Beat CO2 supply issues with nitrogen on demand

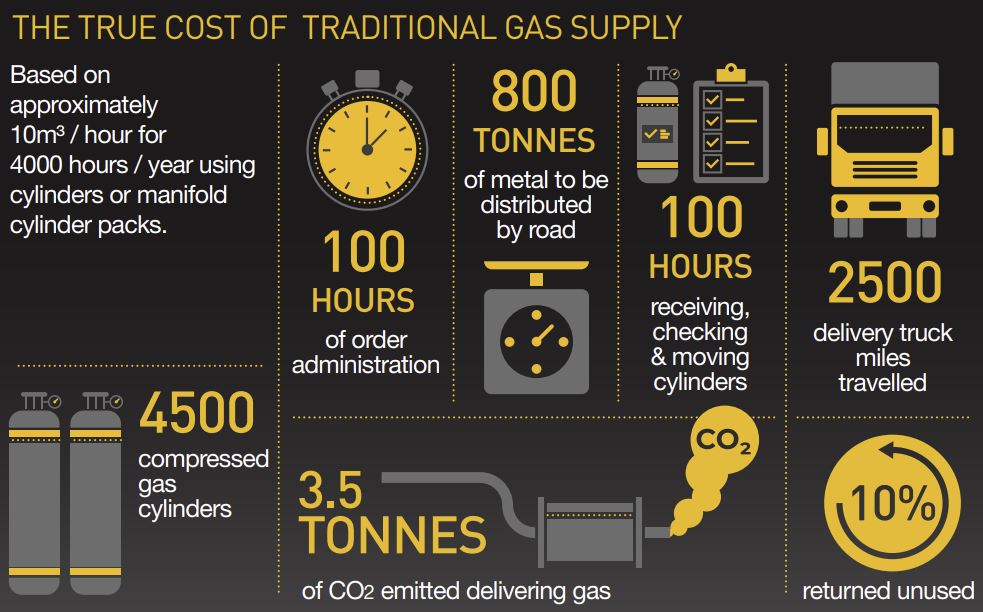

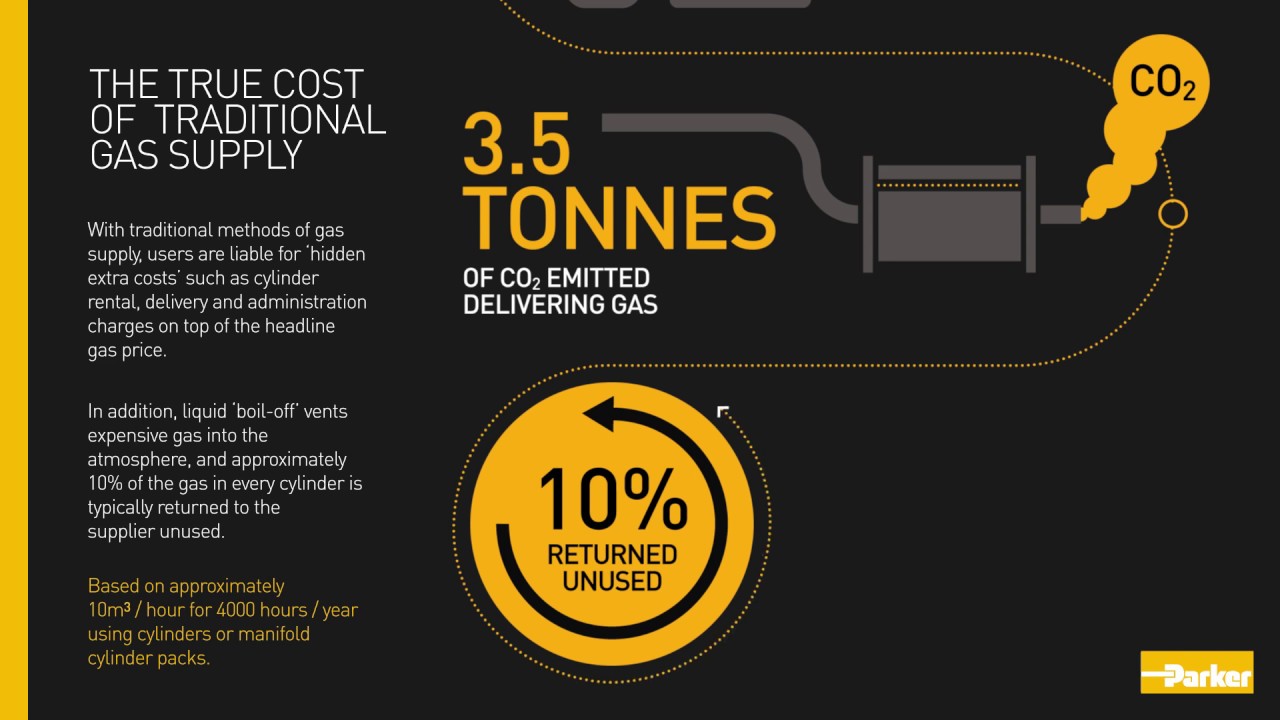

With CF Industries about to halt ammonia production at their Billingham plant because of the rising costs of gas and carbon, trade bodies have expressed concerns about the serious impact another CO2 shortage would have on the food, beverage and brewing industries.

Where CO2 is available, prices have risen sharply – in some cases up to 3,000% higher than last year.

Food grade nitrogen is an excellent alternative to CO2

Each time there’s a shortage of CO2, your output is at risk. But food grade nitrogen can replace CO2 in many of the production processes – storage, purging, kegging, blanketing, counter pressure filling – at a fraction of the cost of buying in gas.

NITROSource – nitrogen on demand

A Parker NITROSource on-site system generates nitrogen from pure compressed air to international standards as and when you need it. The system is compact but can be scaled up if your nitrogen requirements change.

- Safer – no storing or handling of high pressure gas cylinders or bulk liquid

- Cheaper – running costs are lower (potential savings of up to 90% compared to CO2)

- Greener – could reduce your carbon emissions by more than half.

It’s easy to switch to nitrogen

We’ll give you all the support you need to make the switch to nitrogen. So if you’re concerned about rising costs and interrupted supplies of CO2, fill in the contact form and we’ll be in touch.

Our experts will carry out a detailed site survey to help us understand your requirements and make recommendations for a NITROSource system that’s right for your business.

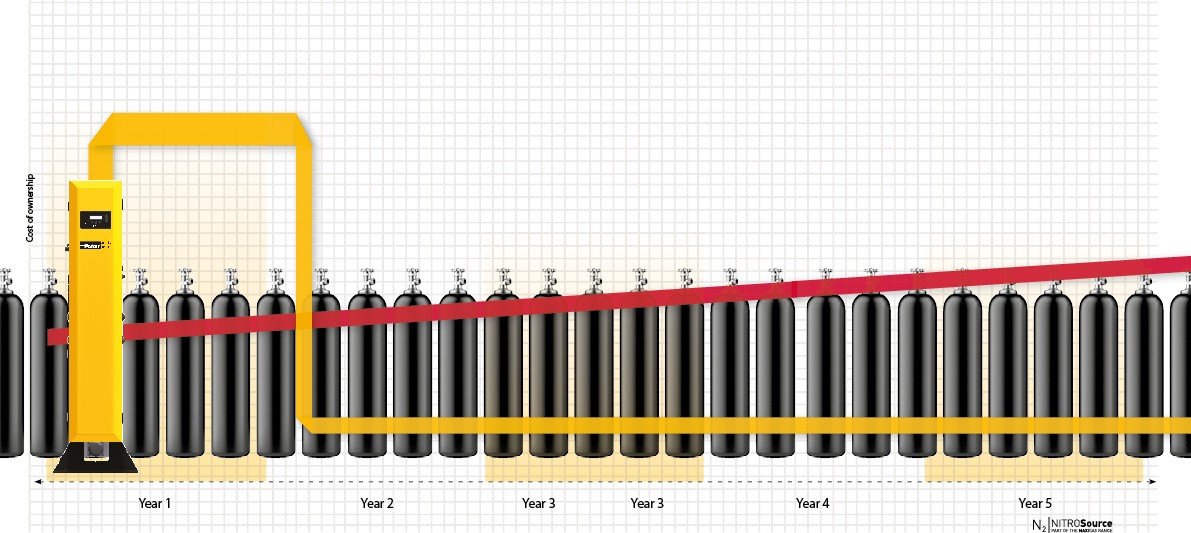

We’ll give you an estimated cost for installation and implementation – and you’ll also be able to see how much you can save by swapping CO2 for nitrogen, and how quickly you can capitalise on your investment.

Given the rising cost of CO2, it could be within a year.

ANY QUESTIONS ON NITROGEN GENERATION? LET'S TALK

Please submit the form and we'll be in touch very soon

The benefits of NITROSource:

- Produce food-grade nitrogen to European Standard E941

- No production downtime, no reduction in quality

- Remove the need for high pressure cylinder change-over or bulk liquid refilling

- System remain inert during clean down, with zero gas loss

- Long Life span (CMS lifetime assurance)

Video: Parker’s NITROSource: a new way of thinking about nitrogen

Case Study: blanketing application

“We have completely overcome our previous concerns with using CO2. The NITROSource on-site N2 generation package means that the business is in complete control over supply and costs”

Systems project manager

An independent drinks maker, concerned with rising CO2 costs and supply chain risks, approached Parker to discuss the possible benefits of using on-site compressed air to nitrogen generation technology.

The on-site survey showed that installing a NITROSource package would produce the volume and purity of inert nitrogen needed for the customer’s blanketing and product transfer applications, at a fraction of the cost of their existing carbon dioxide supply.

The customer ordered a Parker NITROSource nitrogen generator fitted with energy-saving technology. The new unit, delivered and installed by an authorised Parker distributor, generates a constant, uninterrupted supply of optimum quality nitrogen. The unit’s small footprint meant that minimal space was required inside the customer’s plant room whilst the modular design affords simple expansion should demand for nitrogen increase in the future.