Parker Precision Fluidics Blogs

Important Tips When Selecting Valves for Point of Care Testing Instruments

POCT systems require valves that can feature fast response time, high flow, and repeated actuations while maintaining precision control to ensure highly precise and accurate test results. The valves should be compared using critical performance requirements including leak rates, reliability, types of materials used and subsystem availability. In this blog, we will discuss key aspects to look for when selecting valves, and possible upgrades to increase reliability and efficiency.

Brushless DC Motor Technology in Miniature Pumps

Medical technology continues to evolve towards diagnosis and treatment equipment that is closer to the patient - wearable or in the home. Examples include point of care diagnostics, dialysis, compression therapy machines, and negative pressure wound therapy devices. Medical equipment manufacturers are responding to this trend by designing smaller, more portable, and quiet devices to improve the patient's experience and comfort.

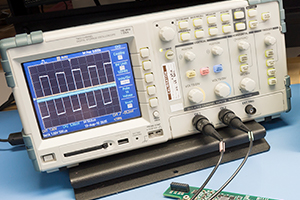

Pulse Width Modulation Control for Solenoid Valves

Pulse width modulation (PWM) is a method of reducing the average power delivered by an electrical signal, by breaking it up into predefined pulses. When utilized to operate direct acting solenoid valves, a PWM signal can result in significant power saving and heat reduction while maintaining the desired pneumatic function.

Capitalizing on Valve Mechanics With a Hit and Hold Circuit

Hit and hold circuits enable solenoid valves to be energized to full power and held for a short duration of time before voltage and current are reduced significantly to lower levels, while still allowing the valve to remain open and energized. Hit and Hold circuits enable OEM system designers to operate solenoid valves at a reduced input voltage rating while maintaining the intended valve function.

Basic Solenoid Valve Operation

Direct acting solenoid valves require a significant amount of electrical power to change from a normally closed state to an open or actuated state. Once the valve is fully actuated, the amount of electrical energy required to maintain this state is significantly lower than the initial energy required to initiate the actuation.

Tips for Selecting a Mass Flow Measuring Device

There are several technology options in precision measurement devices but the two that have frequently been compared against each other are thermal mass flow and differential pressure mass flow. These technologies are widely used in high purity applications including semiconductor, analytical and medical. Manufacturers in these industries tend to focus on one technology or both.

Benefits of Using IEC-60601 Compliant Components in Medical Devices

Developing and introducing a new clinical diagnostic instrument or medical device is a challenging accomplishment that often takes years. One of the final steps in bringing life-saving, life-improving equipment to the public is US FDA listing and CE marking processes that ensure the safety of these devices as well as their compliance to well-established global standards.

Extreme Performance Valve Provides Versatility in Life Science Applications

Highly sensitive instruments and equipment used in analytical chemistry and medical device applications require extreme capabilities. To provide unique differentiation of their products and meet their customers' challenging requirements, original equipment manufacturers (OEMs) rely on versatile state-of-the-art components.

Compamed Delivers on Energy-Saving Designs and Cost-Efficient Medical Devices

Compamed is a yearly international trade fair event located in Dusseldorf, Germany with a focus on delivering world-class high tech solutions for medical technology. This year the event occurred on November 16 – 19, 2019. Compamed 2019 featured approximately 750 exhibitors from over 40 countries and according to their official website, this year over 121,000 trade visitors attended the event.

Choosing a Solenoid Valve for Applications Requiring Extreme Performance

Today's state-of-the-art laboratory and medical instruments are smaller, more accurate and higher performing. Many applications, such as those in analytical chemistry (mass spectrometry and gas chromatography) and medical devices (laser therapy and hemodialysis) require extreme levels of performance. Instrument manufacturers require reliable, efficient, innovative components to stay competitive and meet the needs of new, demanding applications.

New Product Technology Introduced in Point-of-Care Testing Instrumentation

In clinical diagnostics, the fastest-growing segment is point-of-care testing (POCT). POCT consists of medical diagnostic testing performed close to the patient, instead of a traditional centralized hospital lab or offsite laboratory. Driving this growth and market demand is the ability to bring convenient testing and almost immediate results to the physician and patient. The market is also very broad, as point-of-care tests can be developed for many clinical indications including infectious diseases, glucose, cholesterol, cancer (tumor marker testing), urinalysis, diabetes, cardiology and blood screening.

Subsystems are Critical to OEM Instrumentation Design

Life science instruments in the medical, analytical and diagnostics fields vary widely by technology and design. But one thing they all have in common is the complexity of their fluidic circuits. As market dynamics continue to push for reduced prices, maximized use of laboratory space and portable devices, it is becoming increasingly important for OEMs to optimize their instrument designs to meet these demands. One such way to achieve this is to partner with an experienced manufacturer who can supply purpose-built engineered subsystems.

Point-of-Care Testing Requires Microfluidic Precision

Point-of-care testing (POCT) is a rapidly expanding segment of the healthcare industry. This expansion is driven by an increasingly diverse array of advanced medical diagnostic equipment that can be used at or near the point of care, which leads to easier testing and faster clinical decisions. POCT equipment measures a wide range of health indicators, including pathogen detection, electrolyte concentrations, cardiovascular markers, cholesterol, drug levels, urine chemistry, infectious diseases, organ function, and immune response.

New Miniature Proportional Valve for Next Generation Ventilators

One of the most important medical devices created in the last century is the ventilator. The ventilator is critical for patients who cannot breathe on their own due to medical procedures or long-term respiratory ailments. The significant impact the ventilator has had on the medical industry has made the device an essential piece of emergency care, intensive care, and anesthesia delivery.

What is ISO 14001:2015 and Why Is It Important for Parker Precision Fluidics

ISO 14001 is recognized as the international standard for environmental management systems and provides organizations/businesses with criteria to follow, which will identify, control, and reduce their environmental impact. Becoming ISO 14001 certified has numerous benefits to businesses, sectors, and activities large or small. ISO 14001 is a voluntary standard that hundreds of thousands of companies worldwide have chosen to become certified in, uniting them in a global goal to reduce the environmental impacts created by companies and businesses, to preserve the natural Earth for future generations.

Advanced Liquid Valves Expand Microfluidic Possibilities

Liquid valves are a critical component in the next generation of analytical equipment used for clinical diagnostics, analytical chemistry, environmental monitoring, agent detection, and other life science applications.

To meet customer’s needs, lab managers want smaller-size diagnostic and analytical equipment with improved sensitivity and reduced reagent consumption—as well as lower operational costs. Finding the balance between improving system performance and managing the bottom line is a challenge for any design engineer in the laboratory instrumentation market space.

What's the Difference Between Volumetric Flow and Mass Flow?

What type of flow measuring device should I use? This is a recurring question. The choice is bounded by customer needs, product variables and different technologies available on the market today. It’s important to find a vendor with extensive knowledge in flow technology to guide you in your purchase. Selecting the wrong flow measuring instrument can result in inaccurate data and increased the cost from maintenance/replacements and upgrades. This blog focuses on two specific types of measuring devices: Rotameters (a variable area flow meter) and Thermal Mass Flow devices. We will outline how both devices work and highlight important specifications to look for when purchasing.

Important Tips When Selecting Valves For Analytical Instruments

Valve technology has come a long way with many available features. Gas and liquid multimedia valves that are used in chemical analysis such as Gas Chromatography/Mass Spectrometry (GC-MS) and Liquid Chromatography/Mass Spectrometry (LC-MS), two analytical techniques, are used for chemical analysis and have very critical requirements. In this blog, we will discuss key aspects to look for when replacing a solenoid valve, and possible upgrades to increase reliability and efficiency.

The Importance of Reliability in Diaphragm Pumps

Reliability is the quality of being trustworthy or of performing consistently well. Here at Parker, we’ve made reliability the focus of our products since the company was established; this has made Parker’s products synonymous with reliability. The new BTX-Connect diaphragm pump meets next-generation manufacturers' needs for reliability, portability, noise reduction, and adds additional advanced technology that is revolutionizing miniature diaphragm pumps.

How Can Clinical and Analytical Chemistry Labs Increase Throughput?

Clinical and analytical laboratories are under constant pressure to increase throughput. Throughput is the amount of material or items passing through a system. In this case, it’s analyzing a higher volume of samples per day. This brings several advantages: reduced cost per sample, decreased sample turnaround time, fewer instruments needed, and reduction of laboratory space required. These reasons, among others, are why laboratory managers are pushing instrument manufactures to increase their throughput.

Reducing the Noise Impact of Medical Devices

Medical-care settings are often stressful, making it hard to rest or sleep—both of which are important for healing and recovery. And, as the portability of medical technology continues to rapidly evolve, an increasing number of medical devices and instruments can be utilized in the patient’s home—for example, point-of-care diagnostics, dialysis, and portable oxygen concentrators.

For the best possible experience, medical equipment should be as non-intrusive as possible.

Choosing a High Flow Proportional Valve for Ventilators and Anesthesia Machines

In today’s medical device industry, there is strong demand for smaller, sleeker designs and speed to the market with the newest breakthrough products. Engineers designing respiratory equipment, such as ventilators and anesthesia machines, are challenged by a host of critical factors. Users demand top performance and compliance with evolving regulatory standards. Medical device original equipment manufacturers (OEMs) must address these challenges by producing equipment that meets design specifications and performance expectations while also controlling costs.

Fluidic Components Take the Pain Out of Designing Capnography Monitors

To meet the needs of today's ever-changing hospital environments, medical equipment manufacturers are under pressure to design smaller, lighter and more portable devices without compromising functionality. Medical device engineers are challenged with integrating components that meet design specifications, yet also deliver the high performance expected for critical applications.

A capnography monitor, for example, is a medical device used by anesthesiologists in the operating room or in intensive care units to capture, measure and display readings on the exhaled carbon dioxide (CO2) of a patient

New Miniature Poppet Solenoid Valve Increases Battery Life

Some of the biggest challenges for designing battery operated, handheld medical devices are size, weight and battery life. All three can be significantly improved by using our new miniature solenoid poppet valve.

Called the Series LX, the valve's miniature size and low weight allow easy integration into small, portable devices. Only 8 mm in size, it provides highly reliable pneumatic on/off control for critical applications, delivering up to two million open/close cycles for a standard lithium AA battery.

How to Integrate Motor Speed Control for Pump Motors in Medical Devices

Providing miniature size, light weight and low power coupled with integration capabilities for pump and motor units in medical devices provide an ideal solution for design engineers. They are now able to design a more portable device that fits all the performance their customers demand into a package that takes up less space. The next challenge is to implement.

Mini Subcomponents for Medical Devices Make a Big Design Difference

Miniaturization is big in all fields these days. This trend is a challenge for machine designers faced with packing the same capabilities into a smaller space. Take the life sciences, for example. Medical device manufacturers continue to offer more portable devices in their portfolios, which forces the design engineer to fit all the performance their customers demand into a package that takes up less work space.

Meeting the Biocompatibility Challenge in Respiratory Device Designs

Design engineers face the challenge of improving system performance and capability, while they remain under constant pressure to reduce system cost. Meeting these challenges—along with meeting the need to comply with biocompatibility standards—is increasingly difficult in today’s global market.