Introducing

THERM-A-GAP GEL 75

A thermally conductive gap filler

- The highest thermal conductivity dispensable thermal interface material from Parker Chomerics

- 7.5 W/m-K thermal conductivity with 30 g/min flow rate

Parker Chomerics THERM-A-GAP GEL 75 is a high-performance, dispensable thermal interface material with 7.5 W/m-K thermal conductivity. Part of a family of one-component dispensable gap fillers, THERM-A-GAP GEL 75 was developed to conduct heat from electronics to a heat sink or enclosure.

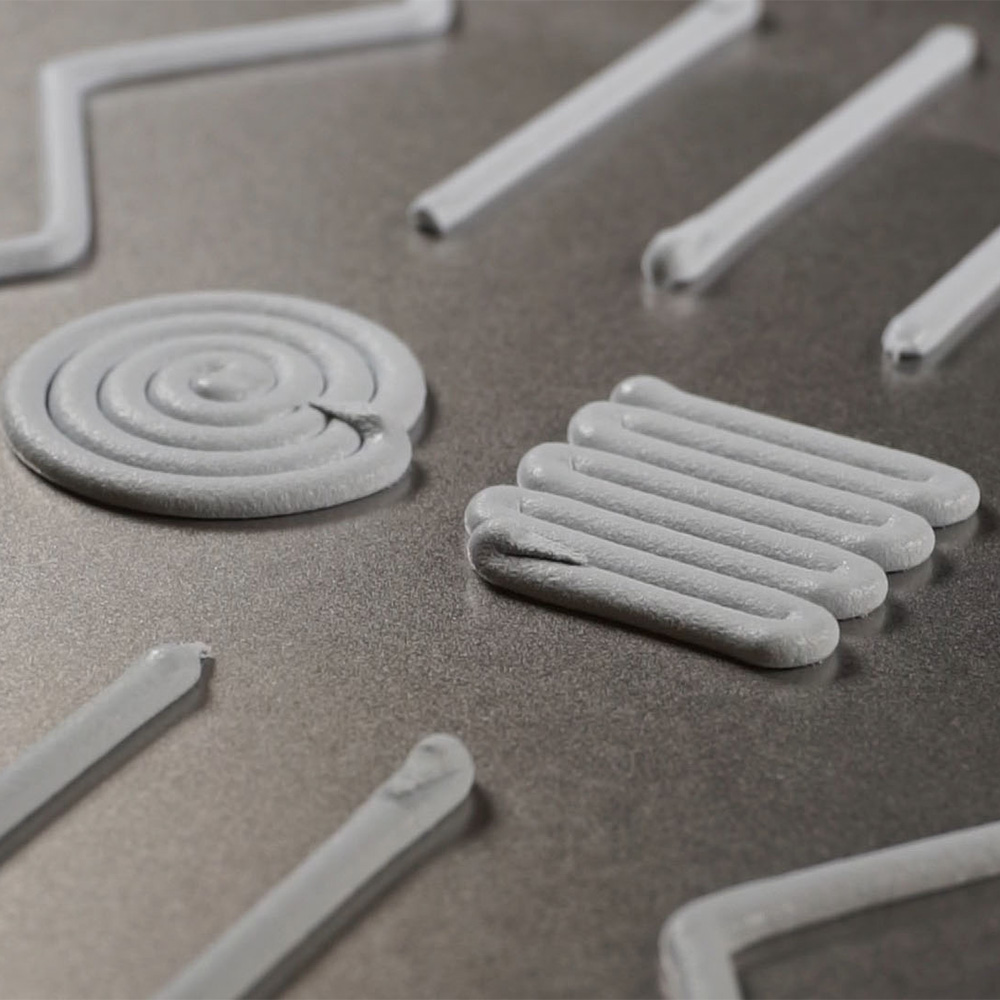

The heavy paste-like consistency of this thermal putty enables controlled dispensing, applied in variable thicknesses to suit application needs. THERM-A-GAP GEL 75 requires low compressive force to deform under assembly pressure, subjecting components, solder joints and leads to minimal stresses.

THERM-A-GAP GEL 75 is formulated to accommodate the thermal compound requirements of today’s high-performance electronics and is ideal for automated dispensing machines, rework and field repair situations. Parker Chomerics is a global leader in designing and producing dispensable thermal gels and thermally conductive gap fillers.

Product Features of THERM-A-GAP GEL 75, a Thermal Gap Filler

- Thermal conductivity: 7.5 W/m-K

- Easily dispensed thermal paste

- No secondary curing required

- Low thermal impedance

- Very low compression force

- Reworkable

Typical Applications for Thermally Conductive Gels

- Telecom base stations

- Power supplies and semiconductors

- Memory and power modules

- Microprocessors

- Central processing units (CPUs)

Get a Free Sample of

THERM-A-GAP GEL 75

Get a Quote Now

Tell us a little bit about your problem and we'll do our best to come up with a cost effective, timely quote to help you get started.

- Request a Quote

- 781 935 4850

- choquotes@parker.com

- Find a Salesperson

- Find a Distributor

RESOURCES

Design Guidelines for Grounding, Shielding and Thermal Management in Wi-Fi 6E and Wi-Fi 7 Gateways

Lightning-fast speeds and effectively imperceptible latency are no longer a part of the conversation for the future of connectivity, but rather are already available to consumers. With the recent rollout of Wi-Fi 6E and the upcoming rollout of Wi-Fi 7, consumers and networking hardware manufacturers have a whole lot to be excited about. To meet the challenges of advancing technology, designers must look to the next generation of thermal interface materials and EMI shielding/grounding solutions.

What Are THERM-A-GAP GELs?

THERM-A-GAP GELs are highly conformable, single-component thermal dispensable compounds that require no cure. Once dispensed, they hold their shape and are ideal for applications where stability and long term reliability is required. They are available in silicone and silicone-free formulations and are ideally suited for high volume applications.

Related Products

Top 5 Questions and Answers on Thermal Interface innovations for Consumer Electronics

Parker Chomerics has been busy developing new, next-generation thermal interface materials specifically to help aid in the thermal cooling of consumer electronics devices. Successful thermal management of high-power electronic components (single chips, multi-chip modules, integrated circuits, etc.) with high heat dissipation ratings requires careful design engineering.

How to Select a Thermal Gel or Thermal Gap Pad

Parker Chomerics has a robust line of thermal interface materials. It can be challenging to decide which one is best for your project. In this webinar, our product manager and engineers will help you decide which THERM-A-GAP product will work most effectively for you.

Overcoming Challenges of Fully Autonomous Vehicles

As the automotive industry moves toward more automated, connected vehicles, engineers are challenged to identify technologies that can process and transfer large volumes of data in real-time without adding significantly to the price of the vehicle.

Embrace the Global Advantage in Manufacturing

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.