Mobile Industrial Market

Why Is Seal Retention Important and Finding the Right PIP Seal

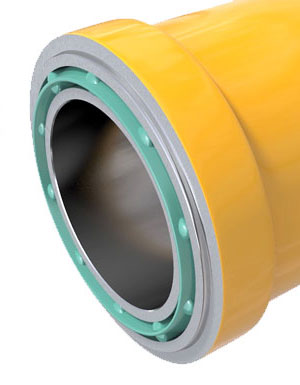

We receive many requests regarding seal retention but why is it so important? There are 3 main reasons: ease of component assembly, serviceability, and transit issues. For example, seal retention is important when you have complex groove paths where your groove wanders around bolts or ports. It is also valuable in improving operator ergonomics by reducing installation strain or fatigue in high volume applications. Additionally, seal retention improves serviceability by eliminating the need for liquid sealants which can be difficult to clean. Last but not least, seal retention resolves transit issues by ensuring seals are retained from workstation to workstation or if components are assembled in different locations.

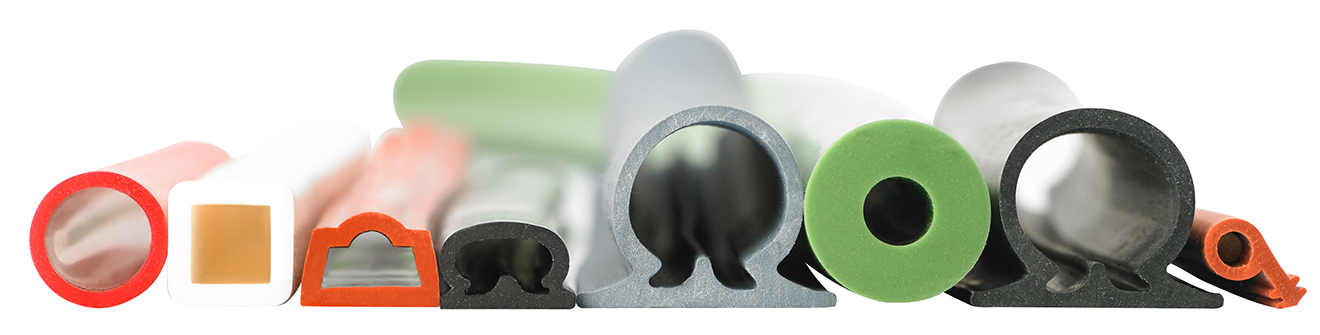

Parker offers an array of Press-in-Place (PIP) Seals to accommodate these application challenges. Additionally, each particular profile provides performance properties to address issues like larger tolerance stock, low seal load, and complex groove paths to name just a few.

Press-In-Place Benefits

Parker’s Press-In-Place (PIP) seals are custom designed to fit into complex groove patterns without having to be stretched. These custom seals are designed to withstand a wide variety of environments, fluids, pressures and temperatures.

In comparable seal heights, a standard PIP groove is 60 percent narrower than traditional grooves. Seal retention is achieved by sidewall interference, requiring no adhesives. The PIP design also maintains high pressure differentials, provides lower seal load, optimizes material use and is easy to install.

Compared to dispensed Form-In-Place (FIP) seals, PIP seals have several advantages. For example, during maintenance, PIP seals can be easily and quickly changed out, where FIP removal often damages the groove. FIP seals also require a considerable investment in machines and fixtures while PIP seals deliver higher performance and robustness without expensive tooling or fixture costs.

Parker offers a variety of PIP standardized profile options. These include:

- Molded Diamond—molded to the shape of the groove path using retention beads intermittently along the seal to keep it secure. This PIP seal can save space up to 60 percent versus traditional seals and allows a much smaller bend radius. The diamond seal can combine multiple parts into one and enables fast assembly. Applications include high volume automotive and low volume military programs.

- Hexapod—excellent for retention and lower pressure applications. It is also extruded and spliced which makes it a great choice for large enclosures. Applications include EV battery and heavy-duty engines.

- Keyhole—also extruded and spliced with reduces deflection and number of fasteners thanks to its low load. This PIP seal is also great for environmental sealing (little or no pressure) and larger tolerances, and is easy to install. Applications include plastic housings and stamped covers.

- Jigsaw—extruded and supplied in long lengths with no splicing required. The Jigsaw seal can be cut to size and requires no adhesive but does require a groove overlap. Applications may include multiple port sizes where just one part number can be used for the whole assembly, and in field installations where a pre-sliced or continuous part may be impossible to install.

- O-Ring—this seal is a good solution for retention and comes in three types: standard & custom sizes; extruded with spliced rings and cord stock; and custom molded plan view. Each type has its own benefits and limitations including cost effectiveness, bend radius, customized cross-sections and more.

- EZ-Lok—an axial seal designed for retention in dovetail grooves. the EZ-Lok seal is designed specifically to simplify and error-proof the installation process. In addition, this PIP seal minimizes seal wear on groove corners and removes the parting line from the sealing surface. It is currently used in the semiconductor market and is recommended when seal installation and performance are critical.

- Hollow O-Ring—extruded, spliced and low load which allows for a reduction in fasteners or clamps. They are easily customizable and are slightly oversized compared to the groove. However, they will not overfill the groove like a standard O-Ring. Like other hollow profiles, the Hollow O-Ring is not suitable for high pressure applications.

- Bulb—come in standard and custom profiles and are highly compliant to variation, i.e., your components to flex, run out, etc. If you have a groove that is already machined or spec’d in and you need a seal to fit, a custom bulb seal may be your best option.

Let's Discuss Your Application. Contact Us by email or chat.

Other retention options include: Friction Fit Hollow O; Friction Fit Hollow Profile; PSA on Profile; Dart Profile in Custom Groove; Dart Profile in FF Groove; Hollow Profile Mechanically Fastened; PSA on Hollow D; and Hollow Profile Pressed into Metal Track.

For help in determining the right solution for your application, please contact our O-Ring & Engineered Seals design team at OESmailbox@parker.com or 1-859-335-5101.

This blog was contributed by Samantha J. Sexton, marketing communications manager, Parker O-Ring & Engineered Seals Division.

© 2023 Parker Hannifin Corporation

Engineered Materials Group

O-Ring & Engineered Seals Division

2360 Palumbo Drive, Lexington, KY 40509

859-269-2351