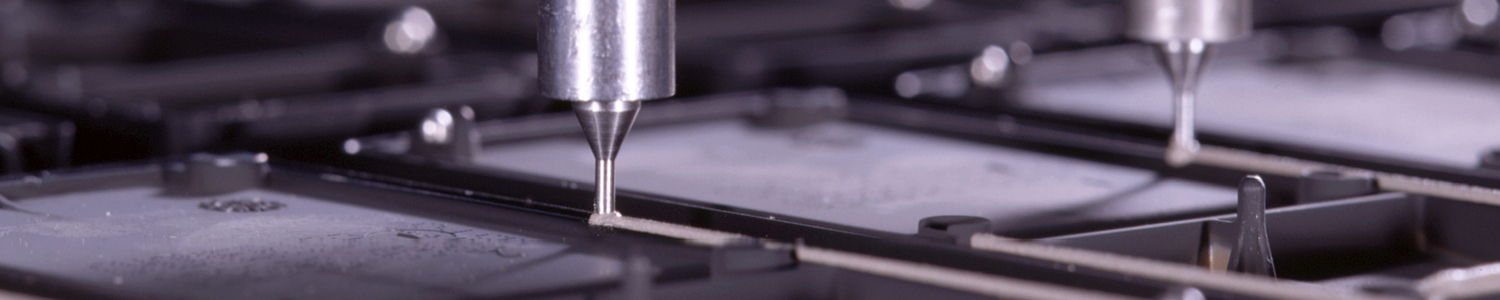

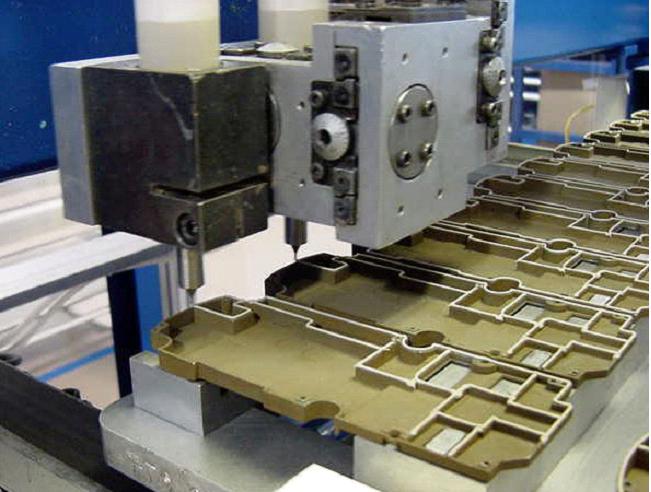

Parker Chomerics offers EMI shielded CHO-FORM® and non-conductive ParPHorm® form-in-place (FIP) gasket materials. FIP gaskets are robotically dispensed, which create precise gasket beads on metal and plastic housings. FIP gaskets provide the lowest total cost of ownership for small cross section and complex pattern applications. Parker Chomerics CHO-FORM and ParPHorm FIP materials may eliminate the need for nickel or tin plating and or secondary environmental gaskets, which can reduce the installed cost of an EMI gasket by up to 60%.

To achieve this performance, a range of particle technologies combined with thermoset and room-temperature-vulcanizing (RTV) silicone systems provide a material selection for most opportunities. Different filler options can balance material cost versus performance, and we can even provide low-cost alternatives for less demanding applications.

Parker Chomerics corrosion resistant materials inherently provide protection against galvanic activity. Parker Chomerics general purpose materials exhibit excellent electrical and mechanical properties on metallic and shielded plastic housings, while our silver filled materials provide high end shielding and conductivity critical for inter-compartmental shielding.

Excellent Shielding Effectiveness

CHO-FORM gaskets exceed 100 dB between 200 MHz and 12 GHz. Shielding performance increases with cross sectional dimensions.

Denser Packaging is Possible

Can be applied to walls or flanges as narrow as 0.025” (0.76 mm) and doesn't require mechanical retention.

Compared with groove and friction-fit designs, the positional accuracy and self-adhesive properties of CHO-FORM gaskets will typically save 60% or more space. This frees additional board space and allows for smaller overall package dimensions.

Small Cross Sections, Complex Geometries

Any gasket bead path can be programmed using CHO-FORM application technology. CHO-FORM produces reliable junctions between bead paths that provide continuous EMI shielding and environmental sealing.

Low Closure Force Not a Problem

CHO-FORM is ideal for low deflection force designs, or those whose mating surfaces have low mechanical rigidity. Nominal deflection of 30% using a mechanical compression stop is recommended. Deflection below 20% or above 40% is not recommended.

Which CHO-FORM Material is right for you?

CHO-FORM 5575

- Ag/Al filler

- Moisture cure

- 80 (Shore A)

CHO-FORM 5528

- Ag/Cu filler

- Moisture cure

- 40 (Shore A)

CHO-FORM 5513

- Ag/Cu filler

- Thermal cure

- 53 (Shore A)

CHO-FORM 5560

- Ni/Al filler

- Thermal cure

- 55 (Shore A)

CHO-FORM 5550

- Ni/C filler

- Thermal cure

- 55 (Shore A)

CHO-FORM 5538

- Ni/C filler

- Moisture cure

- 65 (Shore A)

CHO-FORM 5526

- Ag filler

- Moisture cure

- 38 (Shore A)

CHO-FORM 5541

- Ni/C filler

- Thermal cure

- 75 (Shore A)

Electrically Conductive Form-In-Place Material Gaskets

Parker Chomerics robotically dispensed Form-In-Place (FIP) EMI shielding gaskets provide the lowest total cost of ownership for small cross section and complex pattern applications. Parker Chomerics CHO-FORM (conductive) and ParPHorm (non-conductive) FIP materials can reduce installed cost of an EMI gasket by up to 60%.

Corrosion Testing of Conductive Elastomer and Form-In-Place (FIP) EMI Gasket Materials Against ENIG

This white paper analyzes and draws conclusions about key performance and manufacturability characteristics in both electrically conductive elastomers and electrically form-in-place gaskets against electroless nickel/immersion gold (ENIG) circuit boards.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

Empowering Your Business on a Global Scale

Parker Chomerics’ manufacturing operations span the globe, allowing us to serve you locally no matter where you are. We understand your unique needs and provide personalized solutions that cater to your specific requirements.

Can't find what you're looking for? Talk to one of our experts.