Case Study

Parker CSS Division's Plate Manifold Technology Enables Greater Design Innovation for Next-gen Medical and Surgical Equipment

Application

In the dynamic field of minimally invasive surgery, continuous technological enhancements are key to improving equipment functionality and user experience. A prominent eye care company has embarked on a progressive initiative for its next-gen surgical equipment. Recognizing design and performance limitations of traditional multi-valve manifold sealing in their existing equipment, the company sought to overcome fluid and air flow management design challenges head-on with Parker’s plate manifold.

FEATURED PRODUCT: Plate manifolds bring a distinctive functionality to fluid and air flow management in medical and surgical equipment that paves the way for significant improvements

Challenge

The company's traditional surgical procedure equipment, though effective, faced challenges with its conventional fluid and air flow manifold systems. A key issue was the complex multi-component structure which relied heavily on numerous individual seals. This not only complicated the assembly process but also raised concerns about long-term reliability due to potential seal retention issues.

In response, the project set forth a critical goal: to reimagine the equipment's fluid dynamics and develop a more compact and efficient solution. The aim was to create a system that was not only easier to assemble and more cost-effective but also one that addressed the seal retention problems intrinsic to the previous design. By focusing on these improvements, the project sought to significantly enhance the reliability and overall efficiency of the surgical unit, aligning with the company's commitment to innovation and quality in medical technology.

Re-imagining next-gen medical and surgical equipment

Parker Solution

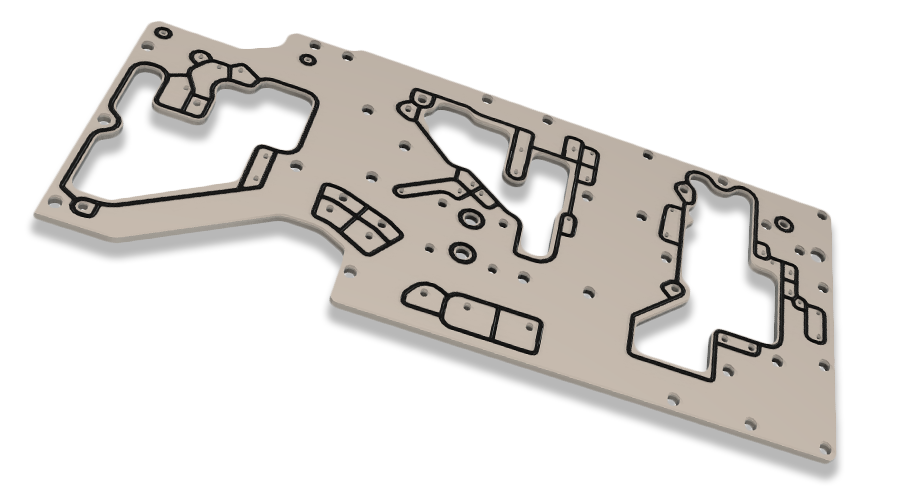

Inspired by aerospace innovations, the company, in partnership with Parker’s engineering experts, developed a multi-port overmolded manifold plate system. This system was ingeniously designed to optimize air pressure management, adapting flexibly to multi-port, multi-pressure requirements. It features dual sealing sides – one for air pressure sensing and the other facing the valves and controls – ensuring precise operation and reliability.

The streamlined design significantly reduced the number of individual seals needed, easing the assembly process. Advanced overmolded sealing was selected for maximum retention reliability, eliminating necessity of costly groove machining and mitigating likelihood of failure due to improper seal installation.

Impact

Plate manifold technology enhances efficiency, safety, and reliability of the surgical procedure device is promising. The technology is a significant design advancement for the customer. It expanded the customer’s freedom of design for their next-generation equipment, eliminates issues associated with complicated bill of materials (BOMs), and streamlines the assembly process.

The journey of adopting the manifold plate technology is a testament to the company’s power of innovative thinking. As a sealing technology leader, Parker CSS Division exemplifies engineering excellence in partnering with pioneering customers and delivering breakthrough solutions that not only meet current needs but also support future advancements.

Contact

Parker Hannifin

Composite Sealing Systems Division

7664 Panasonic Way

San Diego, CA 92154

(619) 661-7000

www.parker.com/css

NEED ENGINEERING ASSISTANCE?