Problem Solved!

Application Success Stories

From initial concept to production, Parker's engineering teams support many of the world’s leading manufacturers in the ever changing trends of the industry, helping them to expand their geographical footprint and achieve optimal operational efficiency.

Coolant Resistant FKM Materials Designed for Extreme Performance in Engine Design

Explore the groundbreaking advancements in sealing applications for engine design in our upcoming article. We delve into Parker's innovative development of multiple coolant resistant (CR) FKM materials, designed to enhance performance under the corrosive conditions of exposure to coolant and oil at high temperatures. The article provides an in-depth look at the evolution of cylinder liner seals, the introduction of coolant resistant FKM materials, and the elimination of the backup seal. Discover the three generations of these materials, each tailored to resist extreme performance requirements and extend service life across various vehicle types. The article also highlights the extensive testing of these materials with various coolant technologies. Stay tuned for this insightful exploration of Parker's OES Division's ongoing innovation in providing high-performance materials for future Mobile Industrial and Automotive challenges.

Sealing Challenge:

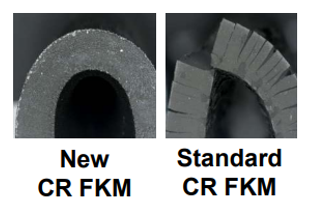

Sealing applications with exposure to coolant and oil has been a challenge for engineers working on engine design for decades. Parker has developed multiple coolant resistant (CR) FKM materials that improve performance in the corrosive conditions of exposure to coolant and oil in high temperatures.

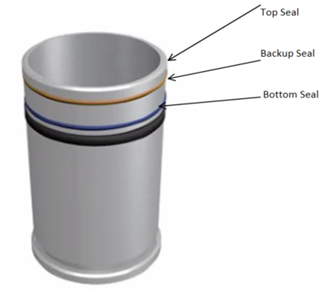

Cylinder liner seals were originally designed with a combination of an EPDM or AFLAS O-ring to seal the coolant, an HNBR backup ring and an FKM O-ring to seal the oil. EPDM is the best material for compatibility with coolant but swells with exposure to oil. FKM material has the high temperature resistance and compatibility with oil but can crack with exposure to coolant. After prolonged use, the coolant and oil would eventually degrade the seals due to small leaks or see more immediate failure if the O-rings had been switched during assembly. Parker developed coolant resistant FKM to solve this problem and eliminate the backup seal.

An older liner seal design

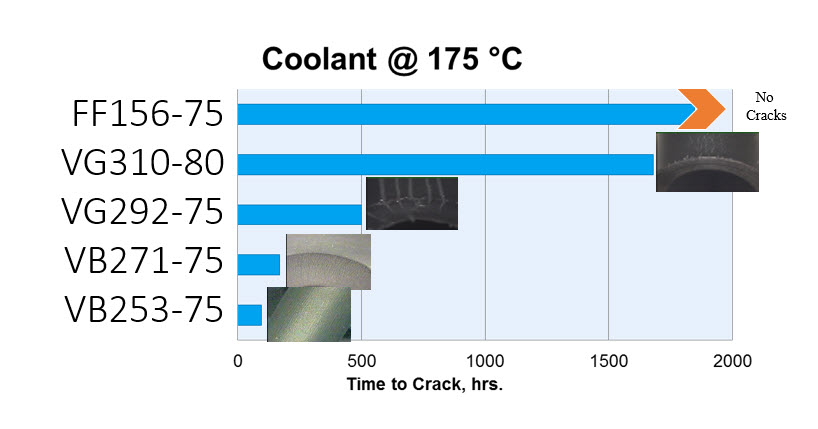

Comparative Chart

Sealing Solution:

Now, Parker’s material portfolio includes three generations of coolant resistant FKM materials to resist extreme performance requirements as temperatures increase and we see increased service life. 1st generation coolant resistant materials VB253 and VB271 provided the performance required up tp 135°C in coolant in trucking. 2nd generation materials VG292 and VG323 have satisfied customers with performance up to 150°C in commercial trucks, light duty trucks, and automobiles – including many electric and hybrid vehicles. 3rd generation, VG310 was developed for higher temperatures up to 175°C and prolonged use in challenging longer duty cycles. For extreme performance requirements, cost effective FF156 is another option for even longer service life.

O-Rings, D-rings and other shapes can be molded with coolant resistant FKM for the most extreme engine applications.

Materials have been tested in the following coolant technologies:

- OAT (Organic Acid Technology)

- IAT (inorganic Acid Technology)

- NOAT (Nitrited Organic Acid Technology)

- Glycol (mix of glycol or propylene glycol and water, the most basic coolant)

- HOAT (hybrids that combine IAT and OAT)

The O-Ring & Engineered Seals (OES) Division continues to innovate and provide high performance materials for the next generation of Mobile Industrial and Automotive challenges.

For more information on Parker's custom sealing solutions and materials, visit us at www.parker.com/oes.

Webinar: Navigating Critical Sealing Solutions & SAF

As the aviation industry continues to evolve towards sustainability, the role of SAFs have become increasingly significant. However, their unique chemical compositions present new challenges for the durability and performance of rubber seals within aircrafts. Join us for a deep dive into the crucial intersection of Sustainable Aviation Fuels (SAFs) and rubber sealing technology in our January webinar.

Parker Hannifin Corporation

O-Ring & Engineered Seals (OES) Division

2360 Palumbo Drive

Lexington, KY 40509

© 2023 All rights reserved.