CASE STUDY

Thermal Gap Filler Pad Solution for On Premise Supercomputer

A global IT company who designs and manufacturers on-premises and cloud storage required a customized thermal gap filler pad solution for their next generation of supercomputers.

A supercomputer consists of a multitude of customized components, combined into a single unit. Used to process enormous amount of data, at extreme speed, supercomputers can be challenging in terms of thermal management. With extreme speed comes extreme heat which needs to be managed so the supercomputer operates efficiently and reliably.

Thermal Material Caused Premature Failure

- The customer required a 3.0 W/m-K thermal conductivity gap filler pad solution for their next generation supercomputer, to replace a competitor’s thermal interface material which was unsatisfactory and causing premature failure of systems.

- Each module contained multiple racks which contain approx. 100 processor/DIMM memory blades that need a customized thermal interface material on both sides of the memory blade.

- The current assembly process was challenging and resulted in longer manufacturing lead times.

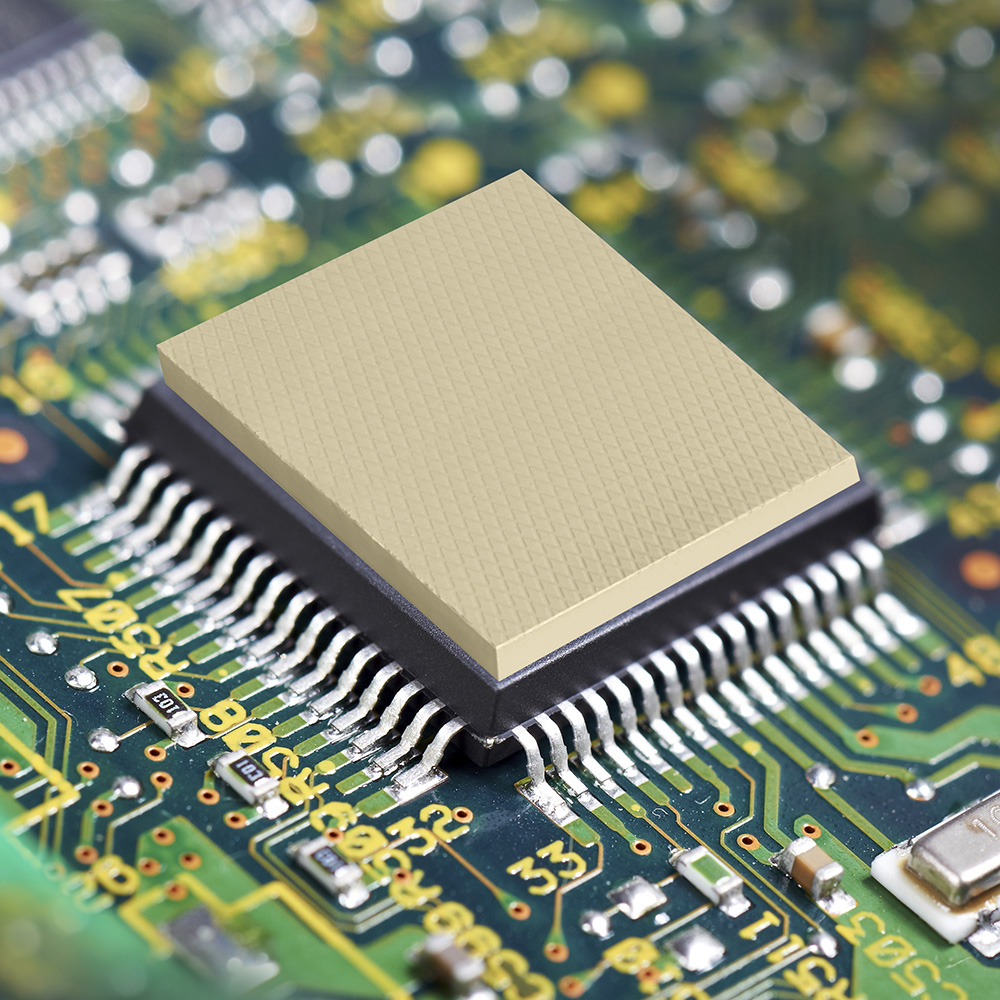

Thermal gap filler pad pictured on a heat generating chip.

Increase Speed of Assembly, Customized Solution

- Parker Chomerics was tasked with designing a customized thermal gap filler pad for this specific application and to improve the assembly process so material could be applied at speed and with ease.

- A thin thermal gap filler pad was required due to the narrow space between blades.

- The solution needed to be robust and extend the product’s life cycle.

Key Program Requirements

- An extra soft thermal gap filler pad material was required to minimize the stress on the memory blade and to maximize heat dissipation.

- Thermal gap filler pad material had to be tacky so easily compressed and stay in place on memory blade.

- 3.0 W/m-K thermal conductivity.

- An economically priced solution was required due to the large volume of material required.

- A global supplier was required so parts could be fabricated and shipped locally to the customer’s manufacturing plants across the globe.

- The application area was narrow, and the gap filler pad needed to slide in easily between the memory blades without sticking to other components.

Parker Chomerics Developed Thermal Solution

Parker Chomerics application engineers designed a customized solution of THERM-A-GAP 579PN, at a thickness of 1.5 mm and with a foil carrier that can slide in between the blades but still offer excellent thermal properties. This thermal gap filler pad has a thermal conductivity of 3.0 W/m-K, sufficient to meet the thermal challenges of the supercomputer.

The THERM-A-GAP 579PN was designed with a grove down the middle so the material could be folded over the top of each memory blade for easy application.

THERM-A-GAP 579PN has a PEN film (polyethylene naphtholate) carrier which stays in place after application and helps secure the pad around each blade. This carrier permits the gap pad to see a shearing motion and offers a clear, cost-effective dielectric film to the gap pad. THERM-A-GAP 579PN has ultra-low deflection force which is ideal for this type of application.

Parker Chomerics manufactures and ships the solution globally, in line with the customer’s requirements. Learn more about THERM-A-GAP 579 and the rest of the THERM-A-GAP family of thermal gap filler pads from Parker Chomerics now.

LET'S DISCUSS YOUR APPLICATION

Sign up for the Parker Chomerics monthly newsletter and keep up to date on everything Chomerics.

By signing up, you'll be the first to know:

- New product releases

- Updated support documentation and articles

- Existing product notifications

- The latest white papers, videos, and much more!

Parker Hannifin Chomerics Division

77 Dragon Ct., Woburn, MA 01801

781-935-4850