Replace Turbine Valves to Prevent Unexpected Shutdowns on the Plant Floor

As 7E and 7F turbine valves have been in service for 20-30 years, plant operations and maintenance leaders need to inspect these aging valves to avoid future downtime:

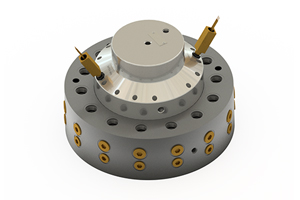

- Gauge Selector Valves

- Fuel Isolation Valves

- Water Staging/Isolation Valves

- Fuel Distribution Valves

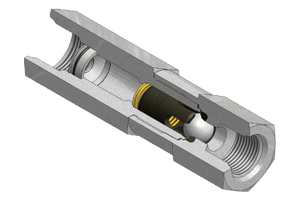

- Air Purge Valves

- Water Proportioning Valves

Parker Hannifin has launched the Valve Service Plan to replace or refurbish aged 7E and 7F turbine valves, which were originally branded as Dana-Gresen, and have been supported and manufactured by Parker for many years. This service plan will help keep you on task, avoiding downtime. With a readily available replacement valve on deck, productivity and efficiency don't have to slow down.

Watch our recent webinar on-demand below.

Download a FREE Resource Guide

Learn more about the benefits of our Legacy Valve Service Program. Complete the form below to download the guide. We will also email you a copy.

Valve Type

Valve Description

Potential Issues

Gauge Selector Valve

Allows for measurement of fuel pressure in the multiple lines supplying the combustion cans. This valve monitors the fuel pressure in each discrete fuel supply line going to the fuel isolation valve.

- Age of the valve

- Possible fuel oil pressure that leaks into the common port that leads to false pressure readings

- The handle may become hard to move

Fuel Isolation Valves

The check valves deliver fuel to one port per combustion can. This permits and prevents flow of fuel into the combustion cans.

- Age of the valve

- External corrosion due to aggressive environments

- Contamination can lead to pressure drops resulting in cold spots in the combustion can

Water/Staging Isolation Valves

The Water Staging/Isolation Valves control water used for NOx and temperature control and have the same number of ports as the gas turbine has combustion cans.

- Age of the valve

- External corrosion due to aggressive environments

- Internal wear and damage due to old, dirty and stagnant fluids

Fuel Distribution Valves

These liquid fuel distribution valves, which are mounted directly to the combustor, are used to distribute fuel to multiple nozzles located within the turbines' combustor cans.

- Dirty fuel may cause the poppet to "stick" over time

- Sticky poppet prevents the valves from opening and distributing fuel

- Contamination can lead to uneven firing amongst the turbines' combustor cans

Air Purge Valves

Air purge valves are designed to clear residual fuel oil from the delivery lines after the turbine has been running on liquid fuel.

- Leaving fuel residue in the lines can cause the fuel to dry out

- Fuel residue build-up can also clog the liquid fuel line

- Vintage of valve

- Sticking open or closed

- Leakage could allow fuel to backfeed into air lines

Water Proportioning Valves

These ball-style check valves are used to prevent backflow of combustion gasses into the water feed lines.

- OEM installed poppet style check valve often "chattered"

- OEM check valves also had difficulty in providing a bubble tight seal, allowing combustion gasses to leak upstream

- Chatter resulted in internal wear on metal seat/seal interface – leading to additional leakage

- Ball style check valve was designed with a high temperature soft seat – for a reliable bubble tight seal

- Chatter was eliminated with ball / cage design, resulting in longer service life

Parker’s Valve Service Plan is designed to replace or refurbish critical assets to minimize disruption to plant operations. The lifespan and vintage of these valves is reason to not ignore their current performance.

By purchasing a replacement valve, your plant can:

- Avoid downtime with quick replacement

- Save money by avoiding a shutdown

- Maintain steady production without any gaps

- Focus on other maintenance issues during national outages

If the potential issues are overlooked, the functionality of the valves could diminish, which would cause potential downtime or shutdowns.

©2021 Parker Hannifin Corporation | Privacy Policies